Mantle TrueShape Advances Medical Mold Manufacture

In a recent case study, Mantle’s 3D-printed inserts enabled a medical device manufacturer to reduce 12-week lead times for prototype mold production to 4 weeks and at one-third of the cost.

A global medical device manufacturer recently participated in a study with Mantle Inc. to evaluate the lead time, cost and quality of Mantle’s printed inserts — developed via its TrueShape precision metal 3D printing technology — to produce dimensionally critical medical parts that are injection molded in a high-temperature thermoplastic.

Because of the medical device industry’s emphasis on quality and patient safety, new product introductions can be time-consuming and complicated when traditional processes and materials are used. For many medical parts, the production materials and the production manufacturing process must be used during prototyping and testing to ensure safety and performance. This requirement means that 3D-printed plastic parts often cannot be used during the prototyping phase. Instead, durable injection mold tooling is needed for initial prototyping and later-stage trials.

Moreover this manufacturer’s product is a complex, precise component that requires a thermoplastic that is challenging to mold because it requires high temperature and high pressure. Making a prototype tool for the product would normally take 12 weeks. Such long lead times would slow down the manufacturer’s ability to develop and launch the product.

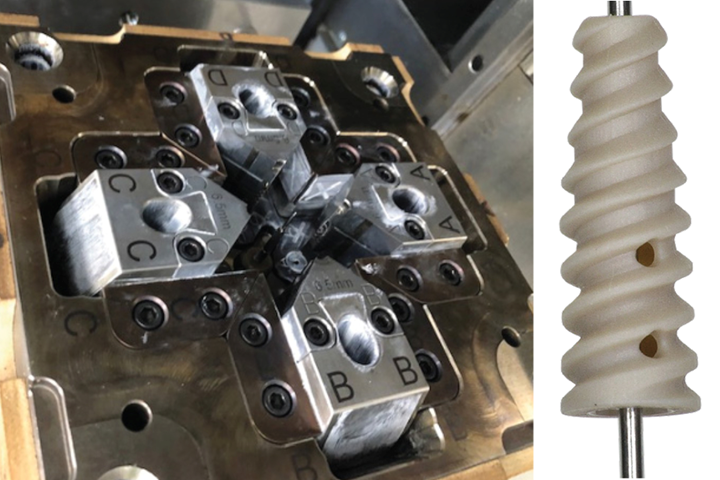

For this study, Mantle’s TrueShape technology and P2X material were used to print four slide-nose detail inserts. The inserts were printed in 39 hours, with a total production time for all four parts of 156 hours. The inserts, as supplied, are said to have required no work to meet surface requirements, since Mantle’s printing technology repeatedly achieves a surface finish of 1-3 surface roughness (μm Ra). Furthermore, the parts were accurate within 0.001" (0.025 millimeter) for all critical dimensions. The only post-processing required on the insert geometry was to grind the faces to the shutoff and to cut in a 45-degree dovetail on the backside of the noses via wire EDM so the noses could be inserted in the mold.

When evaluated, all four inserts were reported to have behaved just like standard P20 steel during EDM and machining operations. Once the grinding and wire EDM work was completed, which took a total of 160 hours, the molds were installed in an existing injection tool. A high-temperature engineering thermoplastic was run for 16 hours and produced 1,800 parts. Afterward, the parts were subjected to metrology and functional testing.

The manufacturer found that the molded parts met its stringent dimensional, mechanical and aesthetic specifications. The total time to produce the prototype tool, including the time to print the inserts, was only 4 weeks, a reduction of 66% compared to the normal 12-week lead time for such a prototype tool. The cost of the tool from the moldmaker was $21,000, a $42,000 savings compared to a quote for a conventionally made tool.

Read about how Mantle’s TrueShape technology enabled new medical mold applications, or this case study with Westminster Tool.

Related Content

-

The Connector Conundrum: 3D Printed Mold Tooling’s Role in Innovation

ReelView Fishing faced an electronics obstacle in the development of its new technology for underwater video. Additive manufacturing for moldmaking enabled the speed necessary to iterate to a solution.

-

5 Trends in 3D Printed Injection Mold Tooling

3D printing has moved beyond conformal cooling, and is now being applied to injection molds more broadly. Observations on additively manufactured mold tooling from the Plastics Technology Expo — PTXPO 2025.

-

2024 Moldmaking Insights: A Year in Review Part 2

A look back at the top moldmaking trends of 2024, as revealed through MMT's analytics. This review highlights the most popular technical articles, case studies, tips and best practices that captured the industry's attention over the past year.