Tradeshow Tuesday: Targeting Moldmakers in Product Descriptions

Being mindful of the audience that will read a product and adding language to it that illustrates the product’s relevance to that audience will help a product achieve maximum visibility and persuasiveness.

Moving into the second week of January, I cannot stress enough that it is not too early to begin planning for NPE, Amerimold and IMTS. Preparation is the key to taking full advantage of the many opportunities ahead. While its still early in the year, I thought I would put out a blog post on product submissions for tradeshows. For this post, I’d like to address all moldmakers and technology suppliers. My thoughts here are for those of you who contribute material to MMT’s product section.

As the managing editor for MMT, I oversee products and news for the brand. Something I’ve noticed in editing this material is how infrequently product submissions include clear language that explains why a moldmaker (and not just any machinist or metalworking professional) would consider investing in the product.

Sounds odd, right? I’m not saying that it doesn’t happen. Submission material occasionally includes such a description, and some products, because of what they are, clearly demonstrate their value to a mold shop. Other product submissions include a few words here and there about moldmaking applications (or may just include the word “mold” somewhere in the text), but a fair portion of them have no language in them that help the reader understand why a given item is suitable for the moldmaking niche of the metalworking world.

So, why does that happen? My guess is that for many groups, the same spot of PR is sent to a variety of places. As the essential specs of a product don’t generally change across the venues where a product description might appear, companies use the same material for a variety of outlets, which streamlines the writing and boosting efficiency and process simplicity. In major show years, groups planning to show the same thing at each show may use one description for all three shows for the same reason.

This is a critical misstep! It is a wasted opportunity not adding a few words to a product description that speak directly to the moldmaker reading your product in MMT. Just because a product has applications in a variety of industries does not mean that companies should use the same language in their efforts to appeal to all the prospective buyers in those industries. Matching the value of a product to the needs of a specific industry makes it easier for members in that industry to perceive the product’s value.

Matching the value of a product to the needs of a specific industry makes it easier for members in that industry to perceive the product’s value.

Making a little bit of effort to include language that targets moldmakers will demonstrate that you understand their profession, that you understand their products-related needs and that you are invested in providing effective solutions to those needs.This will give you credibility. An inch of extra text on paper could boost your bottom line by miles.

Why am I suggesting this targeted approach in crafting your product material? MoldMaking Technology wants to distribute niche-industry specific content that is targeted to moldmakers, and I want to help your material do the best that it can to reach prospective buyers.

Now, as you assemble products for the upcoming shows, consider adding one or two sentences that highlight how the product is appropriate for moldmakers. It is absolutely worth the effort.

As you assemble products for the upcoming shows, consider adding one or two sentences that highlight how the product is appropriate for moldmakers.

If you have any questions about product submissions at tradeshows or about the products section in the print magazine or online, you can reach out to me at kcornelissen@moldmakingtechnology.com

Related Content

Making the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read MoreFor PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

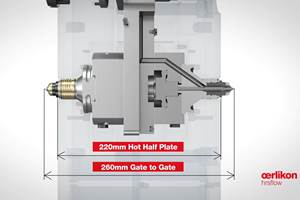

Read MoreStack Mold System Combines Fast Injection With High Process Repeatability

NPE2024: Primarily designed for thin-wall packaging applications, the patent-pending mold design by Oerlikon HRSflow brings consistency, simplified maintenance and assembly and a sustainable materials focus.

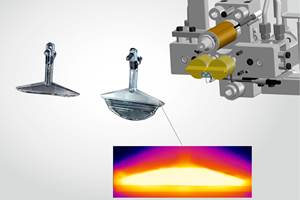

Read MoreLocalized Mold Temperature Control Reduces Knit Lines, Optimizes Melt Flow

NPE2024: Dynamic localized mold temperature control Heat-Inject Technology by Incoe Corp. demonstrates how the part surface quality and the filling of the cavity is optimized with relatively little effort using targeted heat pulses.

Read MoreRead Next

Tradeshow Tuesday: a New Blog for a New Year

2018 has finally arrived. One new thing for MoldMaking Technology is a new topic for the Tuesday blog. Through August 2018, some of the Tuesday blogs will cover issues related to tradeshows.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More

.jpg;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)