How to Ensure Quality Offshore Tooling

When working with a foreign mold builder provide clear expectations and conduct comprehensive reviews throughout the moldmaking process to ensure a robust mold.

When there are many miles between you and your mold builder, consider the following five approaches to ensure the mold is built on time, on budget and at the quality the project deserves.

- Present clear mold expectations. Provide thorough specifications as you’ll be working with a translator who will need to relay the requirements to the tool-building team. Well-defined instructions will help them do their job accurately from day one. Any ambiguity will necessitate clarifying questions that can start eroding the timeline because of the need to go back and forth via email. With at least a 12 hour difference between the United States and China, that can amount to a lot of lost time over small details.

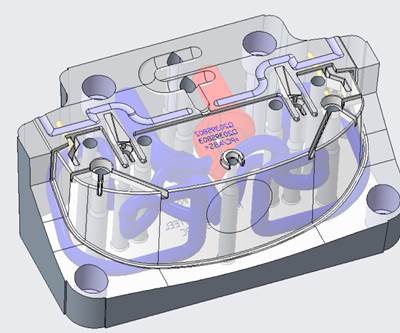

- Have experienced mold engineers on your team. The mold builder will provide the proposed tool design to the tool engineer for review, which is usually located in the U.S. If that person doesn’t understand critical mold components, such as the overall mold flow, the proper amount of cooling and the gate location, the ramifications to the mold (or part) downstream can be substantial. A qualified engineer needs to be able to review the design, mark the problem areas and send the design back to China for a second pass to ensure the tool is robust. Included in this review should be a thorough audit of the proposed mold material.

- Stay on top of timeline check-ins. As key milestones arise, review the updates thoroughly and ask questions if something doesn’t seem right. Working with a team abroad means you’re relying on emails, software renderings and pictures for those checkpoints. For example, during a review of the completed mold, make sure you’re getting images across a range of angles and lighting to ensure you can conduct an accurate assessment and provide specific, actionable feedback. Flagging miscues as you go makes it easier to fix them before the build gets too far along.

- Prepare for first-run samples. Be very clear as to what the expectation is for the first sample, including the number of required parts and the dimensional inspections for review. To help conduct a thorough analysis of the first run, ask for the moldmaker’s record of the molding process and equipment. And, request a video that shows the parts ejecting from the mold and the total molding cycle. Without appropriate documentation, both written and visual, it can be easy to misrepresent cycle times or the quality of the parts.

- Understand measurement methods for part qualification. To ensure you understand how the moldmaker is conducting its measurements, ask to have their CMM measurement methods, including pictures of the part setup and the programs. These items will allow you to compare their methodology and confirm the parts are meeting standards. If the part is misaligned, measurement results are most likely incorrect, which will lead to incorrect decisions on mold adjustments.

A well-made part starts with a well-made tool. For a myriad of reasons, shops are working with foreign makers. The best ways to help ensure a robust mold are to provide clear expectations and conduct comprehensive reviews throughout the moldmaking process.

About the Author

Jim Sensenbrenner is Corporate Tooling Manager for Evco Plastics.

Related Content

Maintaining a Wire EDM Machine

To achieve the ultimate capability and level of productivity from your wire EDM on a consistent, repeatable and reliable basis, regular maintenance is a required task.

Read MoreThe Benefits of Hand Scraping

Accuracy and flatness are two benefits of hand scraping that help improve machine loop stiffness, workpiece surface finish and component geometry.

Read MoreHow to Eliminate Chatter

Here are techniques commonly used to combat chatter and guidelines to establish a foundation for optimizing the moldmaking process.

Read MoreLaser Welding Versus Micro Welding

The latest battle in finely detailed restoration/repair of mold materials.

Read MoreRead Next

Conformal Cooling: Not Just Faster Parts but Better Parts

EVCO Plastics has been offering DMLS conformal-cooled inserts for years and like many shops today, they outsource this work to mold builders who have expertise in DMLS.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More

.png;maxWidth=300;quality=90)