Twenty Years of Copper Alloys in Moldmaking

A look at where we are today with the integration of copper alloys in mold building.

Prior to 1987, there was very limited use of copper alloys as molding surfaces and molds using copper alloy materials were rare. It was believed by a majority at that time that copper alloys were just not strong enough, hard enough or tough enough to endure in a mold.

In 1988 there was an article published, whose first sentence read, “Every injection and blow molder who intends to stay in business must continually ask himself, ‘What must I do to run as fast and efficiently as possible and still meet the customers’ quality requirements?’” From that point, the article went on to cite the how’s and why’s for using copper alloys in mold applications and how copper alloys would contribute to mold cycle reductions and part quality improvements.

Fast forward 19 years and ask the following:

Q. How many of the molders and moldmakers—who did or did not follow that insightful and educational information—are still in business today?

A. Statistically about 50 percent of molders and moldmakers have embraced the technology and it is believed that the holdouts who chose not to have paid the price. Some are gone from the industry completely, some have lost business and others are still out there, but struggling.

Q. Are molders and moldmakers using copper alloys effectively and efficiently in their molds?

A. In most applications the usage is still quite conservative and in many cases the copper alloy that does get used, may be the wrong alloy for the specific application. The decision to use the wrong copper alloy may be driven by misinformation about specific alloy performance, product misrepresentation, pricing or availability issues. This will lead to less than optimum performance, short component life or outright failure.

Q. Are the best products for the mold application being used or is the techno-logy being obstructed by ignorance, supplier sales pitch or misinformation?

| Table 1 | |||

| CDA # |

Hardness | Elongation | Conductivity |

| C17510 | 20 R/C | 5-15% | 145 |

| C17200 | 30 R/C | 3-8% | 75 |

| C17200 | 40 R/C | 1-3% | 60 |

| C18000 | 20 R/C | 9-13% | 150 |

| none | 28-30 R/C | 7% | 80-90 |

| C72700 | 30 R/C | 4% | 35-40 |

| C72900 | 34 R/C Min | 3-5% | 22 |

| C95400 | 89 R/B | 12-14% | 36 |

| C95900 | 30 R/C | 1.5% | 25 |

| none | 29-32 R/C | 1% | 25 |

| Hardness, elongation and conductivity. Table courtesy of Manufacturer’s Product Literature. | |||

A. There are misapplications of copper alloys all of the time. Many times the wrong copper alloy is used because of ignorance, misinformation or misrepresentations by suppliers. What may seem as an insignificant change from one product designation or brand to another can significantly impact the mold component life and performance. For example, copper alloys with similar hardness levels can have conductivity levels (the main reason for using copper alloys) only slightly higher than steel. Another example: copper alloys with hardness levels approaching 40 Rockwell “C” have very low ductility with elongations in ranges less than 3 percent. Low ductility and elongation often leads to cracking or breakage of mold components (see Table 1).

Copper Alloy Usage

During the last 20 years, copper alloy use as molding and wear surfaces in molds has been expanding although the industry has been slow in learning how to properly and fully integrate copper alloy products into their mold designs. The growth of copper alloy use in comparison to technological advancements with machinery, process equipment and resins has been limited by market acceptance, and in some cases, lack of understanding the available products.

An informal survey of molders and moldmakers still shows a large percentage believing that copper alloy usage in their molds is of little to no benefit. The belief is that copper alloys will not really reduce their mold cycles, will not improve part quality or will not contribute to other performance improvements. There also is fear of higher maintenance costs or higher initial mold costs.

Experience by molders has shown copper alloys actually do reduce mold cycle times, improve piece part quality and reduce mold maintenance costs. Moldmakers or molders that increase prices because of copper alloy usage are often just inexperienced with the product or just taking advantage of the situation. Typically copper alloy mold components show cost savings to the mold builder due to machining processes for those copper alloys that offset the additional cost of copper alloys over tool steels.

Beryllium Copper or Copper Nickel Alloys

Basically there are two families of alloy chemistries that yield high strength, high conductivity alloys that are the best choices for use as molding surfaces in molds. The families are either beryllium copper-based, or copper nickel-based. Both alloy families have other minor elements added for individualized purposes in each combination.

Even producers of beryllium copper alloys have been offering copper alloys without beryllium due to competition and continuing issues associated with beryllium-containing alloys. In some cases, manufacturers have created alloy designations or names that detract from the acknowledgement of beryllium content (see Table 2).

Industry Challenges and Strategies

Global Competition

Like it or not, we are all working, competing, buying and selling in a global market, and remarks made by industry regarding the unfair competition from countries with lower labor costs, favorable monetary exchange rates, tax benefits or other motivating factors are common. However, this is nothing new and has still yet to run its course. In the 60s and 70s it was Japan, in the 80s it was Taiwan and Hong Kong, then Singapore and Korea, and now it’s China.

| Table 2 | ||||

| CDA # |

Cu | Be | Ni | Alum |

| C17510 | Balance | .2-.6% | 1.4-2.2% | none |

| C17200 | Balance | 1.8-2% | none | none |

| C17200 | Balance | 1.8-2% | none | none |

| C18000 | Balance | none | 1.8-3% | none |

| none | Balance | none | 6-7% | none |

| C72700 | Balance | none | 8.5% | none |

| C72900 | Balance | none | 15% | none |

| C95400 | 83%min | none | 1.5% | 10-11.5% |

| C95900 | Balance | none | .5% | 12-13.5% |

| none | Balance | none | 2% | 13% |

| Alloy designations. Table courtesy of CDA Bulletin 1433-8929. | ||||

Guess what? When the luster is gone from China as a source, then there will be some other county or region that joins in—countries such as Africa, India, Vietnam, Cambodia, Indonesia, even the Persian Gulf area, just to name a few.

Supply Chain Loyalty

Another common remark involves business dealings with the supply chains today and the lack of loyalty to companies that truly add value to the process. This would seem to be counterproductive to long-term success and can be a developing problem for companies in all facets of the supply chain with downstream consequences. It is extremely important to seek out and develop relationships with companies that add value and work to drive out unnecessary costs, not just one time, but with loyalty on a continuous basis.

A simple checklist or grading system is helpful in determining primary suppliers in your supply chain. The checklist should use a 5 (Best) to 1 (Worst) qualification process. This checklist should be maintained as the suppliers’ ongoing report card.

- Maintains product inventory usable to your needs

- Provides technical support for all phases of mold design and manufacturing

- Experience in manufacturing the products and troubleshooting in applications

- Well established in business

- Regarded by industry as having high integrity

- Quick response on quote requests and order processing

Adding value and driving out costs are accomplished by establishing relationships with suppliers that contribute the absolute latest in technical support along with the best product knowledge and experience in the marketplace. Many times this can only be accomplished through ongoing loyal business dealings that build trust. If customers buy from different suppliers every time or a purchase is based purely on price, neither the seller nor the purchaser has a real chance at long-term success.

Resistance to Change

Resistance to change has been—and still is—an uphill battle for many companies, especially when mold shops are seeking to make improvements in mold performance. Even the most successful molder or moldmaker with what they believe is the latest/greatest design is plagued by what appears to be this relentless issue. That resistance to accept ideas and technologies from outside or third-party sources has and does limit the potential for companies in the entire supply chain.

All too often molds are designed and built just “good enough to work” rather than designed and built with the very best design concepts, materials and components. In many cases, this resistance to change sets in motion an eventual bankruptcy, foreclosure or situations where an owner will just decide to downsize or close the doors entirely.

What is left for those of us still in business in this industry? Without a doubt a new attitude is needed followed with the sentiment for continued improvement and change. This industry must develop a survival of the fittest mentality—becoming truly “fit to serve the market”. This means we must develop a business attitude, which yields a company motivated to participate in ongoing change and continued development. This does not mean just change once or change just a little, then slow or stop.

The Copper Alloy Solution

So where are we today with the integration of copper alloys in mold building? There are still major opportunities and major contributions to be gained by companies that are willing to use these products.

One example is there must be greater importance placed on water flow rates and controlling, such in molds when using copper alloys. To maximize the benefits of copper alloys the design of water flow should be to maintain “turbulent flow” versus “laminar flow”.

Turbulent flow maximizes the heat removal process. This turbulent versus laminar flow was not a significant issue due to the low BTU removal rate of tool steel. This without a doubt seems to be something that has long been overlooked by many in the industry because of the attitude, “It’s just a water line.”

If you do not believe this statement, ask any moldmaker how close they hold water line diameters/depths and whether turbulent flow calculations are used in determining watering systems. It is doubtful that any of them will acknowledge the need, because you will get the answer “it is just a water line”. Well readers, it is not just a water line anymore.

Another example for improving mold performance with copper alloy is cited in the October 2007 issue of MoldMaking Technology that references using bronze or aluminum bronze for the base material in making ejector sleeves for molds. These components when made using bronze material far outlast any tool steel sleeve and the problems, downtime and maintenance that results because of the tool steel will be a thing of the past.

In the last 10 years, cycle times for successful molders have been cut nearly in half and there is still opportunity to run faster through the use of copper alloys. The technology of copper alloys as molding surfaces combined with controlled water flow and with all of the experience gained in the last 20 years will produce success in meeting the faster cycle requirements. If you are dealing with a material supplier that only “parrots” the history of their products in applications, you need to get hooked up with suppliers that can help with facts that lead to improvement in the designs that you have on the board today.

The question today is, “Is there still room to make improvements in mold designs and mold cycles? The answer is “Yes!” The opportunities are endless, and mold capabilities where the cool time is less than the mold fill time are possible.

Work with sources/suppliers that have a niche in their respective market, a true history of expertise in their discipline, willingness to openly provide improvements without reservation and a drive to maintain a successful business model in their own operations.

History has shown for most that cheap molds run and perform like cheap molds. For companies that are into buying cheap molds it may take some time for their true cost to surface. This is due to the real cost of a cheap mold never being exposed through the ranks of a company because the expense to get it running (productionized) is part of some departmental budgeting process that is not part of the initial mold cost, is not clearly visible, or is masked by the personnel involved in the mold procurement process. Remember, success does not come without a price tag and equally important is having the right people and right suppliers involved.

Related Content

Aluminum Machining Efficiency Improved With Milling Inserts

The TungAluMill line has been enhanced with 10 new XVCT-AM inserts, featuring an interface design that augments machining at high speed rates.

Read MoreAluminum Plate for High-Temperature Tooling Applications

NPE2024: Ellwood Specialty Metals exhibits its EllCast 2 aluminium plate. Its strength at high temperatures, combined with high thermal fatigue resistance and hardness, makes EllCast 2 ideal for critical applications.

Read MoreHow is an Aluminum Mold Energy-Efficient?

Nine ways aluminum molds save energy and production costs.

Read MoreCoated Grade Inserts for Machining Aluminum Alloys

The WXN15-coated grade inserts introduced by Walter USA can be used for copy milling, face milling, ramping, pocket milling and circular interpolation milling.

Read MoreRead Next

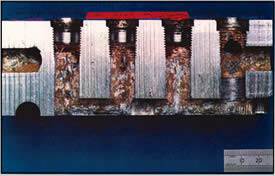

Facing Your Corrosion Challenges to Avoid Mold Failure

Analyzing corrosion in aluminum blow molds and how to prevent it.

Read MoreCost Savings for Mold Materials: Consider the Details

Ways to reduce costs that are not related to the price per pound of the mold material.

Read MoreDesign Criteria for Using Copper Alloys in Molds

The extent of copper alloy use, the success of its application and the life of the components are determined by the selected alloy in combination with the design of the application.

Read More

.png;maxWidth=300;quality=90)

_300x250 1.png;maxWidth=300;quality=90)