Process Cooling Boosts Mold Efficiency

Mold builders can optimize mold performance by taking advantage of advanced process cooling technology.

Whether it’s for a precision mold with a relatively low production volume or a straightforward mold designed specifically for a high production run, the importance of incorporating process cooling continues to increase for mold builders.

The reason is clear: Process cooling and its associated data points, including flow, pressure and temperature, play an essential role in optimizing mold efficiency, which translates to reduced cycle times. To be competitive, mold builders must optimize a mold for efficiency, record the data used to achieve this efficiency and share the data with molders so they can achieve the same results.

Fortunately, advanced process cooling technology is available in the form of a closed-loop fluid cooler and a combination chiller/temperature control unit (TCU) at each machine. Such an integrated system can help moldmakers more readily optimize a mold for efficiency. More specifically, the system provides greater flexibility in temperature control compared with a conventional central process cooling system. It also provides constant water pressure and flow to the cooling process. The end result is the ability to optimize a tool for maximum results. Additionally, by recording all pertinent data on a process sheet, moldmakers can relay critical information to molders.

Cooling Basics

Process cooling typically consumes 60 to 70 percent of a molding cycle. Simply put, nothing else is happening in the molding process while the mold cools. The ability to reduce the amount of required cooling time therefore translates to an exponential decrease in cycle time, which means improved production for the molder and better profit margins.

What it boils down to for the molder is the need to maintain product quality from cycle to cycle and even cavity to cavity while still meeting production goals. Validation is mandatory in industries that require critical parts, such as those used in medical, aerospace and other applications. However, validation perhaps is equally important even in less-critical applications—bottle caps, for example,—since the ability to save just pennies on millions of parts still results in substantial gains in profitability.

In a nutshell, the function of a process cooling system is to remove the heat from the mold. Key process cooling parameters include cooling system capacity, coolant pressure and coolant temperature. These factors help determine the optimal operating point for each mold because they dictate the efficiency of the heat transfer and, therefore, optimal cycle time.

Moldmakers should tell their customers what parameters were used to achieve tool quality in a specified cycle time. Specific data should include capacity used for mold validation, coolant type (water or water/glycol mixture), coolant supply pressure to the mold, flow rate from the cooling system and individual flows for each mold circuit, temperature of the coolant supply to the tool, and temperature differential across the tool and each individual cooling circuit. The lower the temperature differential across the tool, the more efficient the tool, as this number signifies high flow and turbulence.

Of course, if the customer does not follow the mold builder’s recommendations, this molder may not achieve the same results.

Cooling Approaches

As mentioned earlier, there are multiple approaches the moldmaker can use to supply process cooling to molds. Traditional methods typically involve a central process cooling configuration that takes the form of either an open cooling tower, or air- or water-cooled central chillers. These methods often fall short in identifying and validating the characteristics needed to optimize the mold for peak efficiency, however. They also can stand in the way of profitability.

An open cooling tower provides cooling water directly to both the machine and the mold. The cooling tower extracts heat by allowing a small portion of the water to evaporate into a moving air stream to provide significant cooling to the rest of that water stream. If the cooling tower is used as the central system, however, it can’t effectively control the temperature of the process cooling water, because it cannot provide water below the ambient wet bulb temperature it is capable of producing. In other words, the more humid the atmosphere, the lower the capacity of the cooling tower.

Another challenge related to evaporative cooling towers is poor water quality, which results in contamination and scaling inside the mold cooling channels. Scaling reduces the efficiency of heat transfer, since scale buildup acts as an insulator and prevents the water from “scrubbing” the heat from the tool. Therefore, frequent mechanical removal of the scale is required.

An open-air system also creates the risk of waterborne illnesses such as Legionella, since the stagnant water typically present in the basin of a cooling tower provides ideal conditions for the growth of bio-organisms, and the potential for contaminated water

vapor or droplets to be introduced to surroundings.

To avoid problems associated with dirty water, some moldmakers install air-cooled chillers to cool molds and machines. Air-cooled chillers use ambient air to remove heat through a refrigerant circuit, similar to a household air conditioner that removes heat from the air and dissipates it outside the house. However, because such air-cooled chillers rely on ambient air to remove the process heat, this setup is costly. The higher the ambient air temperature, the higher the compressor condensing temperature and therefore the lower this compressor’s efficiency and the more electrical energy required to provide the chilled water.

The air-cooled chiller setup also adds complexity, as some operations might call for higher temperatures than an air-cooled chiller can provide. This increased cooling temperature would be determined by the mold design and desired cycle times. In such cases, a TCU is needed to increase the cooling temperature and therefore optimize the tool. The need to heat water that was previously cooled also adds operational costs in the form of energy consumption.

In addition to compensating for proper temperatures, moldmakers and molders alike also must address the reality that water pressure (and therefore flow) will rise and fall as the numbers of machines being cooled go on and offline, no matter what type of traditional central process cooling configuration is used. Fluctuations in pressure and flow in process cooling are similar to the same fluctuations that occur when water is used in a residential home.

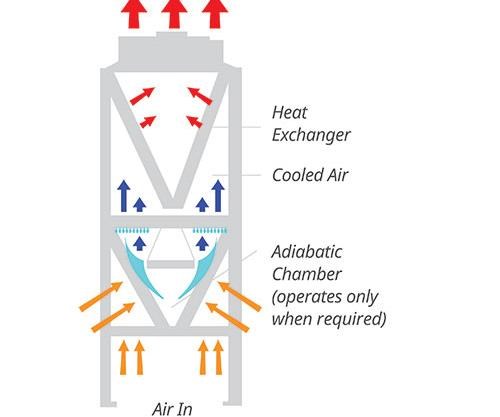

An increasing number of mold builders are now turning to integrated, closed-loop process cooling systems that incorporate central fluid coolers and a combined chiller/TCU at each machine. One such integrated system uses a closed-loop fluid cooler with a pre-cooling chamber to cool water circulated from the molding machines. This system’s process is as follows:

1. In the pre-cooling chamber, a fine mist of water is pulsed into the incoming air stream in high ambient temperature conditions.

2. The mist evaporates instantly, cooling the air before it impinges on the cooling coils that carry the process water.

3. The process drops the temperature at or below the setpoint. Cooled water is then re-circulated to the facility’s molding machines.

4. A microprocessor-based controller automatically maintains targeted cooling temperatures.

This closed-loop system, eliminates the problems associated with dirty water, and it uses less water and energy than a traditional configuration, because it takes the cooling tower and the air-cooled chiller out of the equation.

The closed-loop fluid cooler and combined chiller/TCU also offers simplicity and cost savings versus a cooling tower/central chiller/TCU configuration, given that fewer pieces of equipment are required. Less water and energy consumption also translates to savings over the life of the system. Additionally, maintenance costs associated with cooling towers are eliminated, on top of the reduced costs associated with chemically treating the system.

Key to the integrated system are machine-side combination chiller/TCUs, which include packaged water-cooled refrigeration systems and, depending on the machine, either one or two TCU circuits housed inside a compact cabinet. A solution like this provides flexibility, because each chiller/TCU is dedicated to its own molding press and operates independently from the other units. It isolates the mold from the rest of the facility, and a high-flow process pump feeding water to each machine ensures consistent supply pressure, temperature and delivery of high turbulent flow throughout the mold.

The combined chiller/TCU also independently controls each mold half and accommodates precise heating and cooling requirements. Users can adjust each zone to readily achieve temperatures ranging from 48°F (for non-glycol systems) to 195°F. Additionally, combined chiller/TCUs with servo-proportioning, three-way temperature-control valves offer consistent and precise temperature control, which can yield an accurate temperature setting for a given mold and specific material. The valves tightly control the amount of cold water bleeding into the mold from the refrigeration circuit. In combination with tight control of the internal heaters, temperature can be smoothly fluctuated up and down within 0.5°F of the setpoint.

Another benefit of an integrated closed-loop system is “free cooling,” meaning the central fluid cooler provides water at the necessary temperature where needed without using chilled water, resulting in significant energy savings. Additionally, the unit automatically cycles off its compressor to satisfy the cooling load at the exact temperature requirement and delivers only the level of refrigeration needed. The clean water central cooler provides the rest of the load without the need for refrigeration. The need to power energy-intensive compressors used on chillers is significantly reduced, providing cost savings.

To remain competitive, mold builders must focus on ways they can speed cycle times, from mold design to declamping/open/eject rates and everything in between. Those who pay extra attention to process cooling options will find they can add value for their customers and improve profitability at the same time.

Frigel North America, Inc.

Related Content

Exploring ISO 9000 - Part 16 Control of Quality Records

A Series of International Standards for Quality Management and Quality Assurance. We begin 2022 with a review of Clause 4.16 Control of Quality Records.

Read MoreLaser Welding Versus Micro Welding

The latest battle in finely detailed restoration/repair of mold materials.

Read MoreSurface Finish: Understanding Mold Surface Lingo

The correlation between the units of measure used to define mold surfaces is a commonly raised question. This article will lay these units of measure side by side in a conversion format so that companies can confidently understand with what they are dealing.

Read MoreConsiderations for Mold Base Material Selection

Choosing the right material can greatly affect the profitability and cost of your application.

Read MoreRead Next

How to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More

.jpg;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)

_300x250 4.png;maxWidth=300;quality=90)