This Fooke Endura five-axis machine is a critical machine tool in CDM Tool & Manufacturing’s technology arsenal for finishing molds. Photo Credit: CDM Tool & Manufacturing.

Can you explain CDM Tool’s growth challenge despite its long history in moldmaking?

Stephen Hansen, CEO & Owner, CDM Tool & Manufacturing: CDM Tool has a rich history of moldmaking in Wisconsin and the Midwest dating back to 1962. CDM was historically known as a team that would tackle large, complicated and challenging molds for its customers in presses from 700 tons up to 6,600 tons within its Hartford, Wisconsin, 40,000-square-foot facility.

However, in the early 2010s, CDM underinvested in its facilities, equipment, tooling and people. More importantly, the untimely death of its owner, together with the retirement of two key leaders, created a vacuum of valuable knowledge. As a result, although its workforce continued to produce high-quality molds, CDM struggled to strategically differentiate itself from the competition and grow its sales.

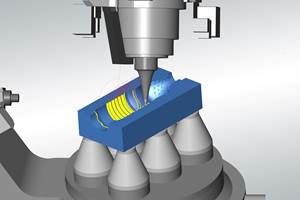

This Fooke Endura 704 linear five-axis machine has a compact gantry design with linear motor drive technology and five CNC-controlled simultaneous axes (86 x 138 x 59 inches, 60,000-pound capacity and 24,000 rpm).

How did CDM begin to tackle this challenge from the technology perspective?

Hansen: In 2015, a family investment ownership group purchased CDM. Their philosophy is to buy small manufacturing companies and then invest in developing both the business and the people for long-term growth and value creation.

On the technology side, the new owners purchased a new Toshiba CNC to upgrade CDM’s bar machining, a new Fooke five-axis high-speed mill to provide additional high-speed, accurate finishing and a new overhead crane system to handle up to 30 tons.

We continue to make heavy capital investments in tooling replacements and upgrades as well as existing machine maintenance. For example, in 2020 and early 2021, we invested $75,000 in new tooling with the latest in cutter and holder technology and plan to invest heavily again in 2022. We also invested more than $200,000 in large CNC and EDM machines, updated control technology and replaced worn parts.

We also reconfigured the plant layout in 2017 for optimal machining center efficiency. We grouped small machines away from the larger machines to create focused leadership and improve the overall performance of each machine type. Most of our workforce is cross-trained in their small or large machine area, providing operating flexibility when needed.

What about renewed investments in the people side of the business?

John Farrelly, President, CDM Tool & Manufacturing: We made investments in leadership training for all department heads, supervisors and managers to provide a framework for supporting our core values and fundamental behaviors. The training focused on leadership techniques and methods to bring performance in line with our high-quality standards.

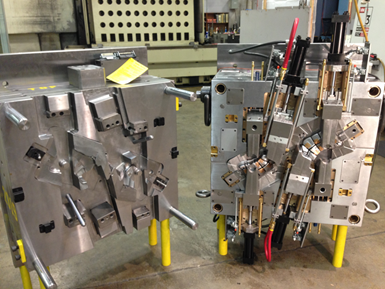

CDM Tool’s design team works with customers to develop the right mold solution, taking CAD files, blueprints or specifications and creating a fully fleshed out mold design that will perform to customer standards.

Our core values and fundamental behaviors are centered on two key principles: (1) we exist to provide our customers with the highest quality workmanship delivered on time and (2) we expect everyone to work together collaboratively and respectfully while enjoying our work and each other’s company.

The new ownership also introduced an open, collaborative and humble management style. The change started with communicating and explaining the behavior we expected, acknowledging that we’re all on a constant journey of improvement. We discuss one of the behaviors every week during our meetings to reinforce the concepts, allowing each employee to present their thoughts on that week’s highlighted behavior.

I learned a long time ago that our shopfloor workforce has all the answers; they just need to be asked the right questions.

Employee views and opinions are now valued and sought after when making business decisions. For example, our machinists and toolmakers are integral to the mold design process. They are in all design review meetings and are asked for input on mold design and functionality. We also ask the machinists for their feedback on new machine decisions and specifications. I learned a long time ago that our shopfloor workforce has all the answers; they just need to be asked the right questions.

In addition, we established a renewed focus on safety, quality, delivery and cost—in that order. This order of priority—safety is first, quality is second, on-time delivery is third and cost/profits are fourth—is critical to our mission of customer satisfaction and long-term success. We discuss our weekly and year-to-date performance during our weekly meetings and welcome and encourage all opinions and ideas on ways to improve these.

From this leadership style change, we now have a new culture that values open, candid communication and problem-solving by each employee. We celebrate wins, such as a “good month’s results” with informal after-work parties and a sincere “thank you” when deserved.

We also learn from losses by breaking down what went wrong, why and how to correct the process to minimize future losses. Formally, we post-audit our performance on most new mold builds, examining the actual versus planned performance variances for learning where mistakes occurred.

Last but not least, we emphasize taking personal responsibility for the work performed by asking each person to “sign their work with the pride that comes from A1 best quality work.” That is straight from my father.

CDM Tool boasts a dedication to precision—tolerances as tight as 6/10,000ths over a 140-inch span and 14/10,000ths over 23-foot span.

Can you give an example of this open communication?

Farrelly: Our new handbook states simply, “We hire adults, we expect employees to act like adults and we are committed to treating employees like adults.” Responsibilities and expectations are clearly articulated and understood. Adults will understand the importance of candidly sharing vital information.

CDM Tool produces finished tooling from small and simple to large and complex, claiming significantly larger than its competition.

Hansen: For example, CDM’s design process is a thorough analysis of how the mold will work in the customer’s press back to manufacturing and assembling the mold’s parts. In this process, we include input from the entire team assigned to a new mold build, which promotes early and frequent collaborative interaction between the toolmaker, the machinists and the design team. This results in designing the best mold for our customers manufactured efficiently and at the highest quality. The team truly owns the responsibility for the mold’s performance in the customer’s press.

Farrelly: We also share our monthly and year-to-date financial results at our weekly meetings. Any person can ask leadership any question on the business, how we’re doing and how we see the business performance in the future. We are committed to giving honest answers to all questions.

Decades of plastic injection mold manufacturing give CDM Tool the ability to produce molds for 50 to 6,600-ton presses, up to eight cavity molds, Class 101 to Class 105, high-pressure, structural foam, double-shot (two-shot) molding, thermoset and overmolding as well as in-house tool welding.

What has been a noticeable benefit from this new open communication and collaboration?

Hansen: As a result of this engaged team collaboration, CDM has become a recruiting machine that brings on new talent needed for growth. Some recent new hires sought out CDM because of the reputation of the culture and the investments made by the new owners. In addition, we have solid relationships with two local high schools with strong technical trade education programs. We regularly attend student career events and sponsor interns and apprenticeship programs.

Currently, we have two registered toolmaker apprentices and a youth apprentice machinist who will soon enter a machinist apprenticeship. We intend to hire more students this school year.

Can you share a specific example of your team’s impact on a customer project?

Hansen: One recent example of the CDM team working together to solve challenges and deliver wins for its customers comes from the reshoring initiative that key customer mDesign is undergoing. mDesign has historically sourced molds and plastic products from China, but with shipping costs increasing for their plastic parts, mDesign began looking for alternative options. mDesign found a partner in CDM who can deliver molds designed and manufactured with high quality at a reasonable price.

Pre-production planning is critical to CDMTool’s service. The level of quality the team expects from itself requires a joint effort between designers, moldmakers, machinists and management.

By partnering with CDM, mDesign has chosen a high-quality mold builder who has the experience and expertise to overcome the challenging environments in which their molds operate. From sales through design and manufacturing, mDesign knows they are working with a quality team that cares about their success and will be there to support them at a moment’s notice.

Last but not least, we emphasize taking personal responsibility for the work performed by asking each person to “sign their work with the pride that comes from A1 best quality work.” That is straight from my father.

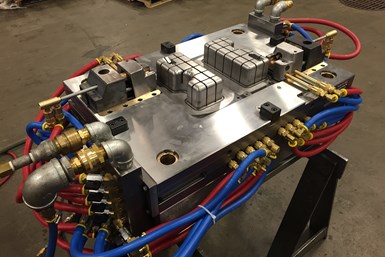

An example of the optimized manufacturing strategies employed by CDM, this FPT Pragma 3+2 horizontal machining center was set up and programmed to machine three individual mold plates.

Once the mold is designed, our machinists continue to challenge themselves and our machine capabilities to find more cost-effective machining methods without sacrificing quality, which often leads to quicker mold builds. This helps us compete against overseas mold builders who have extended lead times and ever-increasing costs.

CDM’s creative approach to manufacturing is exhibited in a recent project for mDesign in which CDM used its large machines to machine three blocks at once for mDesign molds. This approach from the CDM team enabled lights-out machining that benefits CDM and mDesign.

Related Content

Moldmakers Deserve a Total Production Solution

Stability, spindle speed and software are essential consideration for your moldmaking machine tool.

Read MoreMachining Center Spindles: What You Need to Know

Why and how to research spindle technology before purchasing a machining center.

Read MoreDesign Strategy Tackles Big and Small Complexity Challenges for Southeastern Mold Builder

Delta Mold Inc.’s core values, engineering expertise, five-axis machines and molding capabilities help the team turn a proposal into a manufactured mold or part with custom design, finishing and assembly.

Read MoreCustomized CAM Strategies Improve Five-Axis Blow Mold Machining

The proper machining process and workflow can impact blow mold production, making your CAM software selection critical.

Read MoreRead Next

MMT Chats: COVID, Communication and Customers with CDM Tool & Mfg

CDM Tool & Manufacturing expedited and maximized resources with supplier support to be part of a solution in the fight against the coronavirus.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More

.jpg;maxWidth=300;quality=90)

_300x250 3.png;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)