Share

The MoldMaking Technology team has compiled this list of our top-performing content based on the analytics for items published recently. Check out these great pieces.

Check out the most popular items from this past month.

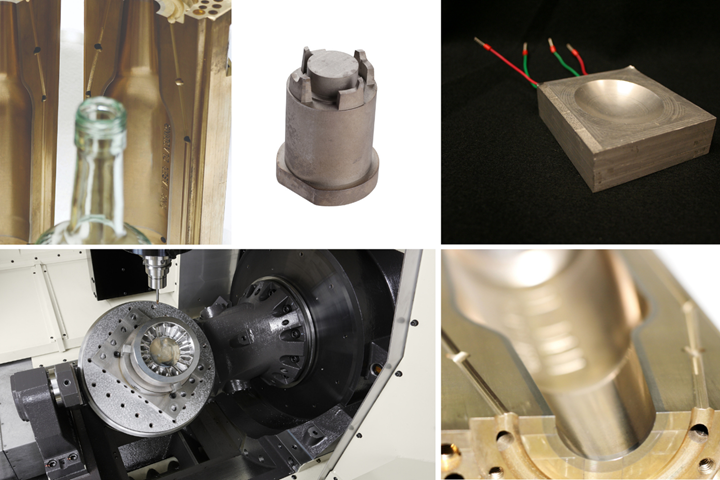

Three Good Reasons to Switch from Three- to Five-Axis Machining in Moldmaking

Five-axis machining technology is a great tool in the moldmaker toolbox.

Have You Heard of Printing Mold Inserts with Metal Paste?

A lower-cost 3D printing approach extrudes a metal paste to produce a mold insert with the required surface finish and tolerances.

How to Apply Ultrasonic AM to Moldmaking

An ultrasonic welding system brings a unique hybrid additive and subtractive process to moldmaking.

Use Hybrid AM to Produce Longer-Lasting Multi-Material Molds

A flexible, laser-based hybrid CNC machine makes it practical to produce high-performance molds and dies made from multiple metals.

Step 1 of Your Maintenance 4.0 Documentation Strategy

This free on-demand workshop reviews 1 of the 5 critical components to continuous improvement—mold maintenance documentation—and shares a “test” to score your toolroom on its mold maintenance documentation strategy.

MoldMaking Technology is here to bring you what’s new and what works in moldmaking. Not subscribed to MoldMaking Technology Magazine? Get it in either your mailbox or inbox for free.

Thank you all for your constant support of MoldMaking Technology. We are so glad to have you as a part of our community.

Related Content

-

How Hybrid Tooling Accelerates Product Development, Sustainability for PepsiCo

The consumer products giant used to wait weeks and spend thousands on each iteration of a prototype blow mold. Now, new blow molds are available in days and cost just a few hundred dollars.

-

Variable Density-Coated Tool Steel for High-Wear Molds

A mold builder can have an abundance of venting and fully dense solid areas in steel by using variable density sintering to eliminate gas trap defects in high-wear molds.

-

MMT Chats: California Mold Builder Discusses the Difficulties with Silicone Molding and the Power of the Magic 8 Ball

MoldMaking Technology Editorial Director Christina Fuges sits down with M.R. Mold President and Owner, Rick Finnie, to discuss how he began his moldmaking career, M.R. Mold's LSR Education, and the struggles of working with silicone. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

.png;maxWidth=300;quality=90)