MMT Memories: Giving Back to the Trade

1998 marked more than one proud moment for this journalist and moldmaker’s daughter.

If there’s one thing I know has always been true about my father, it’s that he is passionate about moldmaking and being a moldmaker. He loves the challenge of it and providing customers with solutions that exceed expectations. I am a proud daughter, but I believe anyone who has ever worked with or for my dad would say he’s a good man, a dedicated mentor and very talented at what he does. A lifetime of observing him ply his trade has taught me so much, including how to be someone who gives at least as much as one receives.

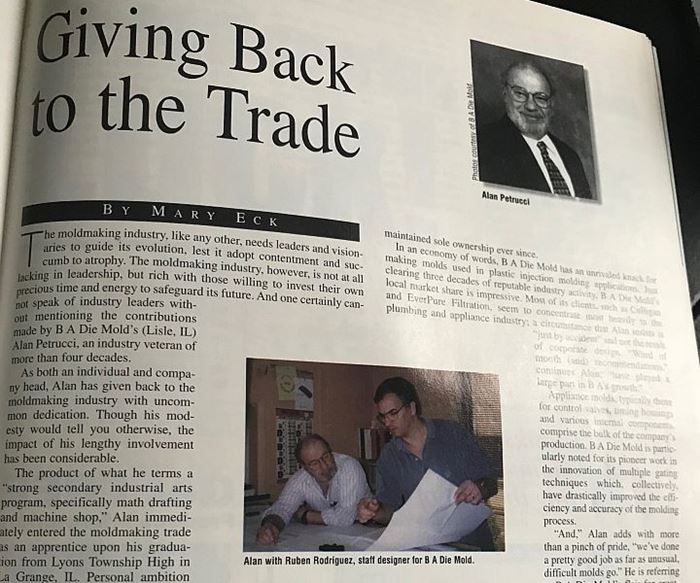

In 1998, when I discovered that MoldMaking Technology, the first and only magazine dedicated to our industry in North America, had been launched, I wanted people from all over to know about this moldmaker I called dad. In June 1998, a Who’s Who in Moldmaking feature titled “Giving Back to the Trade” was published. I was thrilled. My dad, Alan Petrucci, founder and CEO of B A Die Mold, Inc. beamed with pride.

“That article is still framed and hanging in our conference room,” he told me when I mentioned it to him and said I was going to blog about it because it was in one of the first issues of MMT, plus 1998 marked his company’s 30th year in business. I asked him what it means to have a magazine just for moldmaking. He replied, “Before MoldMaking Technology there was not another publication focused on moldmaking. The only information we got was from networking with other local shop owners or word of mouth. MMT was responsible for opening that up. It introduced mold shop owners to other mold shop owners across the country.”

Dad said that even when he and fellow mold shop owners in the Chicago area started the American Mold Builders Association (AMBA) in 1973, moldmakers were secretive about what they were doing, and kept anything considered a competitive advantage close to the vest. “No one ever really shared what they were doing,” he said. “I remember one mold shop owner, who shall remain nameless, even went so far as to talk down what was then the latest CAD/CAM software, Unigraphics, saying it was no good. He was lying to keep the competition at bay. Eventually we all realized the truth, and that he was using it quite effectively.

“Articles in MoldMaking Technology are informative and honest. It made a big difference for the industry,” he continued. “By and large, today most moldmakers are cooperating and working together, helping each other to compete with global competitors. That’s probably the most important part of the magazine because it features shops that are willing to share what’s successful and what isn’t in the way of equipment and processes and how they’re working to improve.”

Ever the advocate for getting more young people to discover career opportunities in moldmaking, my dad said to me, “It’s getting tougher and tougher for U.S. moldmakers to compete, and it’s not because we can’t compete, but because we don’t have the workforce. Without the support of skilled help, you can’t do the work necessary to compete globally.”

Now you understand where I get my passion for workforce development. My sister, Francine Petrucci, didn’t escape it either. She’s now president of B A Die Mold and is a tireless advocate of closing the skills gap as well. She, too, shared her thoughts about dad and MMT: “Having a moldmaker as a father is something I think a lot of the MMT readers can appreciate. They are great men with an eye for detail and an innate exacting nature that is unique to mold manufacturers, in my opinion. My dad also has an incredible work ethic that is something I am so glad to have grown up around. Over the years I have had many, many proud moments listening to other people in the industry tell me what working with or knowing my father has meant to them, their businesses, projects or careers. All very positive stuff!”

When I asked Francine what MMT has meant to her over the years, she said, “I just love MoldMaking Technology. I was always an avid reader of Modern Machine Shop and it’s still a great publication, but it was so darn cool when MMT hit the newsstands. Finally, a publication dedicated to our trade! We have different challenges than your average “production shop.” Plus, it’s been really interesting over the years reading about other mold manufacturers from across the country and learning about various machining solutions specific to moldmaking.”

I can’t close this blog without mentioning that this year marks the 50th anniversary of B A Die Mold, Inc. I feel rather proud that this special anniversary coincides with this publication’s 20th anniversary. B A was part of MMT’s “formative years,” and is one of the mold manufacturing companies that has spent the last 20 years with us. Now I am senior editor of MMT and able to continue working on behalf of an industry I grew up in and love, with the people I love. Happy 50th, dad and Francine. Happy 20th MMT.

![]()

Related Content

U.S. Economic Fundamentals Impacting Moldmaking

The economy continues to downshift, capping growth in moldmaking.

Read MoreVIDEO: What You Need to Know about the R&D Tax Credit Today

A team member from Strike Tax Advisory reviews the tax changes that are impacting the R&D credits for mold builders.

Read MoreR&D Tax Credit Refresher

A list of the top 10 moldmaking activities frequently performed through daily business that qualifies for an R&D tax credit.

Read MoreMMT Chats: Marketing’s Impact on Mold Manufacturing

Kelly Kasner, Director of Sales and Marketing for Michiana Global Mold (MGM) talks about the benefits her marketing and advertising, MGM’s China partnership and the next-generation skills gap. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

Read MoreRead Next

How to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More

_300x250 4.png;maxWidth=300;quality=90)

.jpg;maxWidth=970;quality=90)