Hygienic Ice Cream Cones, Thanks to CAM Software

CAM software ensures that ice cream vendors have an added degree of hygiene by allowing for the manufacture of a product that ensures the ice cream vendor doesn’t have to touch the waffle cone.

VISI CAM software ensures that ice cream vendors have an added degree of hygiene. In a truly international case, three Czech Republic companies worked together with UK software VISI to produce hygienic holders for ice cream cones in Germany. VISI collaborated with ABB Czech and SILROC CZ to manufacture a product that ensures that the ice cream vendor doesn’t have to touch the waffle cone.

As well as producing its own range of products and systems that provide protection, control and measurement for electrical installations; along with enclosures, switchboards, electronics and electromechanical devices for industrial machines, plant and related services, ABB works with other companies on custom manufacturing.

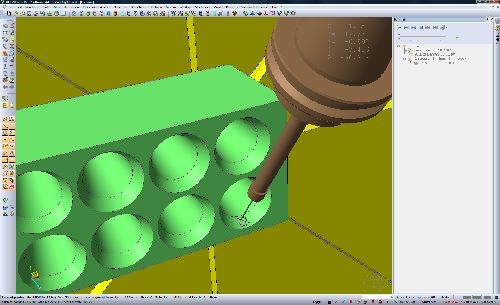

An example of this is the collaboration with SILROC CZ, which manufactures molded silicone products. The contract was for molds for silicone ice cream cone holders. The waffle cone drops into the silicone holder, ice cream is dispensed and the customer takes it without the vendor touching it.

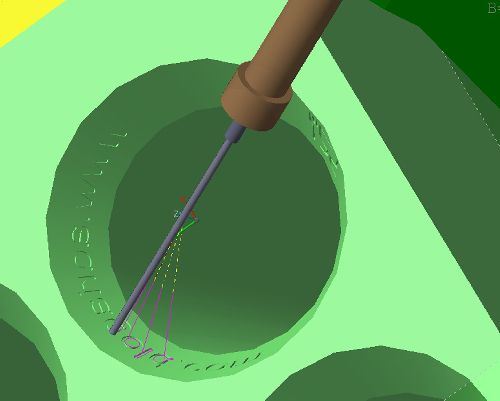

The mold was constructed at SILROC, which has used VISI for modelling and 3D machining since 2001. The part was then machined at ABB on a 5-axis HERMLE C 40 u machine. The most challenging aspect was engraving the upper conical wall of each holder, which was achieved with simultaneous 5-axis machining between two surfaces.

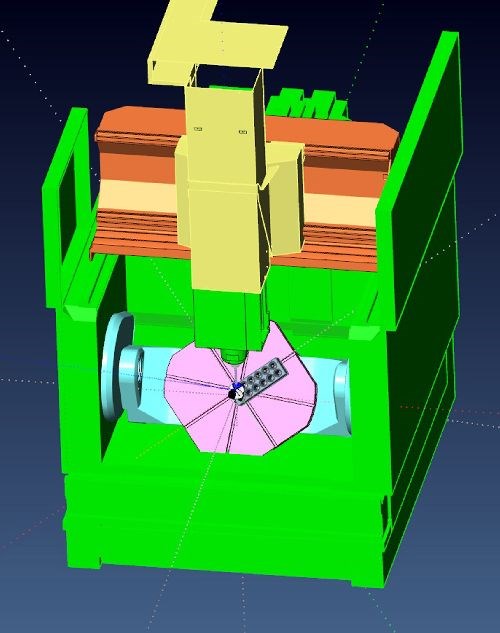

Using a model of the machine created for ABB by VISI, machining was tested on one position and then moved to the other conical holders with VISI’s kinematic simulation maintaining no collisions.

The 1-mm diameter coated carbide milling tool had an overhang of 200-mm to avoid colliding with the spindle, and was clamped in a long, narrow holder.

ABB now has all machining technologies from 2D to simultaneous 5-axis, along with wire erosion. VISI started working with them around a decade ago, supplying VISI as their principal CAM system for milling, and they have also recently upgraded to the latest VISI PEPS Wire technology.

Machines include a Mikron VCP 600, HERMLE C 40 U and MAHO DMC 1035 mills; EDM wire eroders Makino EU 64 and GF AgieCharmilles AC PROGRESS V2; and Makino and Ingersoll EDM sinking eroders.

VISI enables them to produce high quality parts, quickly and cost effectively. They have mastered VISI for their needs very quickly, which considerably reduced programming time.

_300x250 4.png;maxWidth=300;quality=90)

_970x250 1.png;maxWidth=970;quality=90)