Don't Just Be a Statistic - Be A Part of The Moldmaking Industry's First Statistical Report

Sound business decisions are built on the basis of good information. That is why the SPI Committee on Equipment Statistics (CES) and the Moldmakers Division of The Society of the Plastics Industry, Inc. (SPI) have embarked upon a statistical program.

How does your business compare to the overall state of the moldmaking industry? Could there be opportunities for growth in areas of which you are not even aware? Do trends indicate that you should reduce your activities in some specific areas and increase them in others? Is there a benchmark you can follow on an international basis? If you do not have answers to all of these questions, you're not alone.

Needed Information Is Lacking

Sound business decisions are built on the basis of good information of which the moldmaking industry is lacking, especially regarding volumes of and markets for molds. That is why the SPI Committee on Equipment Statistics (CES) and the Moldmakers Division of The Society of the Plastics Industry, Inc. (SPI) have embarked upon the statistical program referenced in our June article.

This program to gather critical statistical information on the U.S. moldmaking industry will reside within, and be similar to, the well established CES statistical program for injection molding, blow molding and auxiliary equipment that provides market data for those segments. Like its parent, the new program's goal is to provide the most complete, accurate and timely statistical reports possible for its own area of focus and provide a wealth of information never before available. The addition of the mold statistics to the data garnered in the larger equipment statistical program also will contribute to the information available on the health of the overall industry.

Moldmakers Urged to Participate

The Committee on Moldmaking Statistics will begin collecting data from the industry on January 1, 2001. In the meantime, it will finalize the data request forms and a test group of SPI moldmakers will be asked to complete the confidential survey.

On January 1, all companies that manufacture or import molds, mold bases or components for the plastics industry will be invited to participate in the moldmakers statistical survey. Only those companies that submit data will be eligible to receive reports.

Of course, all of the information submitted will be held strictly confidential. No individual company data will be made known. To facilitate this, all of the data will be submitted to a third-party fiduciary through company codes known only to those submitting data and the fiduciary. In addition, many safeguards implementing U.S. antitrust laws will be followed to the letter to ensure that no report inadvertently shows individual company data.

Obviously, the value of this program depends greatly upon strong industry participation, and SPI encourages all moldmakers to get involved.

Statistics Collected Will Span the Sector

Data will be collected for plastic injection molds in the categories of thermoplastics injection molds, thermoset plastics molds, injected metal molds and thermoset plastics compression molds by press tonnage. Another category, thermoplastics blow molds, is classified by type.

Information gathered for injection molds includes units and dollar amounts of orders and shipments for molds manufactured and sold in the U.S., molds exported and molds imported. These numbers are broken down by tonnages of 0-499, 500-999, 1000 and greater.

For thermoplastics blow molds, the same information is broken down by four types: injection blow, stretch blow, continuous extrusion and accumulator head.

Mold base data will be collected according to size in three size categories. Mold component information will be collected by shipments manufactured and sold in the U.S., exported and imported, by dollar value only.

Another portion of the mold survey will collect data as to units and dollar amounts shipped by end market. The draft survey breaks down the markets into agriculture, building and construction, electrical/ electronics, furniture, housewares, industry, medical, packaging, plumbing, toys, transportation, yard and garden and other. Data also will be collected regarding quotes for new molds.

Moldmakers Can Help Themselves And the Industry

Again, only those moldmakers who participate will receive the information, and wide participation is needed to create the most valuable product. Moldmakers are encouraged to take part in this landmark program to produce information never before available.

To find out how you can get involved in the moldmaking statistical program, contact Lori Anderson, SPI director of economic and international affairs at (202) 974-5281 or via e-mail at landers@socplas.org. To find out how you can get involved in other initiatives of the SPI Moldmakers Division, contact Walt Bishop, the division's executive director at (202) 974-5230 or via e-mail at wbishop@socplas.org.

Related Content

Predictive Manufacturing Moves Mold Builder into Advanced Medical Component Manufacturing

From a hot rod hobby, medical molds and shop performance to technology extremes, key relationships and a growth strategy, it’s obvious details matter at Eden Tool.

Read MoreOEE Monitoring System Addresses Root Cause of Machine Downtime

Unique sensor and patent-pending algorithm of the Amper machine analytics system measures current draw to quickly and inexpensively inform manufacturers which machines are down and why.

Read MoreMold Design Review: The Complete Checklist

Gerardo (Jerry) Miranda III, former global tooling manager for Oakley sunglasses, reshares his complete mold design checklist, an essential part of the product time and cost-to-market process.

Read MoreTackling a Mold Designer Shortage

Survey findings reveal a shortage of skilled mold designers and engineers in the moldmaking community, calling for intervention through educational programs and exploration of training alternatives while seeking input from those who have addressed the issue successfully.

Read MoreRead Next

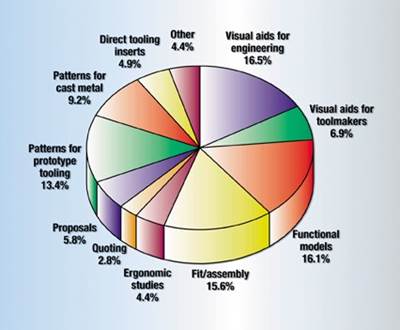

Rapid Prototyping and Tooling - State of the Industry 1999: Executive Summary

Rapid prototyping (RP) refers to the physical modeling of a design using a special class of machine technology.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More

.png;maxWidth=300;quality=90)