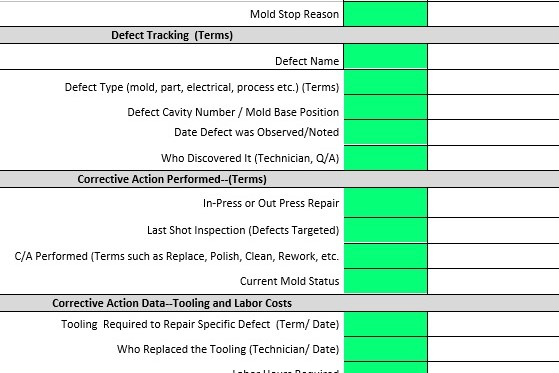

Sample of the scorecard/test that will be sent to attendees after they complete their registration for this free March 30th webinar on mold maintenance documentation.

Yep, a free webinar will issue a scorecard or test to attendees to help them better understand how their toolroom stacks up with other toolrooms when it comes to how well they document their mold maintenance.

After attendees register they will be issued this scorecard to review and have on hand during the webinar, as Steve Johnson and Glenn Keith of MoldTrax Maintenance Solutions explain the components of the test, provide instructions for taking the test and then reveal and explain the 5 scoring ranges so attendees can gauge their toolroom’s 4.0 mold maintenance documentation capabilities.

Steve Johnson is the President of MoldTrax Maintenance Solutions, a provider of maintenance training products and services. With 40 years of experience in the tooling industry, including eight years as senior tooling engineer for Abbott Laboratories/Hospira and 24 years as a toolmaker at Calmar Inc., repairing and rebuilding high cavitation close-tolerance multi-cavity molds. Prior to Calmar, Steve served six years in the U.S. Navy working as a jet mechanic on the A4L Sky-hawk, and majored in mechanical engineering at Southern State University. He has also designed and developed MoldTrax, a leading documentation software system for tracking mold performance and maintenance, and author’s many articles for plastics industry magazines.

Glenn Keith has 35 years of experience in mold maintenance, including a

four-year apprenticeship, then 15 years as a repair technician repairing and rebuilding blow molds, injection molds and various hot runner systems for the automotive, caps and closures and packaging industry at Whirley Drinkworks, Erie Plastics and Loranger Manufacturing. He then moved into management where he supervised the mold repair area for 16 years. Today Glenn is a training and assessment manager for MoldTrax LLC where he conducts Maintenance Capability Assessments for companies around the world and also trains on the implementation and use of the MoldTrax maintenance software—MTWEB.

Register Today to attend this interactive webinar.

Related Content

-

The Secrets to Hard Milling Success

The Secrets to Hard Milling Success

-

Predictive Manufacturing Moves Mold Builder into Advanced Medical Component Manufacturing

From a hot rod hobby, medical molds and shop performance to technology extremes, key relationships and a growth strategy, it’s obvious details matter at Eden Tool.

-

Questions and Considerations Before Sending Your Mold Out for Service

Communication is essential for proper polishing, hot runner manifold cleaning, mold repair, laser engraving and laser welding services.

_300x250 1.png;maxWidth=300;quality=90)

_970x250 1.png;maxWidth=970;quality=90)