CAMM Members Contribute Skills for Windsor Rotary Centennial

Members of the Canadian Association of Mold Makers (CAMM) contributed time and skills to create sculptures for the new Rotary Club of Windsor (1918) Centennial Plaza.

Members of the Canadian Association of Mold Makers (CAMM) recently participated in a civic project that required their metalworking skills on a more artful level than even mold making does. “Our Rotary Club is 100 years old this year,” Janet Kelly, Chair of the Rotary Club of Windsor (1918) Centennial Legacy Projects Committee, says. “We've been very active in the community over the years and many of the projects and things we've built have disappeared over time, so we formed a committee to look at how we could do a sustainable project as our legacy.”

The committee came up with five Centennial projects, and Kelly met with City of Windsor officials and asked them if there was anything on their wish list that Rotary could partner with them on. “They have a five-year plan to develop pieces of the river front and asked us if we would like to work with them to develop the piece of land just west of the Festival Plaza,” she says. The Rotary Club agreed and with approval by the City Council, Windsor’s landscape architect Stefan Fediuk and Mike Clement, Manager, Parks Development, undertook the task to design what would become the new Rotary Club of Windsor (1918) Centennial Plaza.

Enter the CAMM, whose members were asked to partner with Rotary by machining and assembling five sculptures (two large and three smaller versions of the same design), which were designed by Fediuk, out of aluminum. “CAMM President Jonathan Azzopardi of Laval International, Mike Hicks of DMS (Canada) Ltd. and CAMM Executive Director Diane Deslippe were instrumental in bringing CAMM members into the project. CAMM stepped up largely to build the sculptures for us and helped us with some design modifications because they had better ideas than we did,” she notes. “They’re very creative. The sculptures needed to be cut, polished and coated—it was quite a process.”

“Dianne Moore, who was the CAMM’s first executive director, is also a devoted Rotary member,” Hicks says. “When she heard about this project she asked Janet to contact me and that is how the ball got rolling. I was smart enough to realize that if Rotary 1918 and the City of Windsor were involved, and it meant developing that great, undervalued riverfront location, it would be a world-class project. Our CAMM members operate at a very high quality level and know how to deal with and meet deadlines, so I knew it would be a good fit.”

Hicks, who serves as the CAMM’s second vice president, says that when he presented the idea to the organization’s board of directors, the decision was unanimous to support the project. The board then set out to generate donations, in-kind services, materials, design input and modifications, and so on. “Jonathon served as the general contractor on the project,” Hicks notes. “Without his leadership and determination this project would not have been completed on time and at a high level of quality.”

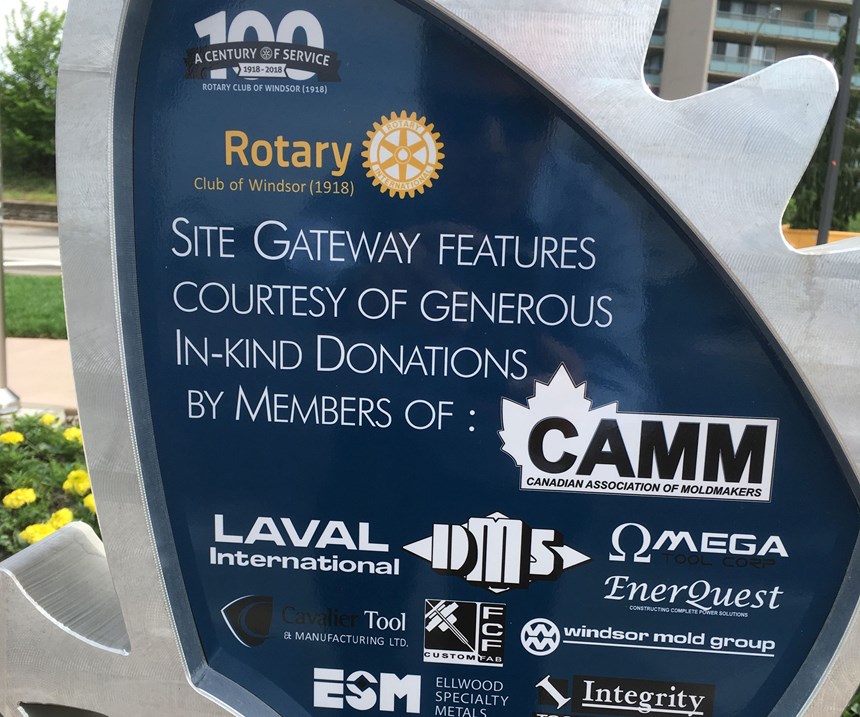

In addition to Laval International and DMS, the following CAMM member companies actively contributed to the manufacture of the sculptures: Cavalier Tool and Manufacturing Ltd., Integrity Tool and Mold Inc., Omega Tool Corp., Windsor Mold Group, and Ellwood Specialty Metals. Hicks adds that FCF Custom Fab and Enerquest “did an outstanding job waterjet cutting and blasting (respectively) the trellis and sculptures in Centennial Plaza.”

On May 29, Rotarians and CAMM members alike gathered at the Centennial Plaza to officially open it to the public. Visitors to the plaza’s main entrances are greeted by the large-sized gateway markers that feature shell-shaped gears meant to communicate that the Rotary Club’s service to the community is eternally ongoing, according to Kelly. These, and the three smaller versions placed at other entrances, welcome visitors in 40 languages. A trellis that shelters benches and a geodesic kinetic art piece by artist Nicolas de Cosson are central to the overall plaza, and there are walkways, adult swings, picnic tables and even a large, concrete ping pong table.

It should be noted that this project is not the first on which the CAMM and Rotary Club of Windsor have collaborated. “In 1993, we worked with CAMM and the mold makers in town to build something called the Hart Walker, which was named for the doctor who designed it,” Kelly says. “It was an assistive device like the old walkers that toddlers would sit in to learn to walk. There was a platform at the bottom and then the children would wear a belt around their waists and there would be wires attached to it to allow children who were paralyzed from the waist down to be mobile. More than 100 local companies and Rotary volunteers were involved in the building and assembly of 150 walkers, which were given to children. When they were no longer used here they were donated to third-world countries.”

Related Content

Women Impacting Moldmaking

Honoring female makers, innovators and leaders who are influencing our industry's future.

Read MoreMold Builder Uses Counter-Intuitive Approach for Mold Challenges

Matrix Tool Inc. answers customers’ hard questions with creative solutions for cavity spacing, tool sizing, runner layout and melt delivery that reveal the benefits of running in a smaller press size at lower cavitation but higher yield.

Read MoreEditorial Guidelines: Editorial Advisory Board

The Editorial Advisory Board of MoldMaking Technology is made up of authorities with expertise within their respective business, industry, technology and profession. Their role is to advise on timely issues, trends, advances in the field, offer editorial thought and direction, review and comment on specific articles and generally act as a sounding board and a conscience for the publication.

Read MoreMold Design Review: The Complete Checklist

Gerardo (Jerry) Miranda III, former global tooling manager for Oakley sunglasses, reshares his complete mold design checklist, an essential part of the product time and cost-to-market process.

Read MoreRead Next

Are You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More

.png;maxWidth=300;quality=90)

_300x250 1.png;maxWidth=300;quality=90)