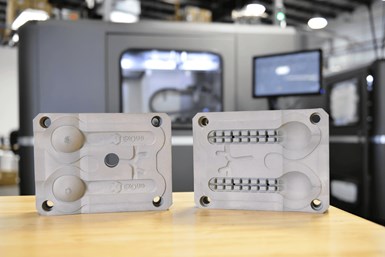

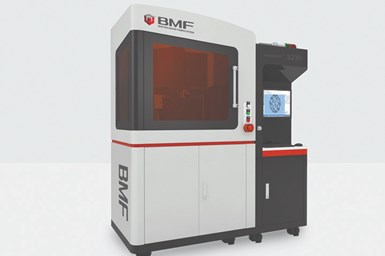

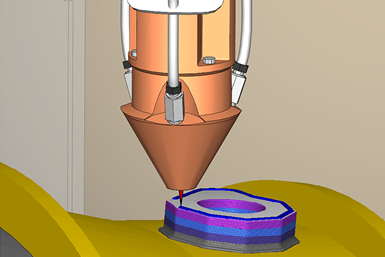

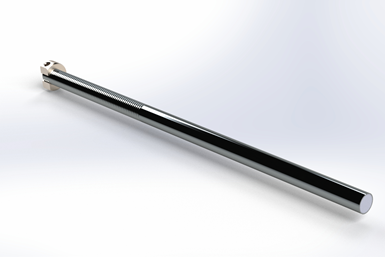

Photo Credit: (top left) Next Chapter Manufacturing, (top right) ExOne Co., (bottom left) CGTech and (bottom right) AddUp Inc.

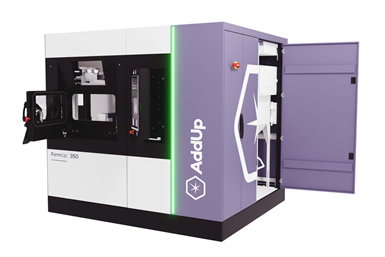

Additive manufacturing (AM) continues to build new opportunities for moldmakers, from saving on energy and material waste, decreasing cycle times, enhancing part reliability, eliminating design constraints and a host of other advantages.

This trend is also being observed in the new software, equipment and materials offered to the industry, which is exemplified below, as well as in MoldMaking Technology’s upcoming December 2021 print/digital issue.

See what you might have missed below!

For additional information covering this topic, including case studies, a directory to primary AM-related suppliers and MMT Chats focused on this topic, take a look at the “Read Next” section.

Related Content

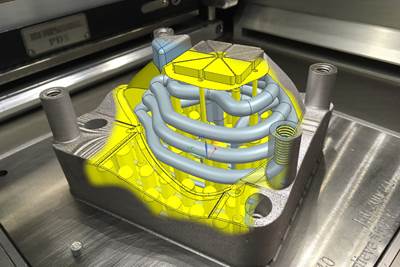

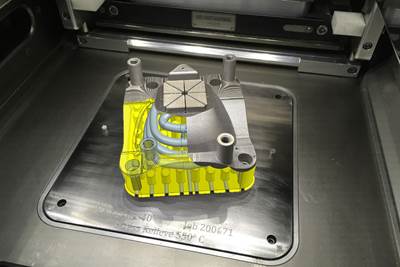

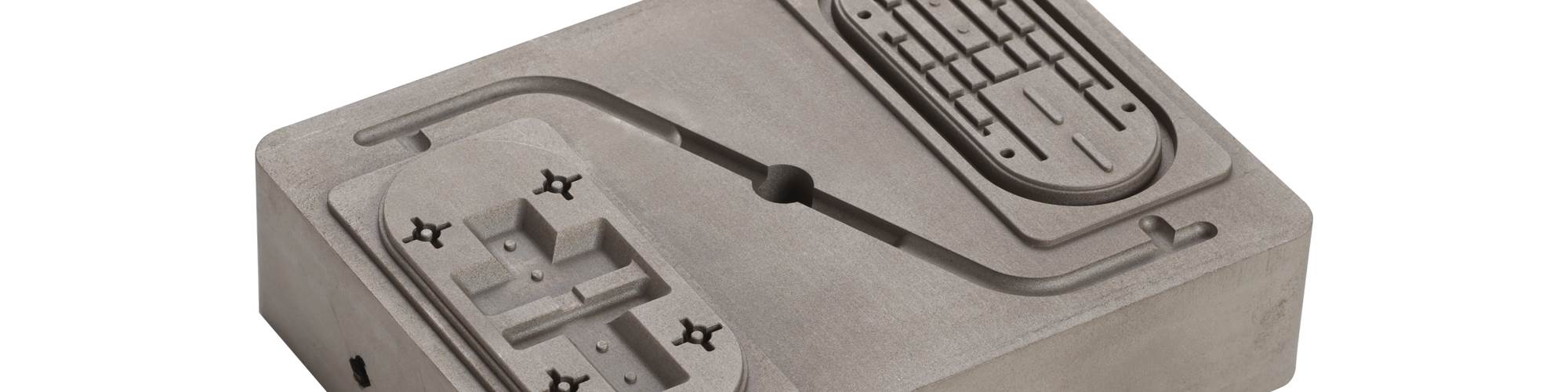

Evaluating Metal Powders for Conformally Cooled Mold Inserts

Mechanical properties and design software techniques reveal the benefits of a modified high thermal conductivity metal powder for 3D printing in moldmaking.

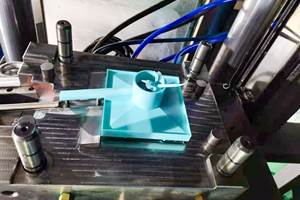

Read MoreVIDEO: How can 3D Printed Tooling Improve Injection Mold Venting?

Proper venting is one of a mold builders toughest challenges as molders struggle to keep vents free flowing in production. Learn how to apply 3D printing to mold venting and the benefits of additive venting inserts.

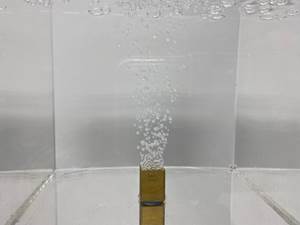

Read MoreVariable Density-Coated Tool Steel for High-Wear Molds

A mold builder can have an abundance of venting and fully dense solid areas in steel by using variable density sintering to eliminate gas trap defects in high-wear molds.

Read MoreA 3D Printing Retrospective

A personal review of the evolution of 3D printing in moldmaking throughout the past 25 years.

Read MoreRead Next

Growing AM's Presence in Moldmaking

Advanced Michigan mold manufacturer advocates for additive manufacturing in moldmaking through collaboration and education.

Read More2021 Sourcing & Technology Guide: Additive Manufacturing

3D printing, or additive manufacturing, simplifies the moldmaking process by making mold inserts, mold components, end-use parts and ancillary equipment.

Read MoreHybrid Approach to Producing Mold Inserts Boosts Productivity and Profitability

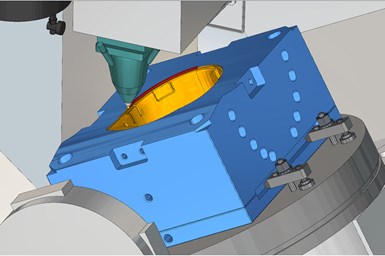

Mold inserts with additively produced cooling circuits eliminate design constraints, reduce the cost of complexity, improve part dimensions, decrease cycle time and speed time to market.

Read More

_300x250 1.png;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)