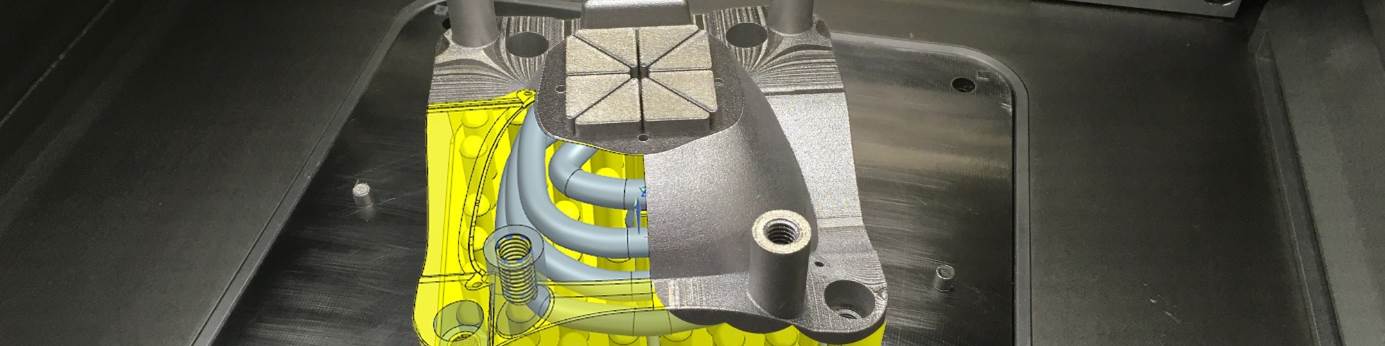

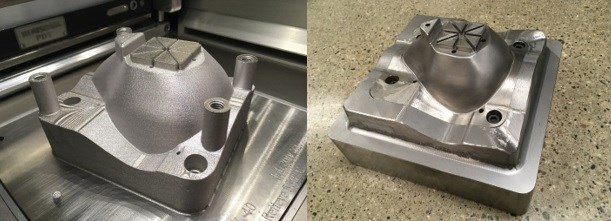

Action Mold and Machining designed this Take Action Face Mask with conformal cooling and post-processing fixture features. It is important to note that the four threaded pillars in the corners of the part will be used as fixturing during post-processing of the part, giving easy access to the bottom of the part. They also allowed for a more gradual transition in the cross-section of the printing process, avoiding large thermal shifting when the larger base ended. Photo Credit: Action Mold and Machining.

What is Action Mold's chief competitive advantage?

Matthew Duffey, Marketing & Advanced Development for AM: It's our holistic view on the entire mold manufacturing process. We understand additive manufacturing (AM), EDM, machining, polishing, plastic injection molding and metrology. We are not just designing and printing a part; we are designing, printing, machining, finishing, polishing in some cases, and even processing the molds. We deliver concept to end-use product.

The moldmaking side of the operation where engineering changes, repairs and preventative maintenance happen.

“We know because we do” sums up our philosophy. We believe that before we sell a technology or service, we need to understand and embrace it ourselves all the way through the running of the mold.

Featured Content

When it comes to AM, we understand that printing inserts with cooling built into a component and close to the cavity shape provides shorter cycle times via cooling the hot spots quicker and reduces part warp.

Also, if we need to print a part and then machine it, we determine beforehand how we're going to fixture and stabilize the part for post-processing. If we are printing a part for the customer to post-process on their own, we will meet with them to discuss and strategize their post-processing setup. At the same time, we will share how much stock should be left on areas to be machined.

A skilled tradesman at work spotting shutoffs to ensure a ‘no flash’ condition in the steels.

Our goal is to shift our internal and customer thought process to incorporate AM capabilities at the start of the design process. We incorporate venting and cooling in a single component. This will improve tool performance and reduce tooling problems.

What has been the most significant change in Action Mold's use of technology?

Duffey: Keeping the shop current with the latest technology is always a challenge, especially for a smaller shop like ours—whether it's making sure our software is the latest version or upgrading the electrode tool changers on the EDM machines for extended lights-out operation. In each case, we keep an eye on what is needed next and focus on identifying and eliminating bottlenecks.

For example, we invested in five-axis machining, bought a new CMM equipped with a blue light scanner and purchased a new wire EDM. The most significant change is the implementation of AM and the integration of processing printed components through the departments. The addition of AM is made possible with the support of the rest of the shop, and in most cases, AM is not a standalone technology to make an end-use part of the tooling world.

Action Mold was able to do it all in-house. We had control of the whole process—from AM to molding.

Action Mold has moved deeper into AM. Can you talk about the barriers to AM for a mold builder, as well as the ROI of additive tooling?

Duffey: The most significant barrier we face right now is convincing the mold buyer that a mold built with this technology holds greater value. Yes, the tooling does cost more; however, the ROI (for the mold buyer) is realized when the mold is placed in a molding machine and shorter cycle times are achieved. This is the challenge because tool buyers may not understand the potential product quality impact of AM and are incentivized to stay below a specific price point for tooling instead of seeing the long-term cost savings of a more efficient tool. Those in tooling procurement need to be educated.

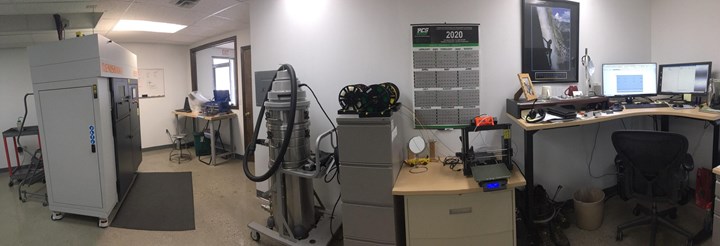

A panoramic view of Action’s AM lab that includes a design and file preparation workstation, an FDM printer, a Renishaw AM400 and a vacuum for metal powders.

In other instances, some customers want a part the next day. They don't realize that, depending on the intended use, printing (and finishing) a part may take longer than machining the part traditionally, especially if it needs to print, stress relief, machine, heat treat, etc. It all takes time. There is some significant education still needed.

In industries using AM to produce a finished part (that had been traditionally manufactured), it is common for them to go through a requalification process before it can be used. This is because even if the material is chemically the same, the processes that the material goes through to create the AM part will result in different mechanical properties.

For example, if a direct replacement part for aerospace, originally cast in Inconel 625, is replaced by a printed part in Inconel 625, it will have different properties. This leads to necessary qualification of the replacement part as an equivalent part, which typically requires many mechanical test samples such as density blocks, tensile bars, fatigue samples, corrosion blocks, etc. This evaluation happens before the desired part is even built, which can be an expensive, time-consuming process. The final part is then printed and goes through further evaluation to ensure it is performing to the same specifications as the original part.

Using AM to produce tooling does not require such extensive testing. The end parts are molded in the same machine as the original part, just faster and often with better quality. The mold runs more efficiently, and the result is a part with equivalent mechanical properties, which allows for the integration of AM tooling directly into the manufacturing process without causing any production delays.

When evaluating the ROI of an additively manufactured tool, it is critical to include the tool's performance. If the traditional insert cost $10,000 with a cycle time of 30 seconds per part, the AM insert cost $15,000 with a cycle time of 15 seconds per part. This means that the AM insert may cost 50% more but is producing the same number of parts in half the time. You fill your order in half the time.

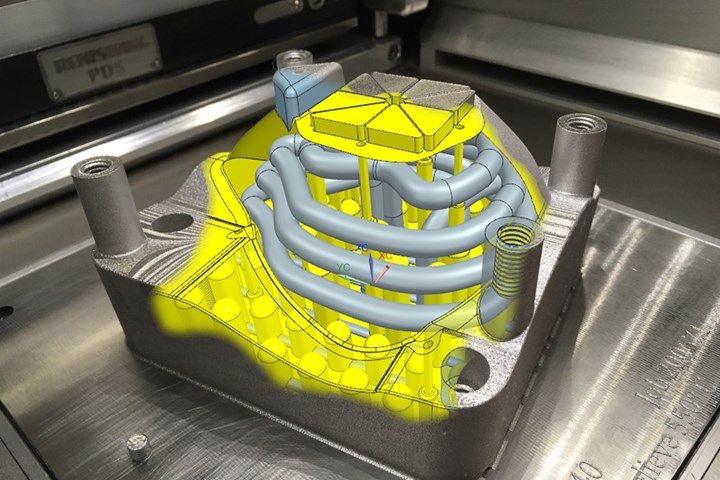

An example of laser powder-bed fusion hybrid part manufacturing. Action Mold incorporated conformal cooling channels and venting ports on top of this traditionally manufactured base fixtured into its Renishaw AM400 printer.

You are definitely advocating for AM in moldmaking. Would you mind sharing why that is so important to the Action Mold team?

Duffey: What has been missing amidst all the hype about AM is proof that your molds will perform better, and that you will be able to reduce your cycle time. There has been little to no data, only cool parts, and many molders and mold manufacturers are not receptive to that kind of technology.

It's all about education. When someone comes in with a new mold, we want to show the value of integrating AM. We want to show people what's possible with conformal cooling via AM to equip them better to design a part for conformal cooling themselves. Even if that customer goes with another shop, we are at least getting the word out about AM into the industry a little bit more. Our focus right now is on growing the AM presence in moldmaking applications.

We're trying to be as transparent as possible with projects that we do internally to showcase the reality of what needs to be done when it comes to AM and the resulting performance. We want to collaborate to build awareness and case studies to demonstrate the value added through AM. We continue to get our team and customers more engaged with AM, so AM becomes part of the standard process.

Who makes up your current Additive Team?

Duffey: Greg Nemecek has been with Action Mold for 10 years. He has been running the whole additive initiative. He spent a lot of time learning as much as he could about additive technology and picked up AM's value very quickly. He understood how they could use the technology and worked with Renishaw to determine ancillary support for AM. (For example, it's not just the printer. You need the equipment to break down a build, de-powder the parts to make it safe for others to handle, remove them from the plate, etc.) Then, in the winter of 2018, after considerable training on the software and design side of AM, Action Mold purchased a Renishaw AM 400 laser melting system, took delivery of the machine in April of 2019 and started printing in May.

Action Mold uses this Coord3 CMM with a Renishaw PH-20 five-axis touch probe and a Kreon blue light scanner for engineering changes. Steels are checked each pre- and post-change. Then, a report is created and supplied to the customer showing steel conditions before and after the engineering change. The Kreon blue light scanner is used to reverse engineer tooling that comes in with no CAD models.

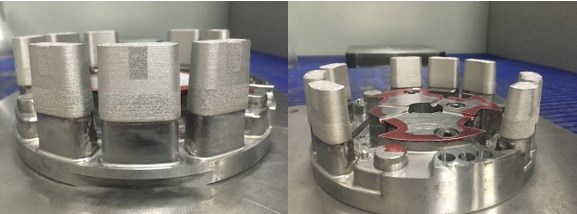

Greg hired Zachary Glascock in April of 2020 after he graduated from Western Michigan University. His senior design project was working with Action Mold, testing different geometry to vent molding gases. Those tests proved inconclusive. However, it was a great introduction for Zach into the world of laser powder bed printing. Once we had Zach onboard with Action, he began refining the porous print parameters (developed by Renishaw for Action Mold), which enabled them to create their porous inserts instead of relying on the diminishing supply of Porcerax. Action Mold can produce a one-piece insert with venting built directly into the part. Zach helped establish different performance metrics and parameter sets for vented inserts to consolidate parts, allow for new design freedoms, eliminate the bottlenecks of trapped gases and cool at the same time. We can do a lot of different things once we have the data to back up our understanding of the vented parameters.

Today, Greg is focusing on managing and designing for AM as well as managing the CMM department. Zach is running and monitoring the additive machine and is the CMM operator. I handle more of the marketing, lead the internal training and guide future R&D work to make our process more robust. We are always looking for ways to run the machine differently to reach a more consistent and better-quality product.

I believe moving forward, it will be all about designing for AM where AM makes sense. Not every part requires AM, but where complex shapes make for difficult cooling and part manufacturing, it should always be considered.

I got to know Greg at a software event by Altair hosted at Renishaw over two years ago when Action was working on its paperwork to purchase a machine. After this event, discussion with Renishaw accelerated as the machine acquisition and preparations of the Action Mold building got underway. I was on the phone with Greg every other day for about a month, answering questions on the facility requirements, such as necessary power, ventilation, gas and shop floor layout, material handling and storage, as well as coordinating Greg's training. That is how I got to know them.

Action Mold investigated the use of porous printed material to perform as vents in a mold to help eliminate gas traps, which allows venting nearly anywhere in the insert and in any shape. AM also reduces the steps to manufacture the vented regions as compared to traditional processes. Action Mold is also developing print parameters that will yield greater consistency in the vent region and provide different gas flows depending on the vent’s requirement.

I was supporting Action Mold through the final stages of technology selection in the winter of 2018 when I worked at Renishaw. In June of 2019 I relocated to Buffalo, New York, to work for Edison Welding Institute (EWI) in their AM group. I kept in touch with Action Mold to see if there were any mutually beneficial projects that we could do to increase the awareness and understanding of using AM for tooling and molds. Through working on projects together, I was able to bring Action Mold into the Additive Manufacturing Consortium run by EWI, the primary focus being increased AM exposure to the automotive industry. It later made sense for me to join the Action Mold team in October of 2020 to work remotely because they had enough people with hands on the systems and needed AM engineering experience.

Through all of this, I learned that Action had end-to-end capabilities to design, machine, polish, measure and test a part. AM was a perfect fit for their business model. One of the best reasons that I chose to join the Action Mold team, besides the quality of people working there, was that I could continue to learn and build experience with end-to-end manufacturing using AM.

What training and technology tips can you share when it comes to using AM?

Duffey: Early on, you rely on the machine supplier for parameters and your powder supply. That's changed a bit over the years because to embrace AM, you need to be able to purchase your own powder. I always recommend that you spend time just learning the equipment you have before trying to do more. Companies that don't spend time running and learning how their machine behaves with established parameters will have problems. They get in their own way.

You need to understand that anyone can run the machine, but you need to do more than just run the machine to get the most out of it. My recommendation is for the person to run the machine initially is a toolmaker or skilled machinist. They bring experience with getting the most out of a machine tool applied to the new technology. You need to marry the old-school thought process (or skillset) with the new-school technology of AM.

Further, when choosing the appropriate AM technology, I believe it is crucial to find the AM technology that fits your business. For example, if you do metal injection molding and have experience with de-binding and sintering a part, then binder jet technology is a good fit. For producing molds, laser powder-bed fusion makes the most sense because you can produce a fully dense near-net shape that will fit right into the machining processes already employed. If the business is primarily tooling repair, then DED technology could make the most sense because it can bring automation and consistency to the weld zones of the repaired molds.

It's all about education. When someone comes in with a new mold, we want to show the value of integrating AM.

How has the addition of AM impacted new tooling orders, and how do you expect Action Mold to evolve in the next three to five years?

Duffey: We have experienced an increase in new tooling work in 2020, in part by simply having the technology in-house and having conversations with customers about our additive capabilities. Although some of our big customers are not quite ready to travel the AM route with us, they have told us that knowing we have these capabilities will cause them to consider how they can integrate AM in new tooling down the road.

I believe moving forward, it will be all about designing for AM where AM makes sense. Not every part requires AM, but where complex shapes make for difficult cooling and part manufacturing, it should always be considered.

We also strive to be a comprehensive resource for the tooling world as the need for local manufacturing increases. We want to be able to support that. If we're going to increase molding in the U.S., we need to improve molds built in the U.S continually.

Can you describe the most notable AM project that Action has worked on recently?

Duffey: We are trying to use it for any part that is an AM candidate. We started with conformal cooling aluminum die-cast-dies, and then we looked at in-house parts/projects to use the data and share the application stories.

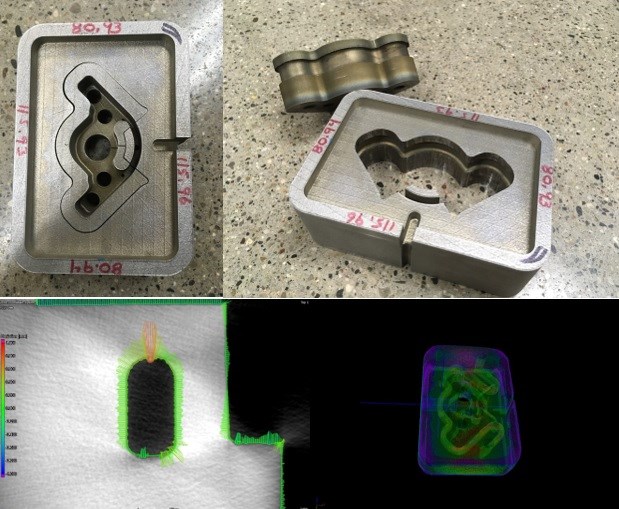

For example, the first ‘internal’ part we did was adding conformal cooling that took a 38-second cycle time down to 23 seconds—a 45% reduction. This project was done with EWI as a case study to take a deeper look at AM tooling applications and realities. We were able to get more metallurgical analysis done as well as X-ray CT imaging of our part.

This allowed us to track any geometric deviations in the part throughout the process. We could then compare the cooling channel dimensions to CAD and evaluate the surface quality. This would not have been possible with traditional non-destructive techniques like CMM.

This conformal cooling application reduced cycle times from 38 seconds to 23 seconds. The overall tool with a cutout profile to show the internal channels (top left), the cutout removed exposing the conformal channel (top right) and an X-ray CT scan of the insert for inspection of cooling channel geometry and printing accuracy as compared to the CAD model (bottom left and right). Note that the red region in the bottom left image shows the top center area of the channel slightly collapsed but still fully dense, which is a common result with horizontal overhanging surfaces of holes in laser powder-bed fusion

An exciting project involved a face mask to help fight COVID-19. The cycle time for the original design was quite high, and some areas were just too thick to cool efficiently. Greg thinned those out a little bit and added conformal cooling. The primary time improvement was accomplished by changing the thickness of the molded material. Cycle time went from 120 to 45 seconds, and this was only possible because Action Mold was able to do it all in-house. We had control of the whole process—from AM to molding.

Action Mold’s Take Action Face Mask (TAFM) insert as-printed with machining stock and fixture features for post-processing (left). The finished machined insert before going to molding (right). Notice the pillars printed in the corners have been removed after the bottom surface was finished.

The latest project to receive a conformal cooled insert is an horticultural mold. This part had less room for cycle time improvement as it's a thin-walled part. However, by adding cooling, we more consistently control the temperature at ejection, reducing the warpage to reduce scrap rates.

The uses for additive in tooling will continue to grow, and there's much more to come. Collaboration with customers and pushing the technology to new limits will reveal the true potential of AM in molding.

RELATED CONTENT

-

Mold Design Tricks, Additive Manufacturing Treats & More: MMT's Top-Viewed Articles in October

October held some tricks but mostly treats for MoldMaking Technology’s audience.

-

IMTS Showcases Software, Additive Manufacturing, Inspection and Measurement Tools for Moldmakers

MoldMaking Technology previews a selection of the software, additive manufacturing, inspection and measurement tools that will be present at IMTS.

-

Mold Builder Uses Metal 3D Printing to Bridge Medical Product Development to Production

Westminster Tool uses metal additive manufacturing for medical device OEM, taking lessons learned from R&D in the prototype mold phase to full-scale production molding in a fraction of the time.