High Speed Machining

Maximum RPM Machining: Necessities of High-Speed Moldmaking

Mold shops will thrive if they practice an ‘all-aspects’ process to HSM, which includes the machine, cutting tool, toolholder, proper balance and application support.

Read MoreCutting Tool Selection Impacts the Outcome of Hard Metal Machining

Effective cutting tools for the HSM of hardened die steel is an effective solution to a more profitable and easier machining process.

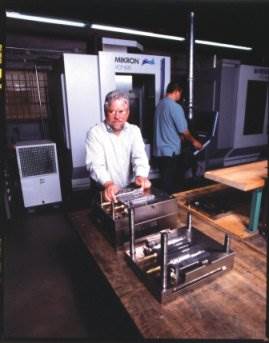

Read MoreHSM Equals Accuracy and Precision at Less Cost

A California moldmaker makes the most of state-of-the-art machine tool and design technology to deliver competitive advantages for a medical device customer.

Read MoreHSM Hikes Moldmaking Productivity

Achieving the full benefit of high-speed, hard-mold machining requires insight into tools and processes.

Read MoreThe Steps to High-Speed Machining

The transition to high-speed machining (HSM) is necessary to compete in today's global mold market.

Read MoreHigh-Speed Machining of Hardened Die and Mold Steels: A Total Concept

HSM of hardened die and mold steels is a proven concept composed of several components - all contributing to the cost-efficient machining of those specific materials.

Read MoreIssues, Trends and Developments in HSM

An overview of the state-of-the-art and future developments in moldmaking using high-speed machining processes for milling applications.

Read More

_300x250 3.png;maxWidth=300;quality=90)

_970x250 3.png;maxWidth=970;quality=90)