Search Results

Showing 11 – 20 of 137 resultsMark your calendars for the official announcement of these awards at PTXPO on Wednesday, March 29th at 2:30 PM at the Mold Technologies Division Booth 1614.

For his dedication to the moldmaking industry and for being a great leader and role model, Steve Johnson was selected and recognized as the 2014 Mold Designer of the Year for the Mold Making and Mold Design Division of SPE at amerimold 2014.

MMT's Editorial Advisory Board member Rick Seaburg from Medline Industries shares his top MoldMaking Technology articles of all time and how this content has been valuable to his businesses.

Toolroom technicians must include frame plates, frame components, and cavity tooling when developing a mold maintenance plan.

Molders, mold builders and repair technicians must fully understand thermal expansion to ensure they don’t damage critical seals during manifold repairs or routine cleanings.

At PTXPO, the 2023 Mold Designer of the Year, Mold Maker of the Year and Mold Repair Technician of the Year were awarded to Chuck Heitmeyer, Pat Roussey II and John Demakis Sr., respectively.

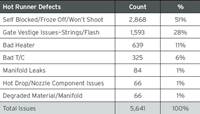

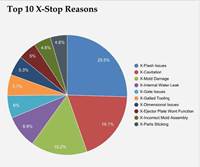

Part three of this three-part series explains how to use maintenance data, set targets and goals for improvement, and allow better, faster, and more accurate mold and part troubleshooting.

Many toolrooms want to replace manual entries with electronic data when creating maintenance work orders and providing past historical issues, corrective actions and the effectiveness level of resolutions, but technicians require more information than electronic signals can provide to prove a return on investment of their time.

The only thing that can mess up a solid PM plan for a manifold is a poorly designed system, and there are a variety of manifold designs and complexity levels. Many design features are the root cause of postponing a manifold PM until it breaks down.

Part one of this three-part series explains how to create a scientific maintenance plan based on a toolroom’s current data collection and usage.