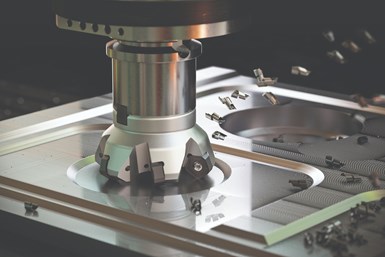

Face Milling Platform Combines Multi-Corner Milling, High Feed Rates

YG-1’s FM10 PNMU inserts are designed to separate the cutting edge and the wiper, which results in ten true cutting edges.

YG-1’s newly introduced FM10 PNMU face milling indexable inserts combine multi-corner face milling performance with high feed capabilities.

The FM10 PNMU inserts are designed to separate the cutting edge and the wiper, which results in ten true cutting edges.

The 36-degree entry angle reportedly generates thinner chips, providing operators higher feed capabilities. The curved cutting ridge and wiper design is engineered to reduce cutting forces and directs these forces axially along the strength of the machining center into the spindle. According to YG-1, these advantages optimize operational stability to provide users superior surface finishes and greater productivity.

YG-1 recommends FM10 PNMU cutters and inserts for milling in steel and cast iron. Now available in the U.S. and Canada, the cutters and inserts can be ordered in diameters of 2" to 4". YG-1 says it is developing an expanded range of diameters as well as extending the line for face milling in stainless and other materials.

Related Content

-

The Trifecta of Competitive Toolmaking

Process, technology and people form the foundations of the business philosophy in place at Eifel Mold & Engineering.

-

Developments in High-Speed Machining Technology

There have been many exciting developments in high-speed machining relative to machining centers and controls, tooling and CAD/CAM systems.

-

Predictive Manufacturing Moves Mold Builder into Advanced Medical Component Manufacturing

From a hot rod hobby, medical molds and shop performance to technology extremes, key relationships and a growth strategy, it’s obvious details matter at Eden Tool.

.jpg;maxWidth=300;quality=90)

_300x250 3.png;maxWidth=300;quality=90)