Tool Steel Alternative to S7-Based Molds

NPE2024: International Mold Steel showcases its DCMX steel as an alternative to S7, providing mold builders uniform hardness for even machinability and clean welds and other benefits.

With staff shortages prevalent, mold builders are searching for new efficiencies that allow them to provide timely service to their customers. International Mold Steel (IMS) claims to answer this call by providing its DCMX cold-work tool steel as a time- and money-saving alternative to S7 in plastic molds. IMS claims that DCMX is a better alternative to S7 for five reasons:

- Its chemical composition and production process makes DCMX easier to machine than S7 because it does not have coarse, unevenly distributed carbides that tear up cutters.

- DCMX is an isotropic matrix steel that is more stable in heat treatment.

- DCMX resists cracking during the welding process because it is tempered at a higher temperature than S7.

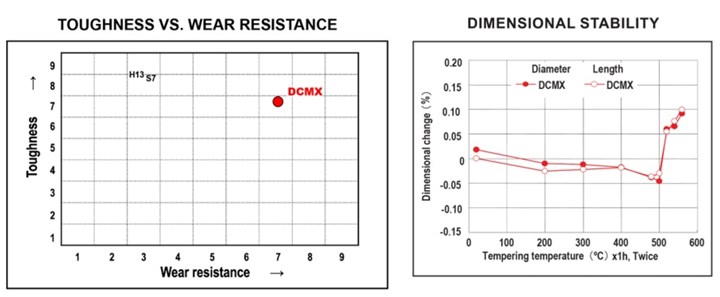

- DCMX delivers better wear resistance against abrasive resins due to higher hardness than S7 — 60-62 versus 52-56 HRC.

- DCMX provides higher hardness than S7 while maintaining similar toughness, which helps the mold builder deliver molds that perform longer with less maintenance.

Related Content

-

Making the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

-

Magnetic Mold Clamping Amplifies Quick Mold Changes

NPE2024: Stäubli highlights its adaptable QMC123 technology, which is capable of calculating the clamping force for each mold beforehand, in addition to ensuring worker safety.

-

Moldmaker Highlights Domestic Mold Expertise for Plastics Industry

MSI Mold Builders has the ability to develop a full range of injection molds and structural foam molds domestically, meeting the needs of U.S.-based molders.