Software Enables Hybrid and Additive Manufacturing in One Process

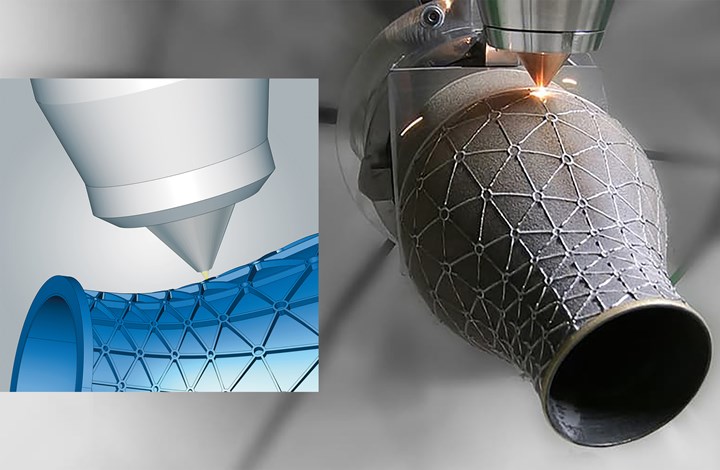

OPEN MIND Technologies AG offers an additive manufacturing (AM) capability option in hyperMill CAM software to support 3D printing/additive processes that also provides efficient hybrid processing with simultaneous additive and subtractive processing on one machine.

OPEN MIND Technologies AG offers an additive manufacturing (AM) capability option in hyperMill CAM software to support 3D printing/additive processes that also provides efficient hybrid processing with simultaneous additive and subtractive processing on one machine.

For highly complex five-axis simultaneous processing, the software enables an array of flexible options for directed energy deposition processes and wire arc additive manufacturing (WAAM). Both laser-based powder nozzle machining heads and WAAM can be controlled using the software for selective material deposition, as well as conveniently programmed and automatically simulated for collision avoidance.

Using powder bed fusion and any necessary rework, hyperMill supports the full potential of AM. The software also enables users to perfectly program the cladding and milling together. True-to-detail additive and subtractive simulation as well as stock tracking between the individual process steps guarantee the greatest possible reliability.

Key additive applications include repair of damaged components, cladding of additional surface skins, or creation of new components from a substrate. This also creates totally new options for combining different materials, such as when high-quality material layers have to be applied to carrier materials.

Related Content

-

OEE Monitoring System Addresses Root Cause of Machine Downtime

Unique sensor and patent-pending algorithm of the Amper machine analytics system measures current draw to quickly and inexpensively inform manufacturers which machines are down and why.

-

How to Select a Mold Temperature Controller

White paper shares how cooling channel analysis, which collects maximum pressure drop, total flow rate and heat dissipation, eases the performance evaluation of mold temperature controllers.

-

Leading Mold Manufacturers Share Best Practices for Improving Efficiency

Precise Tooling Solutions, X-Cell Tool and Mold, M&M Tool and Mold, Ameritech Die & Mold, and Cavalier Tool & Manufacturing, sit down for a fast-paced Q&A focused on strategies for improving efficiencies across their operations.

.jpg;maxWidth=300;quality=90)

_300x250 1.png;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)

.jpg;maxWidth=970;quality=90)