Parametric Design Software Drives Mold Manufacturing Automation and Efficiency

Tebis America’s third release of Tebis 4.1 features new interactive features for the everyday mold builder at IMTS 2022, including complete collision control and faster programming.

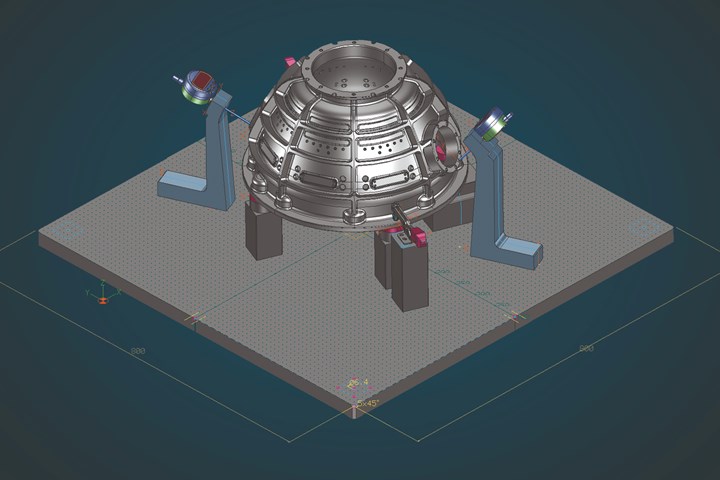

Tebis America recently launched its third release of Tebis 4.1, a complete

CAD/CAM system to drive automation and efficiency throughout the mold building process through the ability to perform tasks in design, manufacturing preparation and NC programming in a single system.

In the most current version, Tebis says the software system offers up to 85% faster programming, which in turn improves efficiency. The technology also enables mold builders to reduce manual intervention in CAM programming and calculate entire NCJob sequences at once by automatically applying interactively defined milling areas from previous NCJobs. CAM programming is also simplified and Tebis 4.1 reduces calculation time, additional features that company believes are important benefits for mold manufacturing.

New features to note in the third release include:

- A new function added specifically for active surface design in die manufacturing that can be used to quickly determine theoretically designed trim edges for flanges in deep-drawing and bending parts. Part material thickness is accounted for which generates precise results with no manual reworking required.

- Geometries like ribs and grooves with steep flank surfaces, straight bottom surfaces or starting and finishing radii can be machined automatically in three-axis and Z-constant mode, with a uniform step.

- Material removal simulation ensures safer manufacturing and is said to provide another strong argument for the verification of toolpaths in the CAD/CAM environment before NC output: The material present on the model is accounted for at every point in machining. The blank is then checked with updates in real time.

- Combined special tools including multiple cutting edge areas with different diameters which can be flexibly used for mill drilling and thread milling bores and circular pockets. This eliminates the need for tool changes and traverse movements with simultaneous process safety.

Attendees can learn more about Tebis 4.1 and other technology solutions at IMTS 2022 booth #133230.

Related Content

-

Advancing Moldmaking and Plastics: Trends in 3D Printing, Automation and Sustainability

NPE 2024 showcased the latest trends and technologies in innovation, efficiency and sustainability for moldmakers and molders, featuring advancements in 3D printing, automation, design and virtual reality/augmented reality/artificial intelligence.

-

Simplifying Cooling Design With Advanced Automation

CAD/CAM software with automated mold design features streamlines waterline, baffle and conformal cooling design, making it easier to act on insights from flow analysis.

-

How to Use Scientific Maintenance for More Accurate Mold and Part Troubleshooting

Discover how adopting scientific maintenance approaches helps improve mold lifespan, minimize failures, and optimize production outcomes.