New Modeling Partner Product

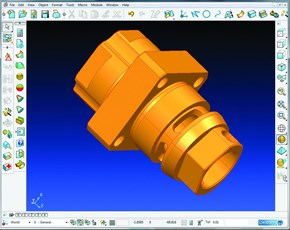

PowerSHAPE Companion for PartMaker, is based on Delcam’s PowerSHAPE design software.

Delcam has launched a new modelling partner product for its PartMaker CAM system for turn-mill equipment and Swiss-type lathes. The new product, called the PowerSHAPE Companion for PartMaker, is based on Delcam’s PowerSHAPE design software, which is already used at thousands of subcontractors and toolmakers around the world alongside Delcam’s PowerMILL CAM system for high-speed and five-axis machining. This new 3D CAD offering includes functionality for creating solid models, data repair, editing part designs for manufacture, and for the design of machining accessories, such as tool holders and machine components.

Like the PartMaker CAM suite, the PowerSHAPE Companion for PartMaker is based on the Parasolid Solid modelling kernel, assuring interoperability with both PartMaker and all other major CADCAM systems.

The data repair functionality in the PowerSHAPE Companion for PartMaker includes PowerSHAPE’s Solid Doctor. This allows users to read in, and repair, models from all sources, including standard formats like IGES and STEP, plus native files, such as CATIA, Siemens NX and Pro/Engineer, and output a file that can be read directly into PartMaker.

With the Solid Doctor, PartMaker users will be able to tackle all the common problems that can be found when translating low-precision and incomplete data, including gaps and overlaps between surfaces, or duplicated and missing surfaces, and generate a valid, high-precision solid model ready for programming.

The Solid Doctor uses a combination of automatic data repair tools, plus surface creation and editing options available within PowerSHAPE. This combination means that simple repairs can be carried out quickly and easily, while more complex problems can be overcome by deleting and replacing surfaces within the model.

The PowerSHAPE Companion for PartMaker will allow user to create 3D solid models from 2D drawings. It will also provide of range of other sophisticated CAD tools.

The PowerSHAPE Companion for PartMaker is also able to modify any aspects of the part that might cause difficulties in manufacturing. These could include adding chamfers to avoid secondary operations like de-burring, or adjusting or removing fillets that could add machining time and cost to a part. The same tools can also be used to generate any extra geometry needed for machining.

Additionally, the extra modelling tools can also be used in conjunction with PartMaker’s Full Machine Simulation module to design machine components includes turrets, gang slides or custom tool holders.

“The PowerSHAPE Companion for PartMaker will help PartMaker users be more capable in a competitive global manufacturing environment,” according to Hanan Fishman, President of the PartMaker Division of Delcam Plc. “This new product gives our users the ability to better meet their customers’ ever-increasing engineering demands and will allow them to manufacture more sophisticated and complicated parts in a more cost-effective manner. Being able to undertake file repair and other modelling tasks on the shop floor gives extra capabilities to PartMaker users that can both make them more productive and minimize machine down time.”

“As this new product is based on Delcam’s PowerSHAPE design product, it is easily the most capable 3D-design product being offered in conjunction with a PC-based CAM system on the market today. It will be supported directly by PartMaker’s industry-leading support team, providing users a single source of support for their engineering and manufacturing needs,” added Mr. Fishman.

Related Content

Tips for Tackling Mold Design, Machining, Cutting Tool and Wear Challenges

Tips for tasks ranging from reducing risk in part design and taking advantage of five-axis machining to refining cutting tool performance and reducing wear with guiding and centering systems.

Read MoreThe In's and Out's of Ballbar Calibration

This machine tool diagnostic device allows the detection of errors noticeable only while machine tools are in motion.

Read MoreLeading Mold Manufacturers Share Best Practices for Improving Efficiency

Precise Tooling Solutions, X-Cell Tool and Mold, M&M Tool and Mold, Ameritech Die & Mold, and Cavalier Tool & Manufacturing, sit down for a fast-paced Q&A focused on strategies for improving efficiencies across their operations.

Read MoreHow to Manage Wall Thickness Changes in Your Mold Design

To ensure even filling and cooling, consider wall section transitions, corners and fillets, ribs and bosses, lip and rim designs and CAE flow simulation software.

Read MoreRead Next

Reasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More

_300x250 3.png;maxWidth=300;quality=90)