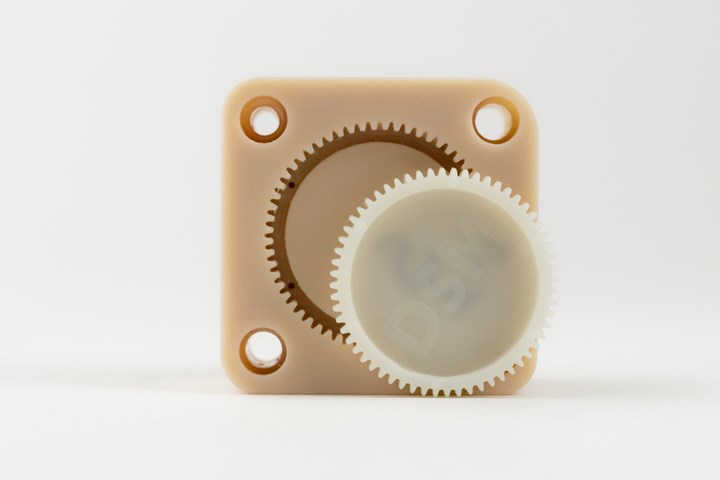

Industrial 3D Printing Solution Proves Rapid Injection Mold Tooling Production Capacity

Covestro DLP resin e-PerFORM used with EnvisionTEC’s Perfactory P4K series DLP 3D printing demonstrates faster, more cost-effective print speeds with high stiffness, high temperature performance.

Photo Credit: Covestro, EnvisionTEC

EnvisionTEC (Dearborn, Mich., U.S.), a wholly owned subsidiary of Desktop Metal, and polymer company Covestro AG (Leverkusen, Germany) have combined Covestro’s new DLP resin e-PerFORM and EnvisionTEC’s Perfactory P4K series printer technology for a complete industrial manufacturing solution for rapid, cost-effective 3D printing of injection mold tooling.

EnvisionTEC says it tested the e-PerFORM resin with key molding institutes to validate the material’s performance. Completed mold trials demonstrate that e-PerFORM resin, with high stiffness and high temperature performance, behaves similarly to stereolithography resin Somos PerFORM for injection molding tooling.

Further tests performed by Polyvia, the French Federation of Plastics and Composites, are said to have confirmed the suitability for rapid tooling, including good results in part fidelity and in the number of shots molded in both polypropylene and glass-reinforced nylon.

Related Content

-

MoldMaking Technology's Most-Viewed Content 2022: Products

MMT shares the five top-viewed technologies, equipment and services of 2022 in each Engineer, Build, Maintain and Manage tenet based on Google Analytics.

-

Evaluating Metal Powders for Conformally Cooled Mold Inserts

Mechanical properties and design software techniques reveal the benefits of a modified high thermal conductivity metal powder for 3D printing in moldmaking.

-

MMT Chats: 4 Keys to a Successful Mold-Building Operation: Innovation, Transparency, Accessibility and Relationship

MoldMaking Technology Editorial Director Christina Fuges chats with Steve Michon, co-owner of Zero Tolerance in Clinton Township, Michigan, about the excitement of solving problems, the benefits of showing gratitude, the real struggle with delegation and the importance of staying on top of technology. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

.png;maxWidth=300;quality=90)

_300x250 1.png;maxWidth=300;quality=90)