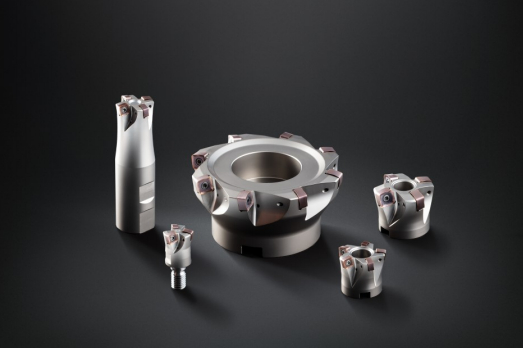

Horn USA's DAH8 High-Feed Milling System Facilitates High Chip Volume

Amerimold 2021 exhibitor presents next-generation DAH82 and DAH84 systems ensures a smooth, soft cut combined with good chip removal.

Photo Credit: Horn USA Inc.

Horn USA Inc. will be presenting its new development for high-feed milling, including the next-generation DAH82 and DAH84 systems, at Amerimold 2021. According to the company, the precision-sintered insert has eight usable cutting edges, resulting in a low cost per edge and a high level of cost-effectiveness. Despite the negative mounting position, the positive cutting geometry ensures a smooth, soft cut combined with good chip removal. Horn offers the inserts in the substrate SA4B, which is suitable for universal use in various materials. The large radius on the main cutting edge of the indexable insert also results in a soft cut, ensures even distribution of the cutting forces and extends the tool life. Maximum cutting depths supported are ap = 1.0 mm (DAH82) and ap = 1.5 mm (DAH84).

The DAH82 variant is available as an end mill and screw-in milling cutter with the following cutting edge diameters: 20 mm (z=2), 25 mm (z=3), 32 mm (z=4), 35 mm (z=4) and 40 mm (z=5). As an arbor milling cutter, it is available with cutting edge diameters of 40 mm (z=5), 42 mm (z=5) and 50 mm (z=6). For cutting edge diameters in excess of 50 mm, the larger DAH84 indexable insert is used. This can be supplied as an arbor milling cuter with the following standard diameters: 50 mm (z=4), 52 mm (z=4), 63 mm (z=5), 66 mm (z=5), 80 mm (z=6), 85 mm (z=6), 100 mm (z=7) and 125 mm (z=8). All tool bodies receive a special surface treatment for high strength and hardness, thus providing long-term protection against abrasive wear from chips.

Exhibitor: Horn USA Inc.

Booth 435 (P)

Related Content

-

Three Ways to Accurately Machine Hardened Mold Materials

Three cutting tool design considerations to improve process reliability and cost efficiency when deep-hole drilling molds.

-

Cutting Tools: Technology to Make Your Process Easier

Having the right cutting tool technology for moldmaking is a crucial component for efficiency and cost-effectiveness.

-

Treatment and Disposal of Used Metalworking Fluids

With greater emphasis on fluid longevity and fluid recycling, it is important to remember that water-based metalworking fluids are “consumable” and have a finite life.

.png;maxWidth=300;quality=90)

_300x250 3.png;maxWidth=300;quality=90)