Electric Servo Cylinder Enables Detailed Valve Pin Control, Energy Efficiency

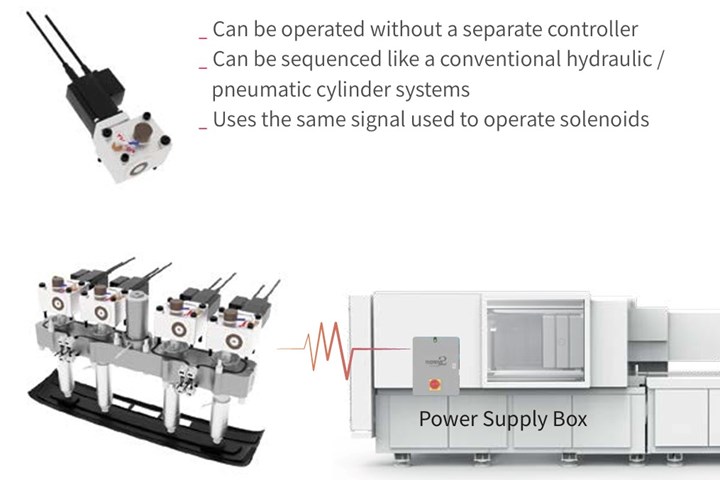

NPE2024: Yudo USA features Yu Drive II Eco, a compact solution that doesn’t require a separate controller, operating only by combining injection machine signals.

Yudo USA features the Yu Drive II Eco electric servo cylinder. Its electric valve pin control enables more delicate, individual control of the valve pins in a compact setting using only the signal from the injection molding machine, potentially solving a wide range of challenges that can occur during production.

Use of the Yu Drive II Eco reduces the cost of Capex due to the input signal that comes from the molding machine and eliminates the need for an external controller. Moreover, the solution has a finite amount of settings, making setup quick and easy. Seven total configurations are possible.

Yu Drive II Eco can be sequenced like conventional hydraulic/pneumatic cylinder systems. It uses the same 24 VDC signal used to operate solenoids. Importantly, Yu Drive II Eco consumes less energy than a typical hydraulic cylinder, adding to its more eco-friendly nature.

The company notes that sustainability has been a trend it continues to pursue, whether it’s through the electric servo cylinder, or hot runner systems and components that perform well with eco-friendly recycled resins. Yudo looks forward to working with customers on their new projects.

Related Content

-

Mold Builder Invests in Five-Axis Milling to Open the Envelope

NPE2024: Mold-Tech Inc., dedicated to complete quality and support, continues to add to its hard milling equipment department with the Makino D200Z, enhancing mold lead times, accuracy and efficiency.

-

Educating the Next Generation of Plastics Professionals

These schools and local industry are working together to close the workforce gap in the plastics industry by offering hefty plastics curricula and training programs for degree-seeking students as well as current plastics employees looking to upskill.

-

Use AI, Machine Learning to Take Variability Out of Manufacturing

Variability has always created insurmountable challenges for manufacturers. However, in the last decade, impact has been more painful due to a lack of experienced workforce. By leveraging technological advancements, particularly in AI, manufacturers can gain a transformative competitive advantage in both cost reduction and workforce development.

.png;maxWidth=300;quality=90)

_300x250 3.png;maxWidth=300;quality=90)