Die and Mold Carbide End Mills Have Coating for Better Wear

RobbJack has many product lines at Amerimold 2018.

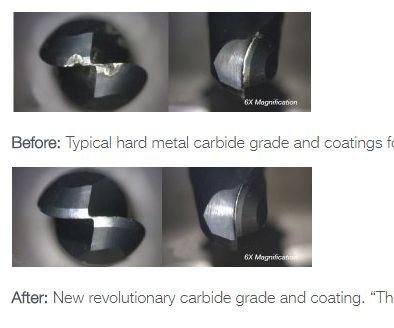

RobbJack features many product lines at Amerimold 2018. Among the numerous tools company displays, the highlight of the show is its die/mold series end mills. The company says that the DM/MDM die/mold carbide end mills are made with a revolutionary coating technology, reduce wear by 909 percent and last over 450 percent longer than comparable tools in hard metal applications. RobbJack says that the DM/MDM die/mold carbide end mill offers tighter tolerances, lasts longer in difficult areas like parting lines and produces better finishes that reduce or eliminate the need for polishing. According to RobbJack, when tests were conducted in D2 58 HRc that pitted comparable carbides and coatings against RobbJack’s DM/MDM die/mold carbide end mills, RobbJack’s tools outperformed every test tool with a smooth wear land of only .0025", which is 909 percent less wear.

Related Content

-

MoldMaking Technology's Leadtime Leader Awards Competition Returns!

After a brief hiatus, MoldMaking Technology’s Leadtime Leader Awards Competition is back!

-

More Than Moldmaking at PTXPO 2023

The Moldmaking Pavilion returns to the Plastics Technology Expo (PTXPO) March 28-30, 2023, at the Donald E. Stephens Convention Center in Rosemont, Illinois, but there’s more to discover than moldmaking.

-

Where Mold Manufacturing and Plastics Processing Connect

The Moldmaking Pavilion is one of seven pavilions returning to the show that houses exhibitors offering technology and service solutions for your specific moldmaking needs.

.png;maxWidth=300;quality=90)