VasanthaTech Establishes US Operations in Cincinnati

Division of India-based Vasantha Group will focus on moldmaking for the medical and packaging markets.

Hyderabad, India-based Vasantha Group has opened a facility in West Chester, Ohio, to expand the company’s global operations and establish a foothold in North America. VasanthaTech, the name of Vasantha Group’s new U.S. operations, will focus on serving the company’s core strength of building high-cavitation, high-precision molds for the medical and packaging markets.

Varun Reddy, director of sales and foreign operations for Vasantha Group, says the company has made the move to the U.S. to bring its highly technical moldmaking expertise to North America. The company boasts 650 employees worldwide.

“We made the decision to expand to the USA in 2019,” says Reddy. “We hired a few key employees to start the process, and since then we’ve invested over $7 million to acquire a facility, machinery and more. We are now ready to move forward building our business in North America.”

After the initial $7 million outlay to start the business, Vasantha plans to invest another $15 million to grow the North American business over the next five years. Reddy anticipates having up to 60 employees working at this facility by 2028.

Industry veteran Shawn Schnee is CEO of VasanthaTech. He joined the company after working as manager of advanced engineering at iMFLUX, a plastic injection molder; prior to that he was manufacturing technical specialist at healthcare giant Ethicon Inc. “We have 20 people here now, but this is just the beginning for us,” Schnee says.

Stocking up on machinery, equipment

The VasanthaTech West Chester facility has four new Fanuc Roboshot molding machines coming in July, which will help the company run trials on larger molds. The new machines will be 180, 220, 300 and 450 metric tons. They will join two Arburg machines that the company has for running liquid silicone rubbr (LSR) and micromolding applications. A new Class 8 cleanroom for medical molding applications is also coming this summer.

Andrew Cummings, sales manager for VasanthaTech, joined the company in January 2023 after working in top sales and product management roles at Mold-Masters Ltd. and Zahoransky Automation & Molds. He says the value that Vasantha’s new U.S. facility provides customers includes the ability to run mold trials and provide complete customer support for Vasantha molds, right here in the U.S.

“Cincinnati is a great location for us and our customers,” Cummings explains. “We build development and pilot molds here, typically one or two cavity tools, to prove the concepts; then the high-cavitation production tools are built in Austria or India. The finished molds are shipped to our Cincinnati location, where customers can visit to see them for trials before they ship to their destination. All [of] our customer support and mold trialing for our customers takes place at our Cincinnati location.”

In addition, VasanthaTech handles all the logistics of working with the Austria and India locations to manage the project and have the finished mold shipped to the U.S. “We make it as easy as possible for our customers to get their molds delivered from overseas,” Cummings says. “It can save them a lot of time and hassle.”

VasanthaTech will be exhibiting at NPE 2024.

Growing automation ventures

Most recently, Vasantha Group has started a new automation venture, Savya Automation, with locations in both India and Austria. Savya will provide full-scale injection molding automation, including end-of-arm-tools (EOATs) and applications including part handling, transport, sorting, boxing, etc. “Savya has been added to achieve our goal of providing turnkey solutions, with Vasantha taking full responsibility for a project in its entire scope,” says Manfred Schinko, CEO of Savya Automation and VTW.

Vasantha’s VTW operation in Austria was formed from former KTW employees, a division of Husky. When Husky proposed shutting down the facility, the employees found Vasantha Group as an investor, which they then invested €20 million into a new facility in 2020 and named the company VTW GmbH which resides in Waidhofen/Thaya, Austria.

V+ Solutions is Vasantha’s engineering hub, based in Freiburg, Germany. Led by Michael Schmidt, V+ provides complete engineering support for Vasantha’s customers worldwide, said to design the most innovative production solutions that optimize production. Schmidt joined Vasantha in 2022 after a long career at Zahoransky Automation & Molds GmbH, where he was managing director of sales.

Read Next

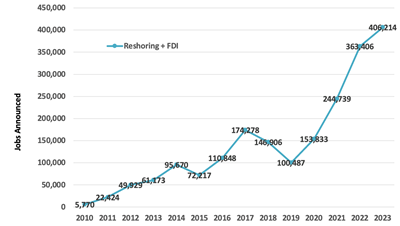

US Reshoring Reaches Another All-Time High

According to the Reshoring Initiative Q1 2023 data report, manufacturing job announcements continue to outpace recent records, which could accelerate further should a true industrial policy be implemented.

Read MoreMoldMaking and Molding Conference Sessions Finalized

August 29-30 in Minneapolis all things moldmaking and injection molding will be happening at the Hyatt Regency — check out our speakers and topics!

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More

.png;maxWidth=300;quality=90)