R&D Leverage Europe to Offer Injection Blow Mold and Tooling Development

Investment in equipment for mold validation and sampling, a second Product Solutions Lab and enhancement of technical team expands R&D’s IBM services.

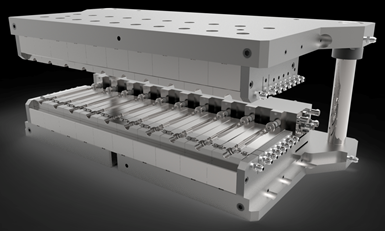

R&D Leverage Europe, a subsidiary of moldmaker Adler Industrial Solutions, has announced a significant expansion in its services with the addition of injection blow mold (IBM) capabilities. In 2023, the company has invested substantially in equipment and infrastructure to facilitate this development, including the purchase of IBM machines for mold validation and sampling.

This extension of capabilities marks a transformative moment for R&D Leverage Europe as it positions itself as a comprehensive solution provider in the IBM sector. With an unwavering commitment to innovation and customer satisfaction, the company sees potential within this demanding market segment.

In anticipation of the increased demand for its services, R&D Leverage Europe will expand its technical team via numbers and expertise through intensive training. This strategic move will help the company ensure it remains at the forefront of IBM technology and is well-equipped to deliver cutting-edge solutions, to existing and new customers.

Employing more than 80 dedicated professionals, R&D Leverage Europe operates from state-of-the-art facilities on its campus in Ashfield, Nottinghamshire, England, with a total area of 40,000 square feet. As part of its expansion plans, the company is actively developing an adjacent 15,000-square-foot facility to house a second Product Solutions Lab, initially housing two mold validation machines for the IBM sector.

For inquiries and more information about the company's expanded services, please contact info@rdleverage.com