Kubotek Updates Kosmos 3D Framework

Building engineering software has been made more streamlined with version 3.0 of Kubotek’s Kosmos 3D Framework, a set of advanced, multi-platform software components.

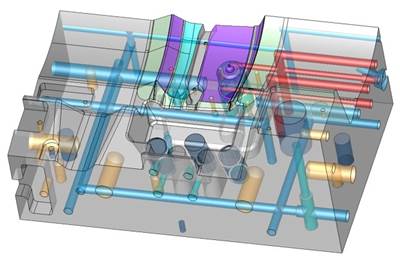

Example of automatic detection of local features (highlighted in red) in an imported B-Rep solid. Photo Credit: Kubotek

Kubotek3D (Marlborough, Massachusetts) developer of 3D mechanical computer-aided design (MCAD) software, announced on Dec. 2 that the Kubotek Kosmos 3D Framework has been updated to version 3.0. The framework, with the new update, is said to be a set of advanced, multi-platform software components which maximizes a program’s performance and ability to work with complete engineering models and data from all major MCAD databases. According to the company, the Kubotek Kosmos 3D Framework supports software developers building precise 3D applications which need to work with engineering models and data.

“We’ve seen steady performance gains with use of Kubotek technology in our applications,” claims Ed Freniere, president at Lambda Research Corporation. “The Kosmos framework has also improved our ability to reliably import complex geometry.”

The Kubotek Kosmos 3D framework, for example, now provides support for reading engineering models and data from more than a dozen major file formats. For the 3.0 release, the framework has expanded its support of STEP files.

This includes added read and write support for STEP AP 242 Model-based Definition (MBD) data. STEP AP 242 is an ISO standard that defines precise 3D models as well as critical manufacturing annotations including Geometric Dimensioning and Tolerancing (GD&T) and their relationship to the faces of the model. This form of MBD can provide process efficiency by eliminating the need to translate the design into detail drawings and better support automation of downstream activities such as NC machining and inspection.

Read and write of compressed ASCII STEP files which use the extension “.stpZ” have also been added to the software, a format that Kubotek says has been gaining in popularity, especially in the aerospace and automotive industries. Compressed STEP files are around 20% of the size of uncompressed STEP files.

According to the company, Kubotek Kosmos also stands out from other 3D modelers in the performance department due to its unconstricted support for multi-threaded processing. For the 3.0 release additional areas of the code have been further optimized:

- Feature recognition

- Surface/Surface Intersection

- Booleans

- Faceting

- Multi-threading in additional file readers

- Transforming assemblies.

Automatic geometric feature recognition such as machined holes, fillets/rounds and chamfers is another core feature of Kubotek’s software. The following capabilities have been improved:

- Identifying blend/chamfer/rib/slot/boss/pocket features in sheet bodies

- Improved vertex blend recognitions

- Improved blend features with cliff edges

- Improved blend features for surfaces with poles

- Improved blend boundary conversion

- Improved the connecting conditions between blends of a feature

- Improved ruled surface detection for chamfer.

Finally, Kubotek says the framework fully supports development of applications to run on numerous platforms. A Python wrapper has been added to allow teams developing in the high-level Python programming language to quickly integrate Kubotek Kosmos with existing code. Further, a new Text library was introduced, which works with the graphics component for improved support for displaying text objects within the 3D scene, as well as an updated compiler support to include MSVC 2019.

“Our development team has continued to expand and refine the Kubotek Kosmos framework in many important areas,” says Ram Eswaran, CTO/COO of Kubotek3D. “This year our proprietary STEP translation capabilities have improved to support MBD initiatives in manufacturing supply chains with critical feature, tolerance and surface finish details.”

Related Content

Four Micro Tooling Considerations

Issues involving gating, ejection, mold splits and direction of pull are of special concern when it comes to micro tooling.

Read MorePlastic Injection Molding Starts with the Pellet

This summer, let’s get back to the basics. For this summer school basics series, Pellet to Part explores each stage of the plastic injection molding process. This week: what every moldmaker should know about raw materials, including the fundamentals of viscosity curves, Melt Flow Index, Melt Flow Rate, shear and more.

Read MoreWhat Is Scientific Maintenance? Part 1

How to create a scientific maintenance plan based on a toolroom’s current data collection and usage.

Read MoreIt Starts With the Part: A Plastic Part Checklist Ensures Good Mold Design

All successful mold build projects start with examining the part to be molded to ensure it is moldable and will meet the customers' production objectives.

Read MoreRead Next

3D CAD Software Release Ensures Manufacturing Agility and Efficiency

Enhanced model-based definition capabilities including improved color tools, expanded proprietary readers for STEP files and more round out Kubotek3D’s KeyCreator MfgCAD software.

Read MoreYour Guide to Smarter, Faster Mold Design

Dive into expert-curated content delivering proven solutions for mold optimization, manufacturability and precision performance.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More