Additive Manufacturing Users Group Announces Keynote Speakers

Dr. Mike North, Jason Lopes and Todd Grimm to set conference tone.

The Additive Manufacturing Users Group (AMUG) today announced its featured keynote speakers for its 2014 Education & Training Conference, which will be held in Tucson, Arizona, from April 6 – 10, 2014. Dr. Mike North, Jason Lopes and Todd Grimm will inform, motivate and excite attendees with their discussions of additive manufacturing possibilities.

Bret Bordner, AMUG president, said, “We are extremely pleased to have three well-known, well-respected keynote speakers to kick off our daily activities. Each of these speakers has interesting, insightful information to share, and each presents in an engaging way that will energize attendees for the day to come.”

Todd Grimm, president of T. A. Grimm & Associates and AMUG’s AM industry advisor, will open the event with what he calls an enthusiastically realistic look at the 3D printing industry. On Monday, April 7th, he will jump start the conference with insight into the big picture for additive manufacturing. He will share his thoughts on the present and future with highlights of recent developments, current trends and future advancements. This will be Grimm’s fourth appearance as an AMUG keynote speaker.

Back by popular demand, Jason Lopes of Legacy Effects will open day two with a ‘backstage’ look at additive manufacturing’s role in feature films and commercials. Lopes will ignite imaginations on Tuesday, April 8th, with a visual journey of Legacy Effects’ additive manufacturing solutions that enable director’s visions to come to life. Lopes’ film credits include Avatar, Terminator Salvation, Alice in Wonderland, Ironman 1, 2 & 3, Avengers 1 & 2, Robocop and Pacific Rim.

Dr. Mike North, founder and chair of Reallocate and founder of North Design Labs, will step to the stage on Thursday, April 10th. In his presentation, Additive Manufacturing, A Force for Good, he will discuss how the technology has the power to transform the world. He will share real world examples of how additive manufacturing is creating positive impact and give a glance into the future of using it for good. North’s message draws on his first-hand experiences at Reallocate, which is an organization that connects world-class talent to social impact projects to create real-world solutions. Many will recognize North from his role in the Discovery Channel’s Prototype This!

Following the keynote presentations there will be hands-on workshops and presentations that cover art & architecture, metal casting, education, manufacturing tools, materials, medical, direct metals, scanning, stereolithography, laser sintering and transportations.

“We have organized a great conference with a cross-platform agenda to meet the needs of all AMUG members technical expertise,” said Bordner.

The users group conference, now in its 26th year, is open to owners and operators of all additive manufacturing (3D printing) technologies. The advanced, all-inclusive conference registration fee is $695.00. For details and a link to registration, visit www.am-ug.com.

AMUG is an organization that educates and advances the uses and applications of additive manufacturing technologies. AMUG members include all commercial additive manufacturing/3D printing technologies for companies such as 3D Systems, Stratasys, ExOne, Concept Laser, Renishaw, SLM Solution and voxlejet. AMUG meets annually to provide education and training through technical presentations on processes and new technologies. This information addresses operation of additive manufacturing equipment and the applications that use the parts they make. Online at www.am-ug.com.

Related Content

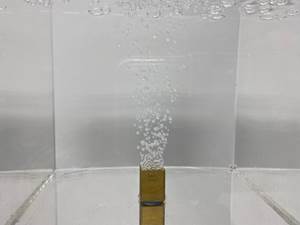

VIDEO: How can 3D Printed Tooling Improve Injection Mold Venting?

Proper venting is one of a mold builders toughest challenges as molders struggle to keep vents free flowing in production. Learn how to apply 3D printing to mold venting and the benefits of additive venting inserts.

Read MoreMMT Chats: 4 Keys to a Successful Mold-Building Operation: Innovation, Transparency, Accessibility and Relationship

MoldMaking Technology Editorial Director Christina Fuges chats with Steve Michon, co-owner of Zero Tolerance in Clinton Township, Michigan, about the excitement of solving problems, the benefits of showing gratitude, the real struggle with delegation and the importance of staying on top of technology. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

Read MoreVariable Density-Coated Tool Steel for High-Wear Molds

A mold builder can have an abundance of venting and fully dense solid areas in steel by using variable density sintering to eliminate gas trap defects in high-wear molds.

Read MoreThe Benefits of Vertically Integrating Metal 3D Printing and Machining

Having 3D printing and machining within one organization enables Addman’s engineers to collaborate and consolidate so it can quickly make successful metal 3D-printed parts.

Read MoreRead Next

How to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More

_300x250 3.png;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)