Case Study

ERP Empowers Mold Builder to Increase Speed, Efficiency, Accuracy

Highly integrated but easy-to-use ERP system helps Delta Mold Inc. increase unattended hours, uptime, productive labor hours and improve mold delivery times.

Peggy Malnati

Contributing Writer, MMT

CAD/CAM Software Reduces Delivery Times by 70% With a Six-Month ROI

Single integrated CAD/CAM package reduces translation errors, simplifies design process, improves shop efficiency and shortens tool lead times.

Read MoreMachine Monitoring Platform Improves Machine Utilization, On-Time Delivery

Using data from a machine monitoring platform, Westminster Tool added almost 75 hours of capacity per week by shortening warmups and starting CNC and EDM machines sooner.

Read More3D Scanning Quickly Solves Tool Repair Problems

3D scanning supports the repair of molds with no history, drawings or design files.

Read MoreLaser Welding Repairs Micro-Threaded Inserts Fast

Moldmaker/molder Medbio LLC sent unscrewing cores with damaged micro-threads out for repair via laser welding and polishing, slashing nine weeks off lead time to produce new inserts.

Read MoreUsing CT Scanning to Qualify Molds Faster

Software and hardware advances reduce dimensional inspection with part-to-CAD by 70%.

Read MoreFive-Axis Vertical Mill Increases Mold Shop Capacity by Reducing Setups

Zero Tolerance now processes blocks — from squaring to waterline drilling to rough and finish milling — on a single five-axis CNC mill, reducing setups and moving blocks in/out of multiple machines without sacrificing accuracy and surface finish.

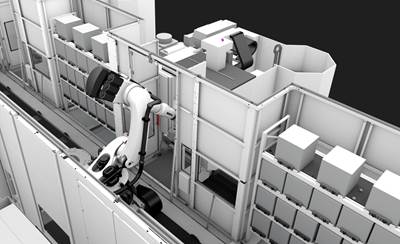

Read MoreUsing Automation to Reduce COGS and Stay Globally Competitive

Decade-long, multiphase automation investments lower operating costs and maintain technology lead in an increasingly competitive global market.

Peggy Malnati

Contributing Writer, MMT

CAM Automation Increases Mold Production, Quality

Mold builder switches CAM software package after 20 years to take advantage of innovative programming strategies that reduce mold machining programming and processing times.

Read MoreMold Builder Meets Increased Domestic Demand With Automated Cells

Burteck LLC experienced significant demand increases due to reshoring and invested in automated machining cells to step up its production output quickly and avoid losing business.

Read MoreFive-Axis Machine With Pallet Changer, 16k-Spindle, Versatile Control Makes More Accurate Molds Faster

The move from three- to five-axis machining with automation reduced setup times and improved surface finishes for this small but mighty Amish mold builder.

Read MoreLarge Hybrid Steel Insert Solves Deformation, Dimensionality, Cycle Time Problems

DMLS printers using metal additive powders selected by Linear AMS to produce high-quality, accurate, consistent 3D-printed mold components with certification and traceability.

Read MoreTrue Five-Axis Machine Yields More Throughput, Greater Productivity

CDM Tool & Mfg. Co. LLC increased shop capacity thanks to a versatile high-speed/high-accuracy five-axis Fooke mill capable of cutting very large workpieces quickly and accurately with fewer setups.

Read MoreCT Scanning Helps Micro Molder Reduce Cost of First Article Inspections

CT scanning services performed by 3D ProScan, a division of NyproMold Inc. provides MTD Micro Molding with accurate, high-resolution internal and external measurements performed about seven times faster and at significant cost savings.

Read MoreMold Builder Uses Metal 3D Printing to Bridge Medical Product Development to Production

Westminster Tool uses metal additive manufacturing for medical device OEM, taking lessons learned from R&D in the prototype mold phase to full-scale production molding in a fraction of the time.

Five-Axis Graphite Mill With Automation Debottlenecks Electrode Machining

Five-axis electrode cutting enabled Preferred Tool to EDM complex internal screw geometry on an insert that otherwise would have had to be outsourced.

Read MorePrecision Welding Services Offer Rapid Turnaround Mold Repair and Reduced Molder Downtime

X-Cell Tool & Mold relies on outsourced, high-quality welding repairs from Lewis-Bawol Welding to ensure its customers' molds are back in production quickly and affordably.

Read MoreThe Trifecta of Competitive Toolmaking

Process, technology and people form the foundations of the business philosophy in place at Eifel Mold & Engineering.

Read MoreThe In's and Out's of Ballbar Calibration

This machine tool diagnostic device allows the detection of errors noticeable only while machine tools are in motion.

Read MoreOEE Monitoring System Addresses Root Cause of Machine Downtime

Unique sensor and patent-pending algorithm of the Amper machine analytics system measures current draw to quickly and inexpensively inform manufacturers which machines are down and why.

Read MoreFrom Machining Centers to Cutting Tools: Here are the Top Ten Case Studies from 2022

MMT publishes monthly case studies that present a shop’s problem, solution and results in thorough detail. Take a look at the top ten most popular case studies published in 2022 based on Google Analytics.

Read MoreExtensive Evaluations Build The Plastek Group’s EDM Arsenal

Sinker and wire EDMs selected for speed, volumetric accuracy, surface finish, reliability, cost of ownership and extensive warranty.

Peggy Malnati

Contributing Writer, MMT

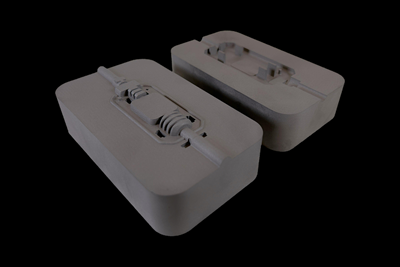

Multi-cavity Hot Runner Design Takes on Bio-based Material Challenges

Mold builder teams up with a hot runner supplier to develop a system configuration that produces an eco-friendly, attractive single-serving capsule.

Read MoreAdvances in P20 Steel Potentially Eliminates Need for Stress Relieving After Rough Cutting

Omega Tool Corp. compares conventional, new P20 grades side by side in production fascia tools, finds no downside.

Read MoreReducing Cutter Breakage When Micro Machining Hard Mold Material

A new micro drill increases productivity when making highly precise holes in hard mold steels.

Read MoreHybrid Milling/Drilling Machine Reduces Total Mold Machining Time

MSI Mold Builders now squares, plus drills and taps eye-bolt holes on 50% of its tools in a single setup using a five-axis milling/drilling center with a universal spindle.

Read MoreModular, Flexible CAM Speeds Five-Axis Programming, Boosts Profitability for Moldmaker

P and C Tool improves mold quality, minimizes secondary processes, takes on new business opportunities and increases profitability with new integrated CAM software.

Read MoreWomen Impacting Moldmaking

Honoring female makers, innovators and leaders who are influencing our industry's future.

Read More

_300x250 3.png;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)

_970x250 3.png;maxWidth=970;quality=90)

.jpg;maxWidth=300;quality=90)