Hot Runners for Technical Part Molding with Engineered Resins

See Us at amerimold Booth 617 and Register Today!

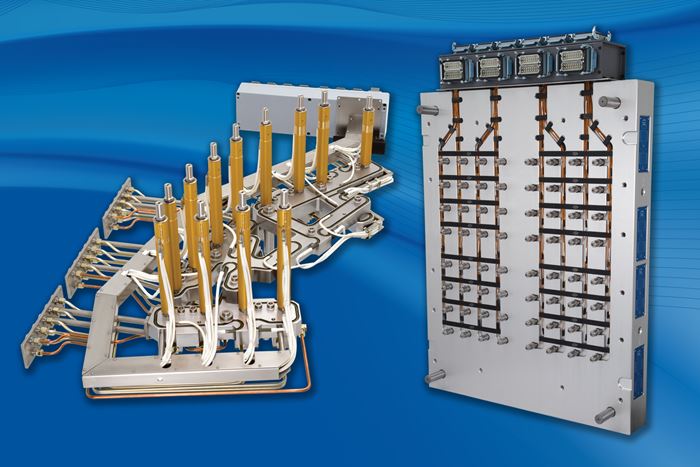

DIRECT-FLO™ (DF) Gold hot runners.

INCOE® (Troy, MI) offers its line of DIRECT-FLO™ (DF) Gold hot runners, designed for technical part molding with engineered resins. With shot weights up to 9000g, DF systems are ideal for automotive, appliances, electronics/technical, housewares and medical device parts. Standard system features offer the widest range of gating options with unitized leak-proof designs.

QUICK-FLO™ (QF) systems are used with commodity grade resins for caps and closures, medical disposables and pharmaceutical packaging applications which demand maximum output, repeatable part quality and superior cosmetics. With up to 375g shot weight capacity, complete hot half systems are included.

Both systems are available with OPTI-FLO® rheologically balanced manifolds featuring Beaumont Technologies Inc. patented MelfFlipper® technology which can provide improved cycle times and processing capability.

Related Content

-

Considerations for Mold Base Material Selection

Choosing the right material can greatly affect the profitability and cost of your application.

-

Treatment and Disposal of Used Metalworking Fluids

With greater emphasis on fluid longevity and fluid recycling, it is important to remember that water-based metalworking fluids are “consumable” and have a finite life.

-

Maintaining a Wire EDM Machine

To achieve the ultimate capability and level of productivity from your wire EDM on a consistent, repeatable and reliable basis, regular maintenance is a required task.

.jpg;maxWidth=970;quality=90)

.jpg;maxWidth=600)

_300x250 4.png;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)