5 High-Volume Machining Trends at IMTS 2022

Manufacturing businesses that machine parts in high volume are looking to new technology — hardware and software — to become more competitive.

Machine shops producing parts in high volumes face challenges that low-volume operations might not encounter.

It’s one thing for a machine shop to make a few good parts for a given job, but it’s another to consistently and repeatedly make hundreds of thousands of the same good parts. Process control becomes a bigger deal to eliminate scads of scrap or parts that need to be reworked. What follows are five trends I have noticed that are on the minds of owners and managers of production machine shops as they look to IMTS this fall. Some of these reflect the notion that “machine shop” is no longer a valid description for manufacturers with machining capability:

High-production machines are becoming more flexible.

- Rotary transfer machines, multispindles and Swiss-type lathes are common platforms for high-volume machining. While part-volume requirements for production shops remain high, flexibility to pivot to different jobs is becoming more important. Builders of high-production machining equipment have recognized this trend and are modifying machine designs accordingly to be more versatile.

Automation is more than robots.

- Robots are now more flexible, easier to program and, in some cases, re-deployable to various pieces of equipment. However, shops are also looking at more equipment such as tool presetters, on-machine part and tool probing and automatic toolchangers for B-axis Swiss-types as a way to eliminate manual tasks (and the risk of error) from the machining process.

More efficient measurement/inspection processes are needed.

- Lights-out machining enables shops to get the most value out of their equipment and employees. But that often means there are many parts in the queue to be inspected. Part measurement can become an early-morning bottleneck that soaks up shopfloor workers’ valuable time. This has shops looking to new measurement technology that can speed and simplify part measurement (vision systems, for example).

Focus is shifting from hardware to software.

- Basic physics means machine tools have effectively hit the ceiling in terms of how fast they can remove material, their spindles can rotate, their tables can move and so on. However, this has machine shops looking more to software to boost overall process efficiencies. More capable and intuitive enterprise resource planning (ERP) software is becoming a big a part of this. But so is the ability to more easily pull data from machines, a benefit from sensor technology to enable more adaptive machining, perform statistical process analysis and more.

More processes are being brought in house.

- These days, production manufacturers are looking to be one-stop-shops for their customers. That has them eyeing processes and equipment that can enable them to machine, finish, clean, assemble, package and perhaps even manage inventory for customers. One process example is passivation. For stainless steel parts, passivation is often required to remove any free iron from the part surface, while leaving behind a protective coating. In the past, this was often outsourced because the prevalent method used nitric acid, which is terribly corrosive. Shops didn’t want to jump through EPA hoops or bring such a toxic chemical inside their facility as it could corrode their equipment. Today, though, citric passivation is becoming more widely accepted, especially in the medical industry. This process is as corrosive as orange juice, making it more enticing to bring in house.

Related Content

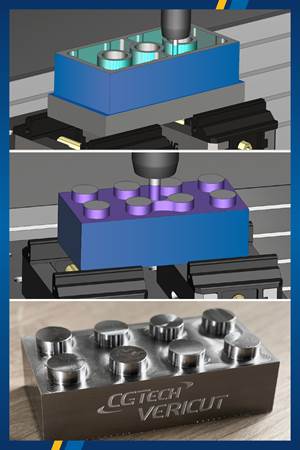

Building Blocks and Partnerships

Attendees can experience a variety of live demonstrations, as well as toolpath optimization, machine monitoring and connectivity demos and more as they work their way through the Controls and CAD/CAM and Machine Tool halls where Vericut is being highlighted.

Read MorePrecision Handheld 3D Scanner Delivers Fast Digitization for Large and Small Molds

Capture 3D is bringing the Zeiss T-Scan hawk to IMTS 2022, which can rapidly collects precision 3D measurement data in place.

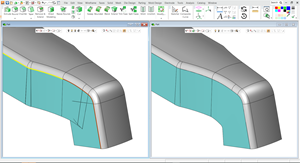

Read MoreCAD/CAM Software Equips Moldmakers with New Features, Functions

Cimatron v16 introduces new and enhanced capabilities to equip toolmakers across the spectrum to deliver high-quality tools faster and easier.

Read MoreTake a Spin Where Speed Matters

IMTS22: NSK America Corporation showcases hand tools, spindles and a play table of technology that offers hands-on learning.

Read MoreRead Next

How to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More

.png;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)

_300x250 4.png;maxWidth=300;quality=90)

_970x250 1.png;maxWidth=970;quality=90)