Mold Repair: Laser Welding Delivers Lower Costs and Better Quality

Sponsored ContentWhile TIG (tungsten inert gas) welding may be the go-to for mold welding in many shops, high-power pulsed laser welding is a higher-quality process that can deliver repaired molds that perform like new.

Share

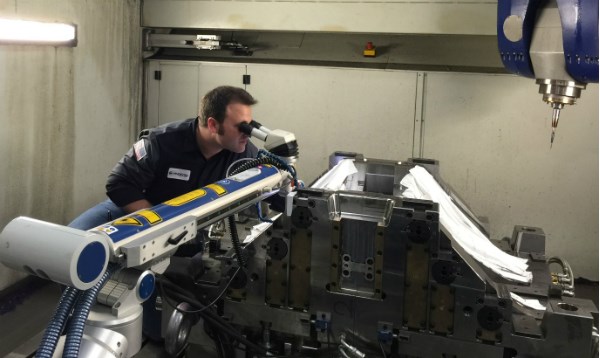

Portable laser welding technology lets users repair large tools anywhere, even right on a five-axis machining center.

Repairing a worn mold is always going to be cheaper than replacing it. The catch is how well that refurbished mold is going to perform in the future. Will it produce parts of equal quality to the original? How long will it last until it needs repair again or has to be scrapped?

For molds going to the welding repair shop, the quality of the welds and the welding process has everything to do with answering those questions. In the U.S., the most common practice to rebuild worn cavity and core surfaces is with TIG (tungsten inert gas) welding.

However, plastics processors will find that the alternative, pulsed laser welding, delivers a superior result with less damage to the base material, so the mold will produce better quality parts and last significantly longer after the repair.

To understand how pulsed laser welding works, we spoke with Blair Learn, president, and Wes Wheeler, sales manager, at Alpha Laser (Meadville, Pennsylvania). This company actually has two businesses; Alpha Laser-US is the U.S. arm of German laser manufacturer Alpha Laser GmbH, and the other, Phoenix Laser Solutions, specializes in laser welding as a service. Beyond selling lasers, these companies work with customers every day repairing molds, dies and other demanding parts.

The primary argument for pulsed laser welding over conventional TIG or micro TIG welding is that the laser delivers a higher quality end result because it does less collateral damage to adjacent areas of the weld (such as the heat-affected zone). With a conventional welding process, the material in that zone becomes softer and more likely to wear. Microcracks and/or porosity in the weld itself will result in poor surface quality and shortened life of the tool.

Besides of this primary advantage, other benefits of today’s laser welding technology include:

- Ability for molds to be repaired multiple times

- Quicker repair of molds with much faster machining or bench time

- Portable and flexible to reach almost any feature, even in large molds

- Less expensive from a total-cost perspective and lasts longer

Here’s how today’s pulsed laser welding technology enables all these benefits.

What Happens When You Weld

Let’s start basic. You send a mold out to a welding shop, for example, to rebuild a worn corner, fill a crack or hole, or repair a worn gate that is now generating flash. First, those areas of the mold will be built up or filled in by welding a bead of filler material onto the component surface. The features are then re-machined to blend the surfaces and restore the mold to its original dimensions.

With conventional TIG welding, electrical current is introduced to the workpiece surface and filler wire via an electrode that creates the “welding arc.” The welder holds the TIG torch in one hand and a wire of the filler material in the other and slowly moves across the repair zone with the arc melting the filler material to lay down the bead.

With pulsed laser welding, a very precise beam is aimed at the filler material as it is laid down. Besides being more accurate to position, the width of the beam is highly controllable, with Alpha’s welding lasers, between 0.2 and 2.0 mm in diameter.

The pulsing of the beam (typically about 5-30 pulses per second) allows very fine control of how much energy is being directed to the weld. The laser is directed in high-energy bursts that allow the welder to move at a higher speed without generating more heat than necessary. The pulsing also contributes to more rapid cooling of the workpiece.

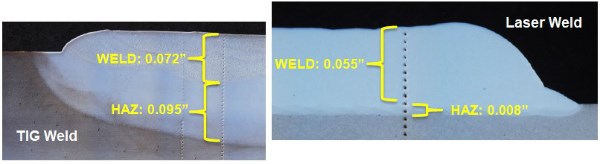

Laser welding is much more precise, and leaves a dramatically smaller

heat-affected zone (HAZ).

All of these factors help to substantially reduce the heat required to generate a quality weld. In fact, you can comfortably touch the workpiece immediately after laser welding. Don’t try that after conventional TIG welding.

This lower-heat process has a major impact on how a repaired mold will hold up over time because the metallurgical properties of the mold material are significantly altered in the heat affected zone (HAZ). High heat essentially anneals the metal, making it softer.

A typical TIG welding process softens the metal around the weld by about 10 to 15 points on the Rockwell hardness scale (RC). Given that tool steels for cores and cavities are typically hardened to about 30-60 RC (to increase wear resistance), that’s a 20-30% reduction in hardness. With pulsed laser welding, the softening is much lower, about 2 to 4 points RC.

Perhaps more importantly with pulsed laser technology, the heat-affected zone is much smaller. Conventional TIG welding will generate a HAZ almost 0.100" deep, while the pulsed laser generates only about 0.008".

That softened area of the mold is going to wear much quicker than it did in the original mold. Moreover, high heat can cause physical distortion of the metal, which may adversely affect delicate features in a precision cavity.

There also can be a problem with porosity within the weld itself. This may not be visible from the top of the finished weld, but it will be revealed once the area is machined. Molds repaired with laser and TIG welding may look the same to the naked eye. However, once you put those molds to the test of a repetitive injection molding process at 20,000 psi, the results will be very different over time.

Laser welding enables wide latitude of the use of materials. Here, 420 stainless steel is welded onto beryllium copper.

Powerful and Portable

Not all lasers are created equal, and Alpha agrees that the process received some criticism when it first emerged 20 years ago. Most of that, they contend, was because the lasers weren’t powerful enough for welding tool steels. An under-powered laser slows down the process, which replicates some of the same problems seen with conventional welding. This is why Alpha’s Nd:YAG welding lasers go up to 500 watts (W) versus the more typical 300 W found today, they say.

Another limitation of lasers early on was that they were a stationary pieces of equipment with relatively limited physical reach. That made laser welding impractical in many cases, particularly with large molds.

Two of Alpha’s laser models—the ALM and ALFlak models—exhibit just how much the technology has evolved.

With its extremely short setup times and mobility, the ALM laser welder allows large molds to be repaired anywhere. Just move the ALM laser welder into position, secure the laser area, aim the slim laser arm at the weld, and start welding. The hydraulic brakes fix the laser beam at exactly the desired work position, and if more flexibility is required, the laser head can be turned and tilted, allowing the user to move the laser beam up to 40 degrees from vertical to any direction. Welding can be done manually using a joystick, semi-automatically, or fully automatically with an external operating unit.

The larger ALFlak Max models can reach even more features from a single position with a laser arm that can extend over 9 feet long in the largest model. Still portable, these lasers can be driven by a self-propelled continuous track or moved manually. The ALFlak can lay down beads or seams over 19-1/2 inches (500 mm) in length from a single position.

This combination of portability, power and precision makes laser welding a good choice for almost any circumstance. For very large molds, you can bring the laser to the tool, even right on the press, yet still generate the most delicate features in a cavity. As Alpha puts it, if you can see it, you can weld it.

Better Molds Faster

For Phoenix Laser Solutions, this capability is a key competitive advantage for the business. Besides the precision of the process itself, pulsed laser welding lets them work with a wide variety of materials and weld dissimilar materials. For example, you may want to repair a worn mold feature with a harder material than the base metal to improve its wear resistance over the original. Combined, all the advantages of pulsed laser welding allow Phoenix to deliver repaired molds that perform as well as when they were brand new.

Now these tools can be repaired multiple times. That alone has huge financial implications for the processor that owns them.

A benefit for both the repair shop and its customers, pulsed laser welding is more precise so that the repair process is shortened, due to limiting the damage to surrounding areas of the weld. This precision decreases machining and rework time because there is less weld to remove.

Whether you repair molds as a service business, or have a tool shop that does it in-house, this is definitely a technology to investigate. It will make your business more competitive and save time and money in the long run.

Go to Alpha Laser for more information on pulsed laser welding equipment and to Phoenix Laser Solutions for more on laser welding repair services.