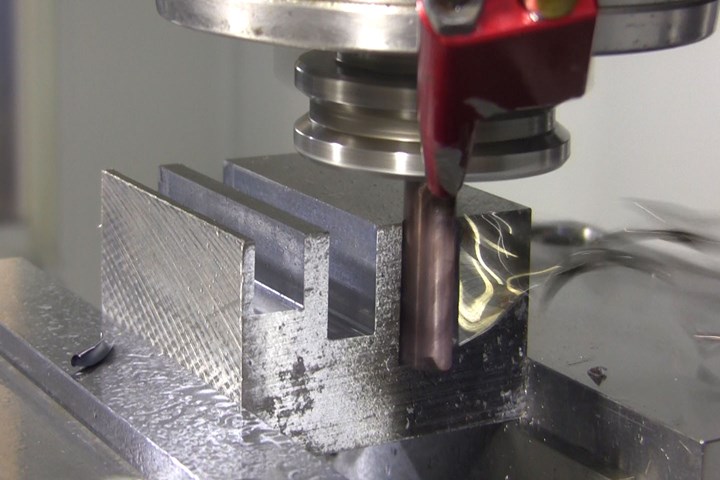

Roughing End Mill Line Combats High Metal Removal Operations

Kyocera SGS announces the expansion of the Z-Carb HPR five-flute end mill portfolio with more than 900 tools.

To meet customer demands, Kyocera SGS Precision Tools has expanded the Z-Carb HPR high-performance five-flute end mill line with more than 900 new tools featuring new long, extended reach and chip breaker options to combat a wider variety of high metal removal roughing operations and optimize surface finishes.

Utilized extensively in automotive, general machining, mold and die and other industries, Z-Carb HPR’s five-flute design is engineered to increase productivity by 20-40% over conventional three- and four-flute end mills. The line features variable indexing geometry, which improves chatter suppression over symmetrical designs, and is equipped with various lengths, reach, square and corner radius styles, along with new chip breaker options to address different machining situations.

Z-Carb HPR end mills are coated with Ti-Namite-M for high heat resistance and tool life enhancement, and Ti-Namite-A for wear, edge buildup resistance and extended tool life, ensuring high performance in difficult-to-machine materials like titanium, stainless steel, cast iron, high-temp alloys and more. Special tooling design attributes are available upon request.

The series’ cutting diameter is 1/8-1", and length of cut ¼-3". Special options include internal coolant, weldon flat and chip breaker.

Related Content

-

Treatment and Disposal of Used Metalworking Fluids

With greater emphasis on fluid longevity and fluid recycling, it is important to remember that water-based metalworking fluids are “consumable” and have a finite life.

-

Maintaining a Wire EDM Machine

To achieve the ultimate capability and level of productivity from your wire EDM on a consistent, repeatable and reliable basis, regular maintenance is a required task.

-

Laser Welding Versus Micro Welding

The latest battle in finely detailed restoration/repair of mold materials.

.png;maxWidth=300;quality=90)