New Temperature Controller, Hot Runner for Micro Molders

Günther unveiled a new hot runner temperature controller and a specialized hot runner built specifically for the Babyplast line of molding machines at K 2022.

Günther’s blueMaster pro hot runner temperature controller can be accessed via smart devices.

Photo Credit, all images: Plastics Technology

Günther Hot Runner Technology debuted the blueMaster pro hot runner temperature controller at K 2022, offering control of six to 24 control circuits and the ability to control them via web-enabled devices, including smart phones. In addition to the built-in display, the blueMaster pro enable users to access several devices on a tablet or quickly check the operating status remotely.

An assistance function provides support when setting up new tools and multi-cavity molds and multi-component systems can be operated using the integrated group management feature. To achieve such integrated temperature control data interface standardization was required, and the blueMaster pro meets Euromap 82.2 protocol.

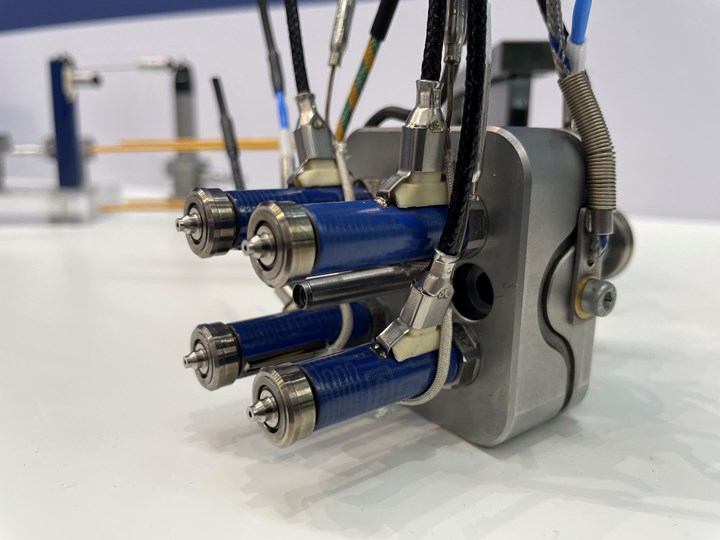

In addition, the company unveiled what it says is the first needle valve hot runner, the Babyplast line of molding machines. Mold height is typically a limiting issue, but Günther overcame this with a patented actuation system. Running at Babyplast’s K 2022 booth, the specialized hot runner molded a 0.35-g part from PA6. The mold is headed to a customer that will use it to run PEEK. The four-drop system features a pitch of 26 × 26 mm, with a needle diameter of 1 mm.

Targeting micro injection molding, including the Babyplast machine, this new hot runner has a 1-mm needle diameter.

Related Content

-

Hands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.

-

Revisiting Some Hot Runner Fundamentals

What exactly does a hot runner do? If you’ve been in the injection molding industry for any length of time, you might think the answer is obvious, but it is not.

-

How to Eliminate Chatter

Here are techniques commonly used to combat chatter and guidelines to establish a foundation for optimizing the moldmaking process.