Light-Blocking Co-Injected Barrier Extends Thin Wall Packaging, PET Preform Shelf Life

Mold-Master’s co-injection multi-layer systems are now available for injection light-blocking barrier materials to reduce light transmittance by up to 99.9%.

Photo Credit: Mold-Masters

Mold-Masters has recently made its co-injection multi-layer systems available for injecting light-blocking barrier materials as the core layer for thin wall packaging and PET bottle applications. Light-blocking barriers reportedly reduce light transmittance by up to 99.9% to extend product shelf life and preserve freshness and flavor of dairy products.

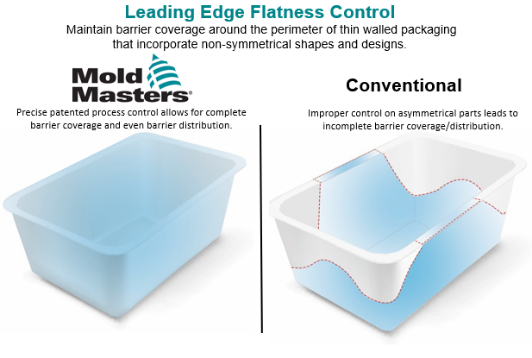

The proprietary nozzle designs allow two different resins to be combined into a single, three-layer melt stream. This enables users to inject the core layer in a single process without sacrificing part quality or cycle time. Depending on the part type and shape. Dosing of Black Core can be customized to meet the specific requirements of the molded part. Precise process control enhances molded part properties by adjusting barrier layer placement and thickness, and ensures uniform distribution. Mold-Masters says its patented process control capabilities also allows it to maintain complete core barrier coverage around the perimeter of non-symmetrical shapes and designs without core breakthrough. Mold-Masters currently offers light barrier co-injection hot halves in any cavitation and its system is compatible with virgin or recycled material. In many cases, the existing cold half can be reused. A co-injection hot half only replaces the mono-layer hot half.

Mold-Masters co-injection systems offer some additional benefits. For PET preforms, there is opportunity to take thickness out of the container and achieve the same light blocking performance with a thinner wall. This translates into a lower cost package through potential for overall material cost savings. About 80% of the package cost is the raw material. For thin wall packaging applications, Mold-Masters’ co-injection process offers optimized heat seal bond (uniform thickness for good adhesion), a fully encapsulated barrier, dimensional stability, additional design freedom and is compatible with IML (in-mold labeling).

Mold-Masters co-injection systems are fully customizable. They can also be used for injecting a moisture or gas barrier in a range of other container shapes, sizes and applications. Mold-Masters claims its co-injection systems have been successfully utilized to process a wide range of materials including bio-resins and post-consumer recycled (PCR) materials.

Related Content

-

Machining Center Spindles: What You Need to Know

Why and how to research spindle technology before purchasing a machining center.

-

It Starts With the Part: A Plastic Part Checklist Ensures Good Mold Design

All successful mold build projects start with examining the part to be molded to ensure it is moldable and will meet the customers' production objectives.

-

6 Ways to Optimize High-Feed Milling

High-feed milling can significantly outweigh potential reliability challenges. Consider these six strategies in order to make high-feed milling successful for your business.