Gantry Machines Meet Industry-Specific Requirements for Mold and Die Makers

Zimmerman is putting on a virtual display of its highly rigid and efficient FZ42, FZ37 and FZ32 machines at IMTS 2022.

Share

Read Next

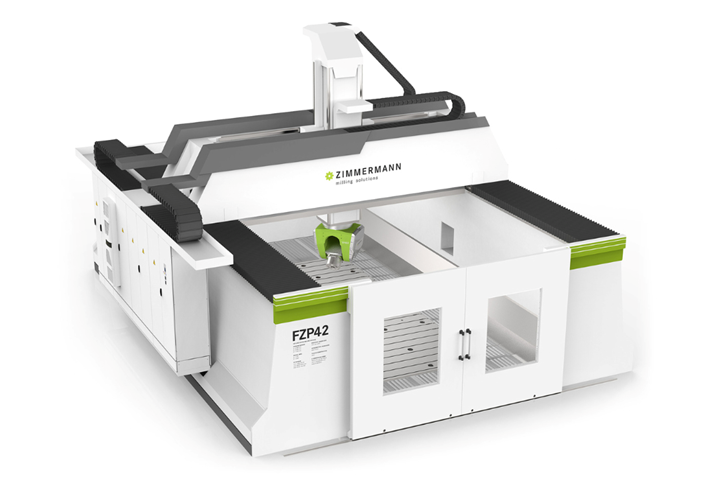

Zimmermann Milling Solutions, a global high-tech supplier of portal milling machines, is virtually showing three new gantry machines at its IMTS booth, including the FZ42, FZ37 and FZ32, all of which are well suited to mold and die making.

Zimmerman says its biggest, double-bridged gantry sets new standards for dynamic roughing while maintaining high precision. The FZ42 CNC gantry milling machine combining work areas of different sizes, travels, milling heads and CNC controls. Regardless of weight and size, the milling process is said to be exact. Furthermore, the gantry design is particularly suitable for the entire range of component machining, according to the company. The structurally rigid center-guiding gantry, cross and Z-Ram and dynamic milling head enable a consistent, efficient milling process. This combination of high thermal stability and rigidity meets industry-specific requirements in tool and die making, aerospace and automotive industries.

Just as strength and agility make an athlete perform at his/her best, the same is said to be true for the newest high-performance gantry FZ37. Due to its modular system concept, Zimmerman says the FZ37 is available in various sizes, custom configuration and CNC controls. The newly designed gantry with center-guided Z-Ram in combination with Zimmermann’s dynamic milling heads ensure an efficient and consistent milling process. The high thermal stability and rigidity meet industry-specific requirements in model, tool and die making as well as in the aerospace and automotive industries.

The FZ32 is a high-performance “athlete” for dynamic machining of aluminum, fiber-reinforced composites, plastics and tooling board. Its thermosymmetrical design results in high surface quality and accuracy. The rigid center-guiding gantry enables the company to meet the increasing demands in model and moldmaking as well as aerospace. Additionally, the flexible design of the FZP machine line offers various sizes and configurations through its modular system as well as extensive equipment options and a fully enclosed work area, including effective dust extraction systems and more.

Related Content

-

The Benefits of Hand Scraping

Accuracy and flatness are two benefits of hand scraping that help improve machine loop stiffness, workpiece surface finish and component geometry.

-

Predictive Manufacturing Moves Mold Builder into Advanced Medical Component Manufacturing

From a hot rod hobby, medical molds and shop performance to technology extremes, key relationships and a growth strategy, it’s obvious details matter at Eden Tool.

-

Leading Mold Manufacturers Share Best Practices for Improving Efficiency

Precise Tooling Solutions, X-Cell Tool and Mold, M&M Tool and Mold, Ameritech Die & Mold, and Cavalier Tool & Manufacturing, sit down for a fast-paced Q&A focused on strategies for improving efficiencies across their operations.