CAM Software Release Features Increase Throughput

BobCAD-CAM highlights its CAM software, which offers moldmakers new and improved features such as CAM tree templates and a range of toolpath technologies.

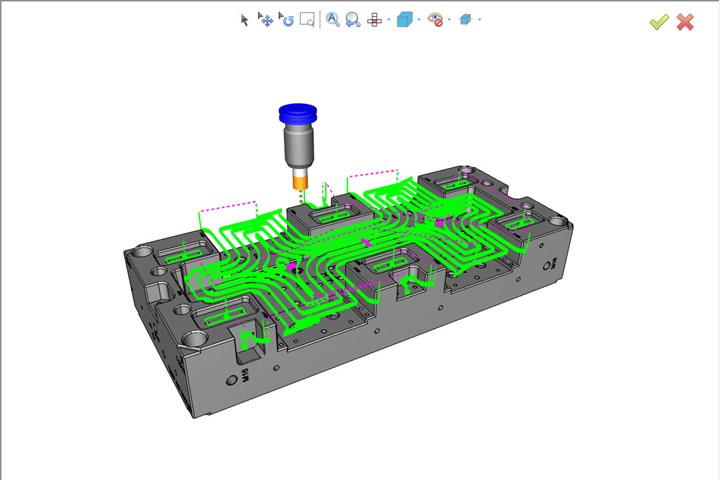

Advanced Roughing with toolpath smoothing. Photo Credit: BobCAD-CAM

New CAM software released by BobCAD-CAM Inc. is said to help moldmakers increase throughput. The company points to SSI Mexico as an example, which develops toolpaths, runs simulations, generates setup sheets and posts g-code programs for all the CNC machines in its mold shop using BobCAD-CAM’s software solution, saving programming time and enabling faster mold production.

For example, the software offers CAM tree templates. The new feature enables shops to capture an entire machining process to reuse on future jobs. Everything from the tools used in the job, stock size/location, fixture definition, origin and machining features are saved in the template, ultimately reducing programming steps.

Toolpath Smoothing is able to quickly removes stock while ensuring smooth tool motion via the advanced roughing offset pattern and smoothing options. Fine adjustment found in the smoothing options reportedly results in more consistent cutting and better results on corners and link moves, among other control settings.

The Advanced Feedrate Control feature offers automatic ramp up and down feeds based on material conditions, and the Flatlands toolpath operation automatically targets flat/horizontal part features. Independent control of stock for finish in X, Y and Z is possible and automatic detection eliminates the need to individually select part features.

BobCAD-CAM notes that its software product development is ongoing, and that new toolpath technology will be implemented, including Barrel Mills, three-, four- and five-axis deburring, three- to five-axis conversion and more.

Related Content

-

MoldMaking Technology's Most-Viewed Content 2022: Products

MMT shares the five top-viewed technologies, equipment and services of 2022 in each Engineer, Build, Maintain and Manage tenet based on Google Analytics.

-

What is Scientific Maintenance? Part 2

Part two of this three-part series explains specific data that toolrooms must collect, analyze and use to truly advance to a scientific maintenance culture where you can measure real data and drive decisions.

-

Leading Mold Manufacturers Share Best Practices for Improving Efficiency

Precise Tooling Solutions, X-Cell Tool and Mold, M&M Tool and Mold, Ameritech Die & Mold, and Cavalier Tool & Manufacturing, sit down for a fast-paced Q&A focused on strategies for improving efficiencies across their operations.

_970x90 1.png;maxWidth=970;quality=90)

.png;maxWidth=300;quality=90)