Graphite vs. Copper Electrode Material for EDM Applications, Part 1

If you’ve been torn in the long-standing, unresolved debate over whether graphite or copper is a better EDM electrode material, here are some considerations identifying differences in cost, detail and performance to help you select the appropriate material for EDM applications.

This is part one of a two part series

There has been a long-standing, unresolved debate over whether graphite or copper is a better EDM electrode material. The preference is most always the same in any one geographical region. In North America, the preferred electrode material has shifted from copper to graphite. In Europe and Asia, many argue that copper is the preferable material.

Without question, graphite is the predominantly used electrode material in the United States, where at least 95 percent of electrodes are produced from this material. Steady increases in graphite use in Europe over the past decade have resulted in an electrode material ratio of 75 percent graphite to 25 percent copper. Asia follows with estimations of 45 percent graphite versus 55 percent copper. Perhaps it’s time to take a closer look at both materials to identify the differences and help you select the one that is most appropriate for your EDM applications.

Electrode Material Considerations

Material Variety

Graphite is produced with a wide range of material characteristics, enabling you to match the electrode material properties to the EDM application. Less-critical applications with electrode features such as a large radius, an open tolerance or minimal EDM requirements would use an economically-priced graphite material with large particles and lower strengths. However, a highly detailed electrode with critical features, extreme tolerances and stringent EDM requirements would entail a more premium graphite to fit the needs of this application.

On the other hand, due to the high purity value required for efficient EDMing, the types of copper available on the market and used in EDM applications are limited. This minimizes the ability to match material characteristics to the EDM application. The most commonly used types are electrolytic copper and tellurium copper, which vary slightly in elemental composition and are both cast as a solid.

Cost

Copper is often considered a commodity material and can be less costly than graphite in the bulk or blank stage. Many graphite materials are considered specialty materials and, as such, can be more costly. In addition, copper is recyclable whereas graphite is limited in its ability to be reclaimed. However, with the wide range of graphite materials available on the market today, it is possible to find some low-quality EDM grades that are more economical than copper. To establish the true cost of copper versus graphite, the value of machining the electrode must also be considered. Even with the more expensive graphite materials, the machining costs often offset any savings that are realized with the copper.

For example, a quote was recently solicited for a simple electrode blank with a ground finish on the top and bottom. The quote was received with copper at $4.68 per cubic inch, while a premium grade of graphite was quoted at $6.80 per cubic inch, or 45 percent more costly. However, when the cost of machining a simple, finished electrode was included, the story changed. In this case, the finished graphite electrode was quoted at $15.50 each, whereas the copper electrode (“oxygen free”) was quoted as $95 each. Due to the soft, ductile characteristic of copper, it is often gummy, and conventional machining practices (such as feeds and speeds) must be altered to accommodate. This can be mitigated with tellurium copper, but EDM performance may be jeopardized. On the other hand, graphite is not gummy and can be conventionally machined very easily. However, machining graphite generates significant dust, which must be collected through an effective vacuum system with HEPA-type filtration.

Detail

In EDM applications, the electrical current tends to concentrate at sharp edges and corners. Copper’s low melting point does not allow it to handle current density as effectively as graphite, so features on a single copper electrode must be similar in detail. It is not wise to EDM with varying details on the same copper electrode. This is because the higher current required to efficiently EDM larger electrode details exceeds the current allowable for the smaller detail.

With copper electrodes, high current density on smaller, more intricate detail increases the electrode wear. Also, when machining intricate detail or EDMing at high current densities, a copper electrode may move or flex as material stress is relieved. This limits the ability to maintain the very tight tolerances required on many of today’s molds. Graphite performs very well at a high current density even with complex geometry. Graphite electrodes allow for efficient EDMing, even with varying details on the same electrode. Therefore, the number of graphite electrodes required to perform a job can be significantly reduced.

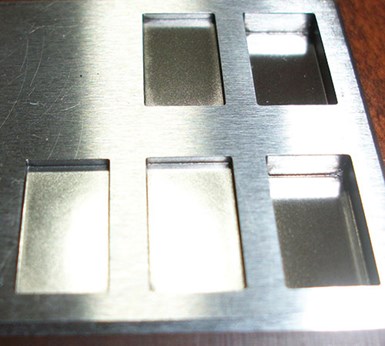

Figure 1 shows the results achieved by one shop that combined several electrode details into one graphite electrode instead of multiple copper electrodes. This particular mold required more than 100 copper electrodes to complete the job, while fewer than 30 graphite electrodes were required. In addition, with metallic electrodes, the machining process creates rough edges or “burrs” that must be removed. This deburring process is typically done by hand. With graphite, no burr is created in the machining process and as such, the deburring step is eliminated.

Figure 1 shows the results achieved by one shop that combined several electrode details into one graphite electrode instead of multiple copper electrodes. This particular mold required more than 100 copper electrodes to complete the job, while fewer than 30 graphite electrodes were required. In addition, with metallic electrodes, the machining process creates rough edges or “burrs” that must be removed. This deburring process is typically done by hand. With graphite, no burr is created in the machining process and as such, the deburring step is eliminated.EDM Performance

Metal Removal Rates

An electrode material’s thermophysical properties determine its ability to process the energy of the EDM cut and remove metal. In generating a spark, peak current is discharged only after the gap between the electrode and workpiece has been ionized. At this point, the electrode emits electrons that collide with the molecules of the dielectric fluid. As a result, the fluid is vaporized and an energy channel is formed that allows the spark to take place. For this to happen, the electrode material must be hot enough for electrons to absorb enough energy to escape and work to create the energy channel.

For copper electrodes to release electrons in the gap, the temperature must be high enough for these electrons to absorb sufficient energy.1 As a result, these high temperatures tend to burn some of the copper electrode away. In order to generate this heat, the on times for copper electrodes are generally much higher than for graphite electrodes. However, due to its carbon base, a graphite electrode is able to emit these electrons at much lower temperatures and does not require the extended on times for electrons to release and create the energy channel. Therefore, the time required to form the energy channel is considerably less. Since the graphite initializes the spark faster, significantly higher metal removal rates are the result.

Wear

Electrode wear is a constant concern because excessive wear results in adding electrodes or redressing electrodes more often. Graphite is able to achieve electrode wear of less than 1 percent in relation to the depth of cut at machine parameters much more aggressive than copper electrodes. This is achieved through a “replating” process during which molten particles from the workpiece may penetrate into the structure of the graphite electrode and reduce the amount of wear caused by the EDM process. The melting temperature of most standard work metals being EDMed is around 1,500°C. This exceeds that of copper, which is around 1,100°C. Any molten particles being ejected out of the EDM cut are likely to carry a thermoelectric charge and have temperatures that do not permit them to affix to the copper electrode. In this case, the molten particles may actually create secondary discharging and erode the copper electrode away.

This means that the high amperage and long on times of a roughing condition (and the process of replating) actually preserve the graphite electrode but is detrimental to the copper electrode which erodes away at these settings. On the contrary, in the finishing stages, with low amperage and short on-times, the graphite electrode has a tendency to wear at a faster rate than copper. However, since electrode wear is a ratio of the amount of material removed in the EDM cut, the actual wear on either a graphite or copper electrode is minimal in the finishing stage and sometimes immeasurable.

Surface Finish

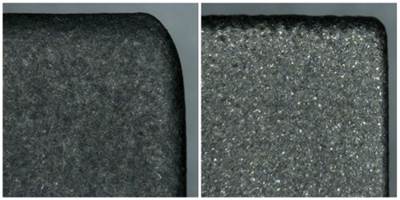

Because it is cast as a solid with no porosity, it goes without saying that copper electrodes provide very fine surface finishes. However, with the sophistication of today’s EDM sinker technology, the surface finish gap between graphite and copper has narrowed significantly. Fine-grain graphite electrodes are now able to deliver surface finishes similar to copper with comparable electrode wear. With the proper electrode material selection and machine parameters, graphite is able to achieve near mirror finishes without the use of a powder additive and mirror-like finishes with the additive.

Figure 2 - A fine surface finish can be achieved with an appropriate graphite electrode material and proper machine parameters.

Figure 2 shows EDM test cuts measuring 0.260 by 0.510 inch. The two pockets on the right were machined to a depth of 0.100 inch with an 8 VDI finish using graphite and standard EDM technology without a powder additive. This is a very good finish for a fine-grain graphite. While copper can achieve finer surface finishes (down to 0 VDI), they are not often required in EDM. Finer surface finishes are generally achieved by a post-EDM polishing process, regardless of the electrode type used.

Summary

Conducting test burns and tracking results will help determine the monetary impact that the electrode material has on an EDM application. Part 2 of this article will review the results of EDM testing conducted with both graphite and copper, and reveal the bottom-line cost for each. With all of this information, you will then be able make an informed decision on the electrode material type best suited for a specific EDM application.

Related Content

Maintaining a Wire EDM Machine

To achieve the ultimate capability and level of productivity from your wire EDM on a consistent, repeatable and reliable basis, regular maintenance is a required task.

Read MoreHow to Analyze and Optimize Cutting Conditions to Reduce Cycle Time

Plastic injection mold design and manufacturing company puts NC program optimization software module to the test. The results were surprising.

Read MoreRevisiting Some Hot Runner Fundamentals

What exactly does a hot runner do? If you’ve been in the injection molding industry for any length of time, you might think the answer is obvious, but it is not.

Read MoreHands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.

Read MoreRead Next

Advantages and Disadvantages of Copper and Graphite Electrodes

Both copper and graphite provide approximately the same end result, so it is important for a shop to consider the advantages and disadvantages of each material in order to discover what would work best in their shop floor environment.

Read MoreGraphite vs. Copper Electrode Material for EDM Applications, Part 2

Test findings and a cost of ownership model help identify the monetary impact graphite and copper electrode materials have on manufacturing.

Read More