Improved Graphite Electrode Machining

When a more productive and cost-effective method of machining graphite electrodes was needed, this moldmaker turned to a solid carbide modular milling system.

In the moldmaking business, survival requires precision and teamwork. Those are two lessons that German moldmaker Spindler Formenbau GmbH has learned well during its 38 years in business.

Spindler builds a range of multi-component and stack molds for both thermoplastic and thermoset processing for the automotive, electronics, medical and office furniture industries, among others. Its molds are used to produce components such as optical lenses, petri dishes, furniture components, and telephone and switch housings, to name a few.

As part of its approach to business, Spindler partners closely with its customers and with a select group of suppliers such as Walter. When looking for a solution to improve its graphite machining, Spindler found both a productivity boost and increased tool life with Walter’s Prototyp ConeFit solid carbide modular milling system.

Partnering to Meet Customer Demands

Spindler has a digital arsenal of CAD/CAM software and surface digitizing machines for product and mold design, and also deploys five-axis milling, HSC milling and wire EDM processes to ensure the molds it manufactures meet customer requirements, which vary from special steel molds with long tool life, to high-gloss-polished or etched molds that produce visually sophisticated molded components. It can accommodate molds as large as 1,200 by 900 mm (47 by 35 inches) with maximum weight of 4.5 tons. Spindler also has its own injection molding machines that can handle molds as large as 500 by 500 mm (20 by 20 inches).

Even with the company’s in-house capabilities, however, Spindler knows that successful manufacturing requires a cooperative approach with not only its customers, but also its technology suppliers. That’s one reason Spindler has worked closely for years with cutting tool supplier Walter, resulting in the introduction and optimization of new cutting technologies.

When Spindler decided to change from copper to graphite electrodes, which requires different tools with long tool life, its initial solution was Walter’s standard PCD-coated solid carbide cutters. These cutters offered the quality Spindler had grown to expect, but there was a catch. Because of the high volumes Spindler was producing, these tools were too expensive with regard to tool life. The company needed an alternative that would significantly reduce its tool costs for finishing and roughing.

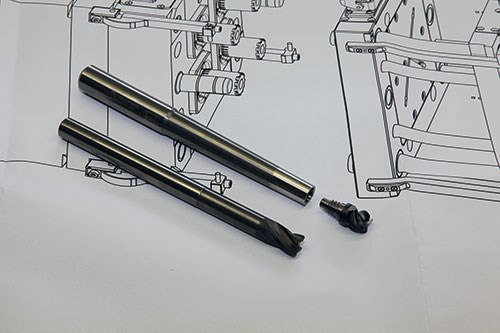

Walter responded with its Prototyp ConeFit, a modular solid carbide milling system with a self-centering thread designed to promote axial and radial alignment, deliver high rigidity, and offer superior stability due to its short taper and support face. The system is also highly flexible, with a broad spectrum of geometries and shank variants that can be quickly changed to fit a variety of spindles.

“With this modular milling system and the carbide shank, Spindler has an excellent tool for HSC machining,” says Leonhard Boschert of Walter AG Technical Advice and Sales. “The customer simply screws the cutting heads required for the respective task into the shank.”

Extreme Effects

Spindler uses various corner-radii and ballnose end mills from the Prototyp ConeFit series. As a result, the company says tool life has increased by four times during graphite electrode machining when compared to tool life with the standard tool. According to Anian Manuel Spindler, managing director for Spindler, the ConeFit’s modified geometry and diamond layer ensure significantly increased wear resistance during graphite milling.

Spindler also often needs special shanks, such as for machining deep components. “With the ConeFit system, we can simply attach the milling heads required in each case,” Mr. Spindler notes. ConeFit’s modular interchangeable head system offers a large number of steel, carbide and monoblock toolholders that enable various PCD-coated heads to be quickly and easily attached to the different adaptors.

For roughing and finishing, Spindler's PCD-coated solid carbide end mills also were replaced with new ConeFit Graphit PCD-coated end mills, which Mr. Spindler says resulted in an improved cost-benefit ratio, as well as a significantly more stable process with higher operational smoothness. “The system and its modified geometry has lowered our tool costs to one-third of previous costs,” he says.

Summary

According to Spindler, the ConeFit product range, with its diamond coating specially designed for roughing and finishing graphite electrodes for molds and dies; its modified macro- and micro-geometry; and its modular, interchangeable head system, proved to be the solution the company was looking for to improve its electrode machining processes with extended tool life.

Read Next

How to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreYour Guide to Smarter, Faster Mold Design

Dive into expert-curated content delivering proven solutions for mold optimization, manufacturability and precision performance.

Read More