Machining

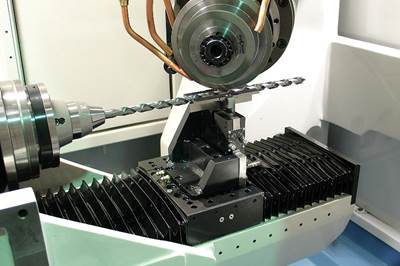

How to Overcome Common Deep-Hole Drilling Challenges

Producing deep holes effectively and efficiently is a challenging application that requires cutting tool solutions that offer predictable cutter life, accurate surface finish and repeatability.

Read MoreDouble-Column Machining Centers Improve Accuracy, Speed of Mold Machining

IMTS 2024: Takumi highlights its UA400 five-axis and VC1200 three-axis machining centers for mold machining, designed to minimize thermal growth and accelerate feed rates.

Read MoreQuick Mold Change and LSR Tooling Trends

In this short but informational MMT Chat, MMT Editorial Director, Christina Fuges, sits down with Roembke Mfg. & Design Inc.’s Business Development Manager, Adam Shaal, to talk about a quick mold change solution, LSR tooling and the future moldmaker.

WatchThree-Axis Mill Delivers High Performance for Mold and Die Work

IMTS 2024: The VMX42Di machine, among other featured models, demonstrates Hurco’s Companies’ focus on productive manufacturing and automation/CNC machine tending.

Read MoreVMC Helps Avoid Imperfections in Molds During Processing

IMTS2024: Hwacheon Machinery America Inc. highlights its Sirius-Um+ machinery, designed for the hard milling of complex applications including those for mold and die.

Read MoreHMC Targets Less Setup Time, Energy Consumption

INH 63 by DMG MORI integrates a variety of machining processes to ensure moldmakers are more productive, while meeting energy-efficiency goals.

Read MoreTechnology Review and Sourcing Guide 2024: Machining

Understanding both traditional and advanced machining techniques is vital to overcoming various dimensional and finish challenges associated with mold machining. Access more information about machining in this exclusive, online-only content, including a suppliers list, machining products and more.

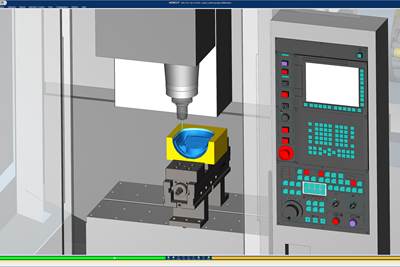

Read MoreCNC Platform Creates Adaptable Interface for Workholding

IMTS 2024: Features such as advanced collision protection and greater operational functionality make Heidenhain’s TNC7 CNC control platform critical for mold builders, who often face multi-surface machining.

WatchHow to Analyze and Optimize Cutting Conditions to Reduce Cycle Time

Plastic injection mold design and manufacturing company puts NC program optimization software module to the test. The results were surprising.

Read MoreCustom Machining Solutions Feature Automation, Digitalization

IMTS 2024: Mazak features advanced machining solutions designed to boost productivity in automation, multitasking capabilities and machine tool technology.

Read More

-02.jpg;maxWidth=300;quality=90)