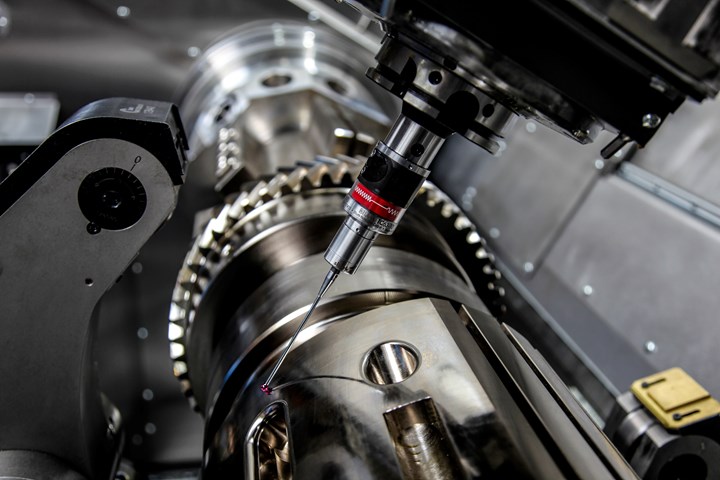

Touch Probe Delivers Fast, Precise and Reliable Mold Inspection

High scanning and probing speeds and a high-precision measuring mechanism characterize Blum-Novotest’s Digilog test probe systems.

Blum-Novotest, a manufacturer of innovative, high-quality measuring and testing technologies, features its Digilog test probe systems that enable high scanning and probing speeds in the hard-use, high-output molding environments. Complex contours can be monitored in series at up to 2 m/min to increase productivity while maintaining strict specifications.

Digilog TC63/64/76 probes provide high-precision digital measurements and lightning-fast analogue scans, according to the company. They feature BRC radio technology and are particularly suited for mold inspection. By analogue scanning the workpiece surface, machining errors are quickly and reliably detected. Shark360 technology, a high-precision, face-geared measuring mechanism, delivers defined deflection direction and constant deflection forces for maximum accuracy. The TC63 Digilog probe is the modular version that enables extensions and elbows attachments. The TC76 Digilog is a hard-wired alternative.

Related Content

-

How to Overcome Complex Mold Texturing Problems

Key benefits when considering laser technology for mold texturing and repair.

-

Hands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.

-

5 Hot Runner Tips for Moldmakers and Molders

Best practices for initial hot runner tryouts and effective preventive maintenance.