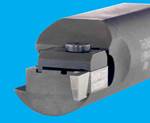

Angled Round Toolholders Increase Position Versatility

Made for use in Thinbit inserts, the angled round toolholders are designed for CNC, conventional and end working positions on Swiss screw machines.

Photo Credit: Thinbit

Thinbit, manufactured by Kaiser Tool Company Inc., introduces its angled round toolholders, which are designed for CNC, conventional and end working positions on Swiss screw machines.

The angled round toolholders position the insert at 30°, 45° or 60° angles for reliefs, undercuts and angled OD and face grooves. Round shank sizes are available in diameters of ½, 5/8, ¾, and 1 in. and 20 mm and 25 mm.

Made for use with Thinbit inserts in grades for ferrous and non-ferrous materials. Inserts are available in sizes 0.004-0.150 in. in 0.001-in. increments coated with TiN, TiAlN, TiCN, diamond film or uncoated.

Related Content

-

Hands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.

-

How to Analyze and Optimize Cutting Conditions to Reduce Cycle Time

Plastic injection mold design and manufacturing company puts NC program optimization software module to the test. The results were surprising.

-

Machining Center Spindles: What You Need to Know

Why and how to research spindle technology before purchasing a machining center.

(4).png;maxWidth=300;quality=90)