Mold & Die Workshop Co-Hosted by Three Leading Companies

The Mold & Die workshop – hosted by Emuge-Franken USA, GROB Systems Inc. and Open Mind Technologies – will be held on July 20, 2022 at the Emuge Technology Center in West Boylston, Massachusetts.

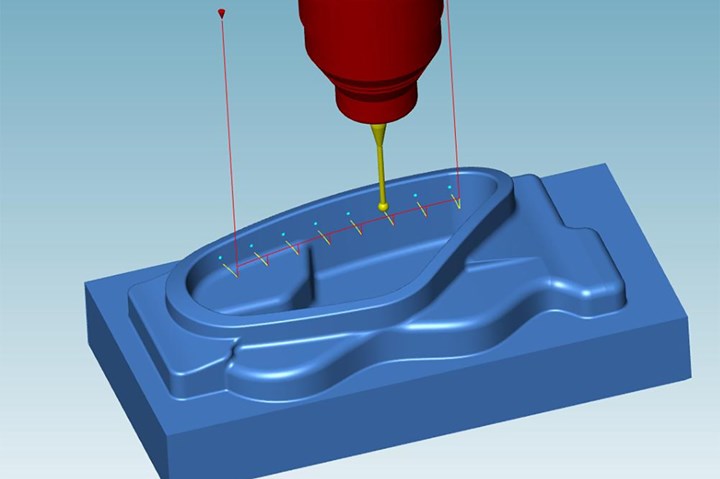

Emuge-Franken USA, GROB Systems Inc. and Open Mind Technologies announced the companies are jointly holding a Mold & Die Workshop on July 20, 2022 from 10:00 a.m. to 1:00 p.m. ET at the Emuge Technology Center in West Boylston, Massachusetts. The workshop will cover live machining demonstrations on how to optimize mold and die accuracy by combining advanced tooling, machining and CAM technologies. Attendees will learn how Open Mind’s hyperMILL CAM software machining strategies will maximize programming for Emuge-Franken tooling on a GROB G550a five-axis CNC machining center. Manufacturing professionals can register to attend here.

Key workshop topics and demonstrations will include achieving high quality surface finishes with hyperMILL’s high precision surface mode by machining directly to the surface instead of an “approximated mesh,” and applying the CAM software’s smooth overlap capability which reportedly minimizes witness marks at the blending of adjoining part features.

Additionally, demonstrations will show how to utilize the GROB G550a five-axis capabilities to properly orient and consistently maintain the Emuge-Franken Multi-Cut Duplex End Mill in the cut, while extending tool life; how to maximize the efficiency of the machining process with hyperMILL’s auto-indexing function to automatically generate multiple 3+2 segments as an alternative to five-axis; how to use shorter, smaller diameter tools for more aggressive machining by combining GROB’s rigid cross-slide design and long Z-axis stroke with hyperMILL’s five-axis rest machining strategy and EMUGE’s rigid FPC toolholder; and how to optimize the workflow within multiple application stages by using process probing strategies.

Manufacturing professionals can register to attend here.

Related Content

-

Making Mentoring Work | MMT Chat Part 2

Three of the TK Mold and Engineering team in Romeo, Michigan join me for Part 2 of this MMT Chat on mentorship by sharing how the AMBA’s Meet a Mentor Program works, lessons learned (and applied) and the way your shop can join this effort.

-

Unique Mold Design Apprenticeship Using Untapped Resources

To help fill his mold design skills gap, Jeff Mertz of Anova Innovations, is focused on high schools and underprivileged school districts, a school that has lower graduation and college entrance rates. The goal is a student-run enterprise.

-

How to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.