Untapped Production

Automation allows this mold manufacturer to run its EDM machines nonstop for months.

In today’s competitive manufacturing environment, every operation has to find ways to maximize production in order to be successful. This is especially true in the case of a company that is hoping to grow its business.

Custom Mold & Design (CMD), a manufacturer of complex, multi-cavity, high-precision molds, found its solution in advanced modular automation, which it has used to capture huge blocks of extra production time that previously went untapped and significantly increase machine utilization rates. Automation has enabled the company to reduce necessary human intervention and decrease overtime costs associated with running non-automated machines at night and over the weekends. In the past, during weekend hours, operators would come into the shop intermittently to keep jobs running. Today, at least three of the shop’s sinker EDM machines can run unmanned during that time. Plus, with the machines also operating unattended during the week, the shop’s highly skilled machinists are free to attend to more hands-on operations on other machines with shorter burn times.

Adding Automation

Increased business and the acquisition of advanced manufacturing technology drove the need for automation at CMD, which was founded more than 50 years ago in New Hope, Minnesota, by Duane Treiber and is now owned by Ray Newkirk. In 2014 CMD moved to Forest Lake, Minnesota.

When the shop needed to expand capacity and boost equipment output in 2011, it acquired an additional sinker EDM machine. In the same year, CMD formed its first automated cell when it teamed the two machines with a new Compact standalone robot from Arlington Heights, Illinois-based Erowa Technology Inc. This system worked so well that earlier this year the shop purchased another sinker EDM machine and a second Erowa robotic system with the intention of eventually adding a second EDM machine to this new cell.

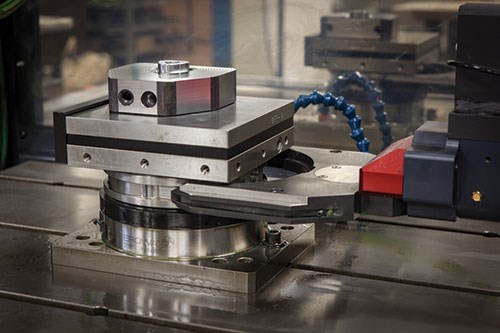

Erowa Compact robots are pick-and-place systems that serve one or two machines for milling and/or EDM applications. According to CMD, they integrate seamlessly into the controls of its sinker EDM machines and provide storage for as many as 108 electrodes and 20 workpiece pallet stations. The robot’s arm travels 47.244 inches in the X axis and accommodates maximum weights (workpiece and pallet) of more than 66 pounds and workpieces as large as 8 × 8 inches.

Another key aspect of each of the automated cells is an Erowa modular integrated workholding system. With it, raw pieces of electrode graphite are clamped to a holder and then seamlessly transfer on that same holder from a graphite machining center to the Erowa robot storage unit and then into the EDM machine. Operators never have to unclamp, re-clamp or relocate parts to determine zero positions as parts move from one machine to the next.

“The transition into automation was seamless with Erowa,” says Bill Ellis, EDM manager at Custom Mold & Design. “A few of our people had previous automation experience, so once Erowa had the robots up and running, the learning curve was short. We were completely up to speed in a couple days.”

Making a Match

CMD builds molds, mostly from tool steels, with 16 and 32 cavities, as well as single-, two-, four- and eight-cavity molds, and high-precision tooling makes for easy and precise interchangeability. Tolerances run as tight as 0.0002 inch, and the shop does a lot of hard milling and five-axis machining in addition to EDM. To determine whether a job will run through an automated cell, CMD evaluates the complexity of the mold components as well as the number of electrodes required.

“A job requiring 50 or 60 electrodes to burn just one cavity, for instance, is obviously a perfect candidate, because the machine’s toolchanger lacks that much capacity,” Ellis explains. “Without the robots, operators would have to load the machine three different times with three different sets of electrodes. That is not running unattended, and if the machine was operating at night and needed more electrodes, it would have to sit until morning for someone to load it.”

Some jobs can require as many as 20 sets of electrodes, each running for 5 hours for a total processing time of 100 hours. Other jobs might require just one set of electrodes, but it might burn for 8 hours.

Ellis points out that almost any job is a candidate for the automated cells, but since CMD only has two such cells, the shop picks the jobs that match up best with automation. The decision, he adds, often boils down to the jobs that will be most cost-effective if run through the cells.

Growing and Evolving

“Automation technology is mandatory in today’s mold-building world,” says Bruce Cerepak, general manager at Custom Mold & Design. “Automation allows shops to extract every hour of production possible from today’s advanced, and oftentimes costly, machining technologies. While automation boosts the output of our existing workforce, it also motivates employees to work with and master higher levels of technology, attracting new customers with those higher levels of technological capabilities.”

At the time Newkirk purchased CMD in 2003, there were only 18 employees. Today, there are more than 75 people employed by the company, which continues to grow and evolve in both revenue and advanced manufacturing technology. According to Cerepak, CMD’s increased capacity puts it in position to take advantage of a shift toward more mold work being sourced to the United States.

“For us to expand our customer base, we will definitely need to add more advanced automation to other processes,” he adds. “Our current and future planned automation will further boost our equipment utilization and consistently improve overall business.”

Related Content

How to Eliminate Chatter

Here are techniques commonly used to combat chatter and guidelines to establish a foundation for optimizing the moldmaking process.

Read MoreHow to Analyze and Optimize Cutting Conditions to Reduce Cycle Time

Plastic injection mold design and manufacturing company puts NC program optimization software module to the test. The results were surprising.

Read More6 Ways to Optimize High-Feed Milling

High-feed milling can significantly outweigh potential reliability challenges. Consider these six strategies in order to make high-feed milling successful for your business.

Read MoreWhat You Need to Know About Hot Runner Systems and How to Optimize Their Performance

How to make the most out of the hot runner design, function and performance.

Read MoreRead Next

2014 Leadtime Leader Awards Winner: Westminster Tool Inc.—Bridging the Gap without Losing Focus

A strong sense of self and a focus on people enabled this mold manufacturer to rapidly expand pre- and post-manufacturing services without getting overwhelmed by its own growth.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreYour Guide to Smarter, Faster Mold Design

Dive into expert-curated content delivering proven solutions for mold optimization, manufacturability and precision performance.

Read More