Optimizing Common Roughing Technology

Keeping on top of the ever-advancing range of cutting technologies, edge geometry designs, materials and coatings is essential for achieving higher productivity, faster metal removal rates and more cost-effective machining processes.

Mold machining is performed with a wide range of cutting tools that are selected and optimized based on a variety of factors, including the process chain, process step specifications, final required geometry, surface integrity, workpiece material, machine tool specifications and environmental conditions. Keeping on top of the ever-advancing range of cutting technologies, edge geometry designs, materials and coatings, and then making smart investments in the right technology is essential for achieving higher productivity, faster metal removal rates and more cost-effective machining processes.

However, in many cases, shop management may argue that there is no pressure to change tooling and technology since moldmaking is not a mass production application, and many mold producers tend to remain loyal to their tried and true instruments.

For example, most mold builders will still use standard, round-shaped milling inserts for their rough milling applications, standard ISO turn inserts for rough turning on a lathe, and a high speed steel (HSS) drill or tap. In cases where there are specific holes to drill, or only one or two threads to tap, they cannot justify the cost of changing to newer tools, and the time savings is small. However, the reality is that there is a huge advantage for shops that adopt new cutting tool, machine tool and toolpath technology.

When rough milling a mold core or cavity, either an end mill (shank adaptation) or a shell mill (screw plus two keyways) with round inserts is the standard rule. And rightly so, as the cost is relatively low and this type of tooling excels in many milling applications, such as face, shoulder, and linear and circular ramp milling. However, when you try to efficiently optimize common roughing technology by examining each parameter of the milling process, you will discover that new cutting technologies and methods exist that can dramatically change the manufacturing process.

A round-shaped insert creates different approach angles when it meets the metal at each depth of cut. This means you must change the machining parameters for each depth. Moldmakers commonly apply consistent machining parameters for all mold parts using the same tool. Although this may be easy and safe for the shop employees, it limits productivity and efficient machining.

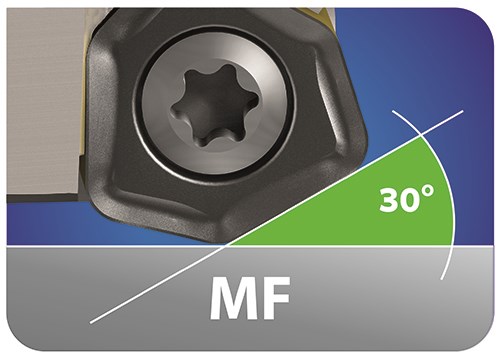

Today, milling tools exist that can enable mold shops to decrease machining time for each part. The approach angle for these tools is a linear constant 17 degrees (top figure) or 30 degrees (bottom figure) for fast-feed (FF) or medium-feed (MF) implementation. The same machining parameters can be used for each depth of cut applied. In addition, the tools provide very high metal removal rates and machining efficiency.

Having an open mind and adopting new technologies such as these can help bring productivity and performance innovation into the traditional mindset of many mold builders.

Related Content

-

6 Ways to Optimize High-Feed Milling

High-feed milling can significantly outweigh potential reliability challenges. Consider these six strategies in order to make high-feed milling successful for your business.

-

It Starts With the Part: A Plastic Part Checklist Ensures Good Mold Design

All successful mold build projects start with examining the part to be molded to ensure it is moldable and will meet the customers' production objectives.

-

How to Analyze and Optimize Cutting Conditions to Reduce Cycle Time

Plastic injection mold design and manufacturing company puts NC program optimization software module to the test. The results were surprising.