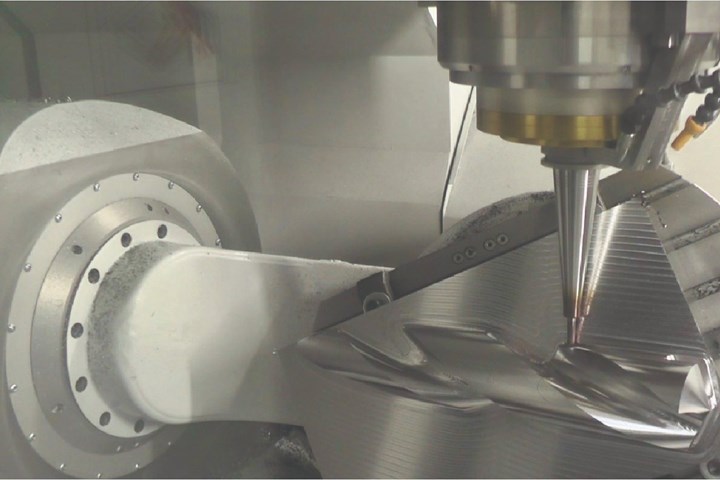

The increased complexity of plastic part geometries requires smaller cutting tools that run at significantly higher speeds, which are only 0.125-inch in diameter, generally. Image courtesy of Precise Tooling Solutions.

Five-axis machining is critical at Precise Tooling; talk about the importance of the cutting tools to that process for the molds you machine when it comes to your quality and consistency?

Don Dumoulin, president/owner: For quality and consistency, the tools must be selected correctly. We strive to keep up with the latest tool technology and use only high-performance tools with a demonstrated track record. We also recognize that today’s complex mold designs require that we purchase different tools with optimal geometry for unique customer applications.

Precise Tooling’s Phase 2 (2015-2017) was all about upgrading equipment. You doubled down and invested in the latest and greatest technology. Talk about how cutting tool technology was part of that.

Dumoulin: You are referring to the five-axis Roeders and Fermat machines we installed at our shop. These and other five-axis milling machines run at significantly higher speeds than previous generation machines.

The increased complexity of plastic part geometries requires smaller cutting tools that run at significantly higher speeds. On average, these newer cutting tools are only 0.125-inch in diameter. Although many smaller tools are shorter, we’ve had success using a heat shrink with a longer holder. This approach eliminates vibration and provides a longer reach, allowing us to reach deep into pockets.

We’ve also found time savings when running these new cutting tools on our five-axis technology. This means our craftspeople spend significantly less time in the setup, which reduces the price we quote to customers. It also means less downtime for our machines.

What is your number-one challenge with cutting tools, and how are you working toward solving that challenge?

Dumoulin: We operate in a highly competitive market and believe measuring our machining efficiency is enormously valuable. This includes the cost we pay for cutting tools, which is one of our largest operating expenses. Recently, we improved our visibility in this area by installing Amper software to monitor and track production metrics of our machines. This unique IoT software provides real-time analytics across our entire manufacturing operation. For example, we are currently reengineering our inventory system and will soon have a cutting tool inventory based on usage rather than intuition. Amper software gives us a deep dive capability to have a granular understanding of set up times, causes of machine downtime, tool longevity, etc.

We also endeavor to stay up-to-date with emerging technology—both hardware and software. To address this challenge, we have become more involved with our vendors. Our objective is to educate ourselves on new products and best practices that improve our capabilities and deliver world-class products to our customers.

How do you see cutting tool technology evolving in the moldmaking industry over the next three to five years?

Dumoulin: We expect continued advances in technology will drive improvements in cutting tool accuracy and increase tool longevity. The first example we’d offer is coatings. We already see new coatings that reduce heat in a meaningful way. Another example is indexable cutting tools. We’re now able to get four uses out of each insert, which is a significant efficiency pick up.

More broadly, mold designers will stretch the limits of new software to design even more complex molds for evolving customer (consumer) needs. We also expect molders will be using new compounds. In turn, these developments will require moldmakers to remain agile with their approach to cutting tools, machining hardware and CAM software.

Related Content

Laser Welding Versus Micro Welding

The latest battle in finely detailed restoration/repair of mold materials.

Read MoreSolving Mold Alignment Problems with the Right Alignment Lock

Correct alignment lock selection can reduce maintenance costs and molding downtime, as well as increase part quality over the mold’s entire life.

Read MoreThe Benefits of Hand Scraping

Accuracy and flatness are two benefits of hand scraping that help improve machine loop stiffness, workpiece surface finish and component geometry.

Read MoreFundamentals of Designing the Optimal Cooling System

The right mold components can help improve mold cooling and thereby produce higher-quality parts.

Read MoreRead Next

MMT's 2020 Leadtime Leader Award Winner Is ...

Precise Tooling Solutions of Columbus, Indiana!

Read MoreVIDEO: Official Announcement of MoldMaking Technology's 2020 Leadtime Leader Award Winner!

Each year, the moldmaking industry recognizes excellence in mold manufacturing with MoldMaking Technology’s, Leadtime Leader Award. It’s not just about being the shop with the shortest delivery times. It’s about what you do with what you have. Meet this year’s winning shop!

Read MoreSnapshot of Why Precise Tooling Solutions is MMT's 2020 Leadtime Leader Winner

Here is a quick look at some of the reasons this small specialty manufacturer took the title this year.

Read More

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=970;quality=90)