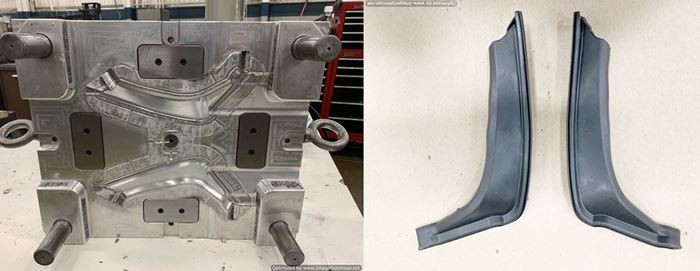

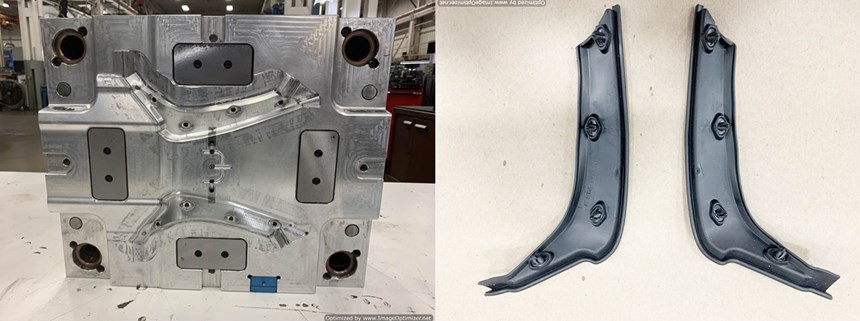

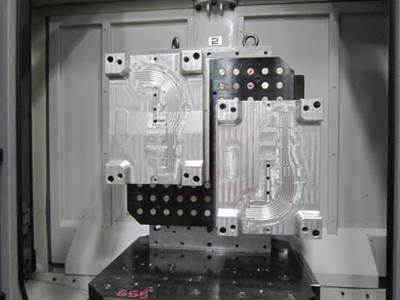

Midwest Mold Services Inc. (Roseville, Michigan) builds prototype and production tools with both aluminum and steel alloys for injection and compression molders. The shop recently produced a 1+1 injection tool for an automotive molder, which was tasked with producing a low-volume spoiler seal in a thermoplastic vulcanizate (TPV). As is nearly universally the case in automotive, the molder was under tight pressure from its OEM customer to reduce cost. Although the tool worked well, the molder asked if the Midwest team could suggest ways to reduce cycle times to help ease cost pressures. The molder already had tried different TPVs to see if a material change could help. The challenge was that a single large cold sprue fed a cold runner, which in turn fed two cashew gates to produce two seals per shot. While not especially large, the 9 by 3-inch/23 x 8.0 cm seals were contoured parts with geometry and featured four insert-molded polyamide 6/6 (PA 6/6, also called nylon) fasteners per cavity. The 0.31-inch/7.94-mm diameter sprue was 4x thicker than the seal, whose nominal wall was 0.0-inch”/2.0 mm. Hence, cooling the sprue became the rate-limiting step, making it difficult to shorten molding cycles and eject parts faster without causing stringing from the still-cooling sprue.

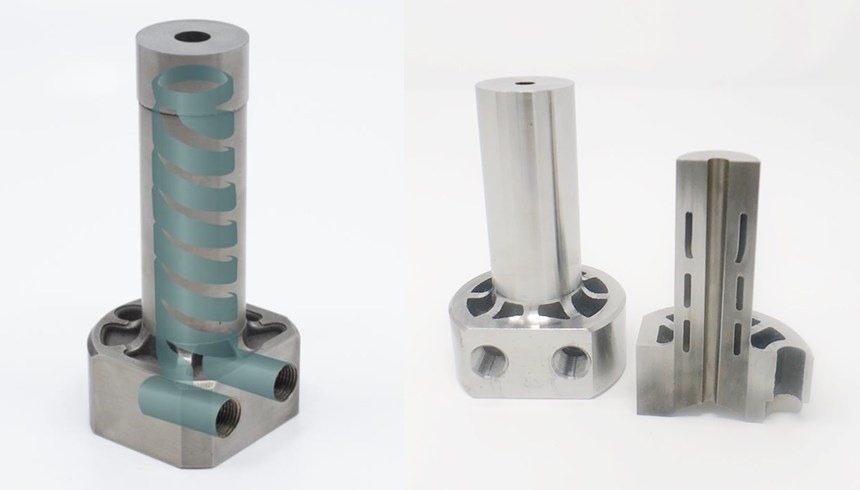

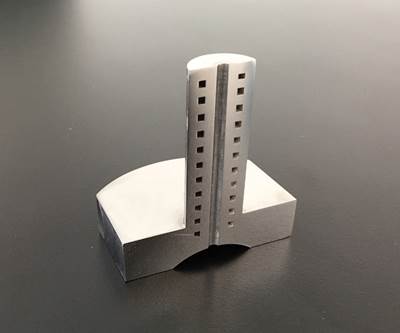

Because the cooling channel’s geometry is too complex to gun drill, which is limited to straight lines and right angles, the entire sprue bushing must be additively manufactured using a process called direct metal laser sintering (DMLS).

“Typically, for a part like this, we’d have used valve gates instead of cashew gates and gated directly into the part to improve cycle times,” explains Doug Carmer, Midwest Mold sales director. “The problem was that the entire cavity side of the part was a Class A surface, which meant that, to produce an aesthetically acceptable surface cost-effectively, we could only use cold-runner gating options.” Carmer and Gary Driscoll, Midwest VP—operations sat down and started looking through part catalogues to see what options they could offer their customer. “We didn’t think we’d get what we wanted with performance metals, as we’d only had marginal success with them previously,” adds Carmer. “We also saw water jacket-wrapped sprues, but we didn’t want to have to tear up the tool, which wasn’t particularly large, and our experience with any kind of O-rings, as you’d have in the water-jacket option, is that eventually they always leak.”

Midwest mold services

At last Carmer and Driscoll discovered what was then a new technology — a conformally cooled (cold) sprue bushing in a part catalogue. The product was said to be ideal for situations where cooling a large sprue mass that fed a small part was slowing down ejection. They asked if their customer wanted to try it and got the go-ahead.

Conformal Cooling: Putting Water Where it’s Needed

Whether it’s applied to molds or sprue bushings, what makes conformal cooling so effective versus traditional cooling methods is that it permits cooling channels to be placed exactly where they’re needed and where CAE results specify. Typically, channels follow the shape or profile of whatever needs to be cooled and can be positioned far closer to hot spots than is possible with conventional baffles and bubblers (in the case of molds) or gun-drilled channels (in the case of sprue bushings). This, in turn, makes it easier and faster to pull heat out of both molten plastic and metal tooling. Since the hold step in injection molding can account for as much as 80% of the total cycle time, according to injection molding training consultancy RJG Inc. (Traverse City, Michigan), by shortening the hold segment, molders can eject solid parts faster and achieve shorter overall cycle times, helping to improve throughput and press utilization rates.

In the case of the conformally cooled sprue bushing, a complex spiral channel winds around the interior of the structure, just outside the central channel where molten plastic flows. This puts cooling water much closer to the molten sprue than water-jacketed sprue bushings can manage, and the channel’s design also covers more of the area of the sprue. Because the cooling channel’s geometry is too complex to gun drill, which is limited to straight lines and right angles, the entire sprue bushing must be additively manufactured using a process called direct metal laser sintering (DMLS).

Payback can be really swift, with some molders seeing an ROI in a matter of weeks or even days depending on the application.

When Big Sprues Limit Cycle-Time Options

The conformally cooled sprue bushing was designed and is sold by PCS Co. (Fraser, Michigan), a manufacturer and distributor of mold components, mold bases, hot runner products, and molding supplies for the plastic injection and die-casting industries. The sprue bushing’s patented spiral cooling channel was produced via additive manufacturing by PCS’s partner/supplier. PCS says it was the first company to offer conformally cooled sprue bushings, which work with any thermoplastic molded via cold runners. Produced in H-13 tool steel that’s hardened and polished, these products are intended to be drop-in replacements for standard B and U series cold sprue bushings and are available from PCS in 10 of industry’s most popular sizes, although the company says that custom sizes are available. PCS also offers conformally cooled gate inserts for molds using hot runners.

“We’ve had good success introducing this technology to the marketplace due to the considerable savings that are seen when the sprue is limiting cycle time,” notes Kelly Beauchamp, PCS key account manager. “On average, we’ve seen 30 percent cycle-time savings, although savings can be as low as 15 percent and as high as 80 percent depending on the application.”

“This can be a good solution for molders who need to reduce cycle times to stay competitive in their markets,” adds John Harding, PCS sales manager. “Accordingly, it’s priced higher than conventional cold and hot sprue bushings because, on the one hand, additive manufacturing is a slower and more costly production process than conventional machining and because, being a unique product, there is some barrier to entry, including the cost of purchasing the additive manufacturing printer. On the other hand, payback can be really swift, with some molders seeing an ROI in a matter of weeks or even days depending on the application. With cooling accounting for 70-80% of the injection molding cycle, if you can impact the cooling process, you can greatly improve cycle time. Of course, the key is finding the correct application where cooling a big sprue that feeds a small part is slowing down the ability to eject faster.”

Easy Install; Perfect Solution

“We were really surprised at how easy it was to install PCS’s conformally cooled sprue bushing,” Carmer continues. “We didn’t connect it to existing water circuits. All we had to do was put a couple of pipes into the clamp plate to feed the water, and our customer added another set of jumpers in their water setup to cool the sprue even faster. And since it has no O-rings, it doesn’t leak. It worked perfectly and reduced our customer’s cycle time. For bigger jobs where you’re using robotic handling, it also would keep your equipment from getting gummed up. We’ll definitely recommend it to anybody having a similar problem.”

Related Content

The Connector Conundrum: 3D Printed Mold Tooling’s Role in Innovation

ReelView Fishing faced an electronics obstacle in the development of its new technology for underwater video. Additive manufacturing for moldmaking enabled the speed necessary to iterate to a solution.

Read MoreHow to Supply Cooling to Additive Tooling

Additive tooling provides limitless options for cooling a mold’s difficult-to-cool areas.

Read More3D Printing Speeds Prototyping and Shifts Talent to Production Tooling

A digital approach to prototyping using 3D-printed tooling accelerates product development and frees up mold builders for production tooling work.

Read MoreMMT Chats: The Connection Between Additive Manufacturing Education and ROI

This MMT Chat continues the conversation with Action Mold and Machining, as two members of the Additive Manufacturing team dig a little deeper into AM education, AM’s return on investment and the facility and equipment requirements to implement AM properly.

Read MoreRead Next

Think Big to Narrow Down Your True Markets

“The educational training, resources and system of prospecting for new accounts were the most valuable things that came from working with MMTC.”

Read MoreCooling of the Sprue

Using conformal cooling in sprue bushing design may be one solution for reducing cycle times.

Read MoreThe Business Side of Moldmaking

This shop’s experience shows that skilled people and the most sophisticated machinery go only so far.

Read More

.jpg;width=70;height=70;mode=crop)