How to Better Utilize Your Existing Equipment

It is time to begin to rebuild capacities and get the highest utilization out of your current shop equipment.

For companies that have survived this recent recession and are dealing with the industry’s continuing skilled workforce issue, it is time to begin rebuilding capacities and getting the highest utilization out of your existing equipment. Now it is necessary to look into alternative solutions and figure out how automation fits into your business. Many mold shop owners say things such as, “I don’t do production work, so I don’t need automation.” This is where the understanding of how automation can help comes into play.

Automation is not something to be feared; it needs to be considered carefully. The very first thing to implement would be a repeatable, palletized workholding system. A company needs to consider the processes to be automated (e.g., EDM, milling or grinding). Then ask if the machines you are considering can be made automation-ready, which involves a discussion with the equipment OEM. Many machines can be retrofitted in the field to be made automation-ready.

Automation may seem overwhelming at first, but it is not as daunting as it seems. The key to success is planning properly and finding the right integration partner to work with. This partner—whether it is an automation manufacturer or integrator—should be a supplier that can bring the right tools to the table to fit your requirements and someone who can work closely with you to satisfy the needs of your company. Some integrators can offer all the needed resources from a single supplier; others may need to involve third-party products.

Automation Solutions

Today’s automation solutions are flexible and aimed at the type of work being done in mold and die shops, which is not high-volume part production, so one thing to keep in mind is that these systems allow for single piece or multiple piece jobs to be processed.

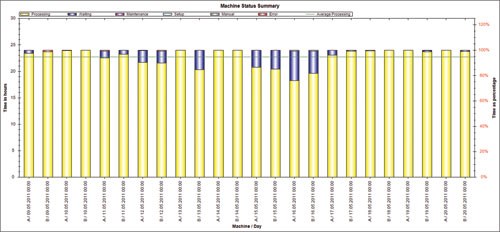

A single workpiece or many can be set up and run while the lights are out. This frees operators up to perform other tasks, becoming more productive. Automation will increase the utilization of your existing equipment by 20 to 30 percent, and in some cases even higher (see Chart 1).

Most shops already use forms of automation without even realizing it. It is perfectly acceptable as a standard practice to mount EDM electrodes on a repeatable tooling system and use an automatic electrode changer to change electrodes during the burn process. A CNC mill or lathe that has a toolchanger on it is just another form of automation.

There are also many different types of handling units or robots available from the very simple to the more sophisticated multi-machine systems. Single machine systems can be adapted to virtually any machine and operate to change work in and out of a single machine easily. These are no more than a pallet pool that work is set up on outside of the machine while other jobs are running. Programs are organized in the machine control and the operator turns the lights off and goes home.

Multi-machine systems allow for multiple machines and multiple tooling styles to be stored and loaded into the machines. For example, it is common to have a robot between two EDMs changing electrodes and workpieces on both machines or two milling machines or a combination of both.

Multi-machine linear systems are handling units that travel on a rail and can handle many machines of different types and organize the work between them. It becomes a bit more intensive to plan the work because of the number of pallets and fixtures that are in process through the automation cell of this type. To better organize this there is available automation cell management software that will organize the flow of work through the automated cell. A project will be built inside the software that contains the programs, offsets and data pertaining to a specific job that is to be run through the automated machines. Once the job is loaded to the machine via the robot, the proper information from the previously built project will be downloaded to the control of the machine for execution. All jobs are organized in this way through the software.

Role Changer and ROI

With automation your operators now become managers of automation cells. Instead of just handling the set ups and production of a single machine, they are now managing the workflow of several. Coordinating the work for the off hours and during the attended times becomes a large part of the new responsibilities. It becomes the job of the cell manager to keep the machines running. This creates new and exciting opportunities for your employees, allowing for new challenges and experiences to expand their knowledge and involvement. The cell manager will begin to see where improvements in the processes can be made. This is an important part of their new function and allows them to bring new ideas to the table to increase the efficiency of the company as a whole.

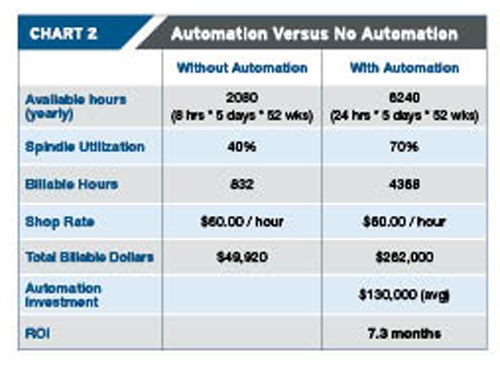

The investment can be significant, so the pay back or ROI is quite important. Chart 2 illustrates an average shop throughput before and after automation is adopted. This is based on one machining center running one 8-hour shift. In this current manual operation the machine is running at a generous 40-percent spindle up time. This is a simple example and does not take into account the cost of operation, but you can see that the amount of time to be gained in one machine is significant when you introduce automation.

Summary

In order for our industry in North America to become and remain healthy, it will take investment by companies in new technologies and processes, including automation. By bringing automation into your business you will utilize your existing equipment and workforce to the fullest.

Related Content

How to Determine the Proper Vent Depth

Vent depth is critical to optimizing mold performance, so here is one approach to finding that elusive right number.

Read MoreWhat You Need to Know About Hot Runner Systems and How to Optimize Their Performance

How to make the most out of the hot runner design, function and performance.

Read MoreHands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.

Read MoreMachining Center Spindles: What You Need to Know

Why and how to research spindle technology before purchasing a machining center.

Read MoreRead Next

Automation Investment Yields Speed and Flexibility

In 2004, Industrial Molds Group took the first steps toward integrating automation to reduce both costs and turnaround times.

Read MoreYour Guide to Smarter, Faster Mold Design

Dive into expert-curated content delivering proven solutions for mold optimization, manufacturability and precision performance.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More