Hot Runners Shrink Leadtimes, Cut Costs

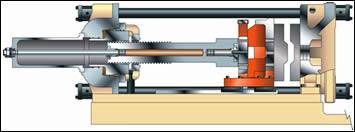

Standardized hot runner system allows the moldmaker to easily configure a system in just two weeks.

Like most mold shops, Advance Mold& Manufacturing (Manchester, CT) is always on the lookout for ways to reduce leadtimes without sacrificing quality. A full-service, contract injection mold manufacturer whose molds run the gamut from molds for small precision products to molds that run in 600-ton molding machines, the company has always relied on a mold building system using standardized mold bases and components in the mold manufacturing process, and recently decided to standardized its hot runner systems to further reduce leadtimes and decrease costs by 15 percent without sacrificing quality.

This 47-year old company—employing approximately 110 people in a 30,000-square foot facility—specializes in multi-component molds, stack molds and unscrewing molds, 60 percent of which are hot runner—for the medical, consumer products and automotive industries. Doug Schneider, vice president of Advance Mold, notes that the company has always relied on hot runner manufacturer Husky Injection Molding Systems (Bolton, ON) for its systems and components. So, as leadtimes continue to shrink due to customer demand, Schneider once again looked to Husky for a solution, which came in the company’s PRONTO program.

The PRONTO program provides configurable hot runners at reduced prices. PRONTO systems match industry standard mold base plate sizes and are available as 1-, 2-, 4-, and 8-drop systems, including non-symmetrical configurations. Each system is built to order with optimized melt channel sizes. Thermal and valve gating is available and nozzle spacing and length is flexible.

“One of our greatest challenges is the pressure to reduce leadtimes and costs,” Schneider comments. “Some of our customers have tried offshore mold purchases and have come back to us again. They are realizing the ‘total cost’ to get their programs into production. They will almost always save on the initial tool cost, but once they add in all of the costs to fully qualify the mold, and the time spent back and forth in the press, it makes much more sense to work with a full-service mold shop that can provide a mold with a hot runner system.

“Customers are demanding more and more,” Schneider continues. “The days of build, squirt and ship molds are almost gone. Now we are required to design, build, provide steel inspection, sample, qualify with cpk runs, etc.” Advance Mold holds .0002 tolerances and has a three-person, in-house polishing department maintaining up to A2 finishes. The company wanted to meet its customers’ demands for faster turnaround time without increasing costs.

PRONTO provides Schneider the same level of performance as a custom-designed Husky hot runner, but at a reduced cost—as much as 20 percent compared to a standard system. “With the shortened hot runner leadtime, the mold designer is able to change design constraints that could impact the hot runner without penalty in cost or leadtime as the hot runner does not need to be ordered until two weeks before it is needed in the assembly phase,” explains Martin Baumann, Husky’s business development and marketing manager. “This gives Advance Mold the added flexibility they need to ensure the job is done right and eliminate any potential costly re-work. What’s more, pitch and nozzle length on a PRONTO system are flexible within a window, giving the company the ability to use standard mold components in their mold design, which also helps reduce costs.”

According to Schneider, Husky’s PRONTO system was instrumental in Advance’s efforts to meet increasing customer demands. “We have been a long time customer of Husky’s, and when they came out with this product, we saw it was just what we—and the industry—needs,” he states.

Hot Runner Rundown

PRONTO hot runner systems are configurable hot halves with plates and manifold systems in 1-, 2-, 4- and 8-drop formats that can be shipped in two weeks. According to Baumann, the components are rapidly produced through a combination of standard parts, automated design practices and lean manufacturing of custom plates and manifolds.

The two-week PRONTO systems resulted from Husky’s systematic lean implementation, Baumann notes, which included the following steps:

- Cross functional teams reviewed the entire value stream from shipment of the product through to initial order entry with a clear objective of reducing leadtimes to two weeks.

- Using Six Sigma tools, manufacturing times and variation at each step in the process was measured.

- Work balancing enabled improved flow and ensured constraint operations are effectively utilized.

- Non-value added tasks were eliminated.

- Standard work procedures were implemented to ensure consistency and flow.

- Visual cueing systems were created to ensure quick response to any flow impediments.

- From start to finish, each team coordinated their efforts to ensure consistent product flow at each handoff point.

- The 50 percent reduction in leadtime was achieved in less than three months, with no impact to existing production or on time performance.

Baumann states that the PRONTO’s quick design affords moldmakers a num-ber of benefits. “Designers are able to include the PRONTO hot runner in their designs prior to ordering as all of the mold and hot runner interface information is available,” he explains. “Customer drawings are completed and delivered in three days after the order is placed; and this engineering information con-firms all of the job-specific information—hot and cold positions, gate details, etc.

Similar to all Husky hot runners, PRONTO systems receive an application review to optimize the hot runner for its specific requirements. Melt channels are sized for throughputs and resin types, residence time, number of color changes and gate styles are evaluated. The systems come in: manifold systems, hot halves with plates, nozzle sizes, pitch (pitch varies, moldmaker can designate pitch), L dimension (length of the nozzle is fully variable within the minimum/maximum range) and a number of gating options. Baumann adds that all of this information can be accessed at www.hotrunners.com.

Baumann lists the four easy steps moldmakers need to take to order a PRONTO system:

- Select a nozzle size

- Select a gating style

- Select a manifold configuration

- Select a compatible mold frame size for plate selection—adaptable to more than 120 different mold frame sizes

The company’s Web site walks the user through this process. Additional considerations are moldmaker interface requirements: electrical, air and water locations; cavity plate interface taps; clamp shots/overhang; and guide pins location. “For a custom system, leadtime is traditionally six weeks,” Baumann says. “With PRONTO, it’s two weeks.”

Advance Mold’s Schneider acknowledges that this system “drastically” reduced the company’s leadtimes by 15 percent. “Despite the downturn in the moldmaking market over the past few years, our total sales have continued to increase,” Schneider states. “We continue to turn a profit.”

Related Content

How to Achieve the Best Mold Finish

A look at factors that impact the polishability of tool steels and recommendations for obtaining a high-gloss finish.

Read MoreHow to Supply Cooling to Additive Tooling

Additive tooling provides limitless options for cooling a mold’s difficult-to-cool areas.

Read MoreMaintaining a Wire EDM Machine

To achieve the ultimate capability and level of productivity from your wire EDM on a consistent, repeatable and reliable basis, regular maintenance is a required task.

Read MoreIt Starts With the Part: A Plastic Part Checklist Ensures Good Mold Design

All successful mold build projects start with examining the part to be molded to ensure it is moldable and will meet the customers' production objectives.

Read MoreRead Next

Get the Most from Your Tooling Investment

Alignment, mold protection, tonnage distribution and injection control are the main elements in the molding machine that could affect your tooling investment.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreYour Guide to Smarter, Faster Mold Design

Dive into expert-curated content delivering proven solutions for mold optimization, manufacturability and precision performance.

Read More